Plastic box injection customization

4 year ago

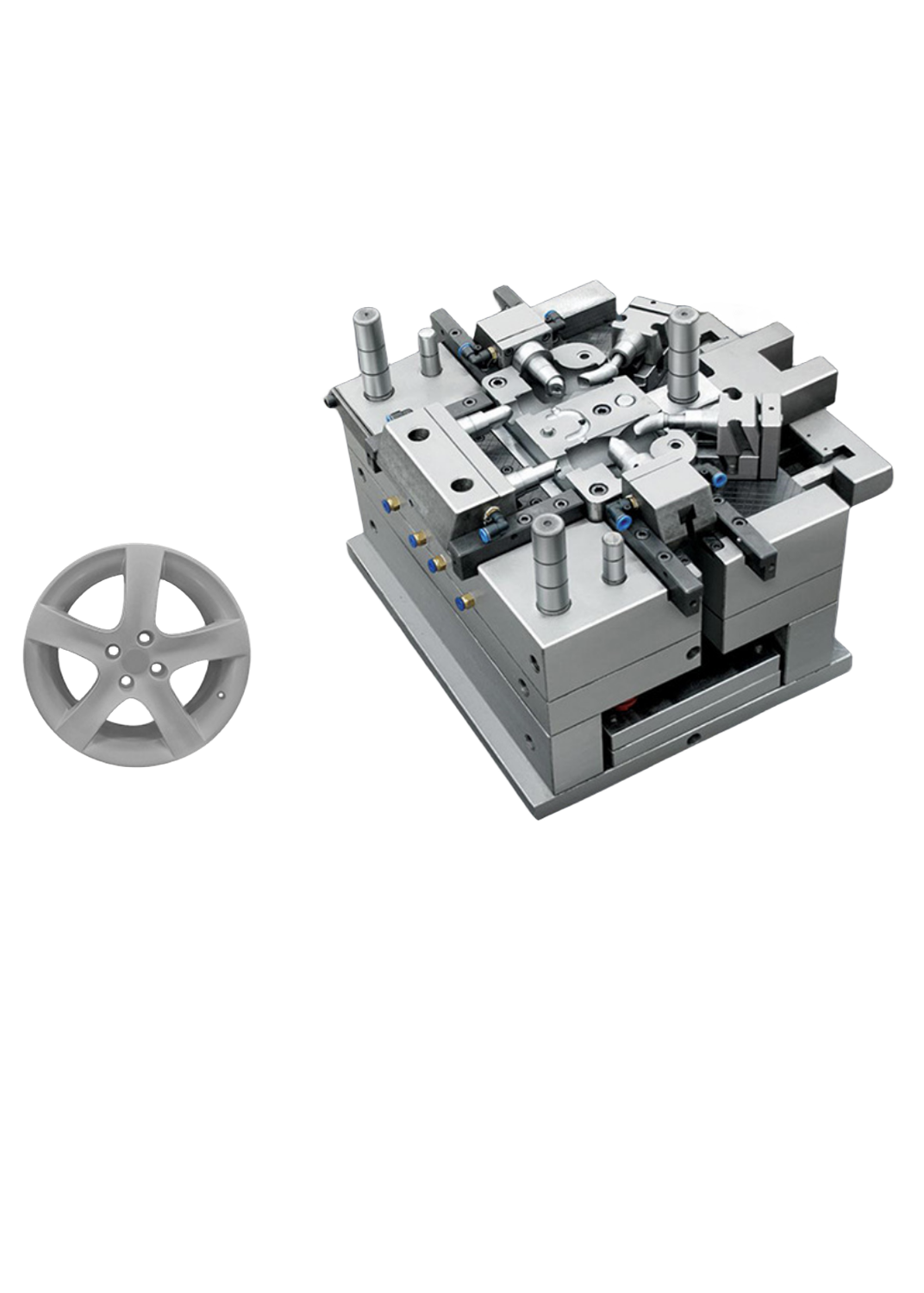

Cavity, core steel :718

Steel hardness :HRC34-38

Die frame steel :50#

Mold standard: DME

Mold cavity number: 1

Injection molding system: large gate

Ejector system ejector rod

Production time : 60 days

Mold life of 500,000 dies

Quality Assurance ISO9001

Material treatment: tempering, quenching and high temperature tempering, so that the workpiece has a good comprehensive mechanical properties, improve the hardness.

Later stage: nitriding (nitriding treatment temperature is low, deformation is very small, no longer need to be quenched with high surface hardness and wear resistance) for you to choose

Advantage 1. High quality products

2. Reasonable prices

3. Deliver on time

4. Good after-sales service

5. Strict quality control

We will provide you with a prompt reply by letter, telephone or fax

Provide quotation and mold design plan in time

Timely technical exchanges

Timely send mold processing pictures and plans

Timely test molds and send samples

Timely delivery

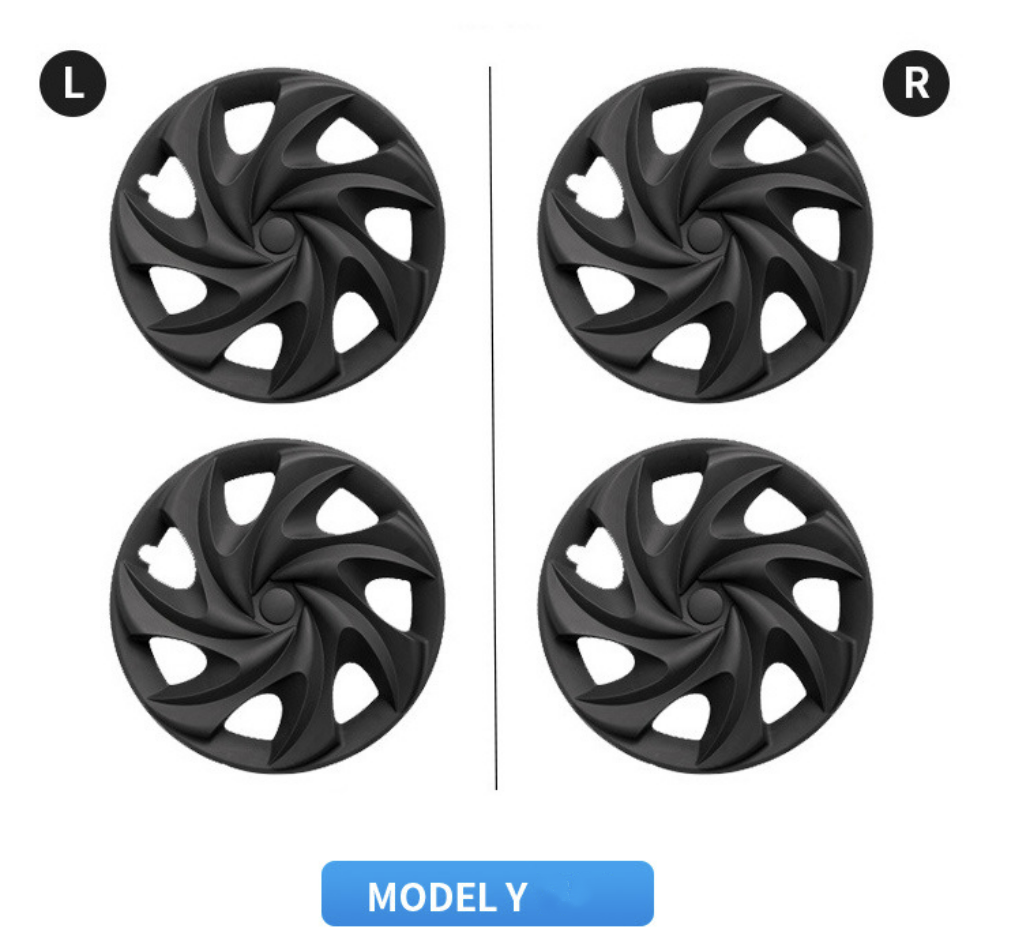

Tesla Hubcap Display Type:

Our service scope refers to plastic three D printing, prototype molds design and manufacturing, two D mold assembly design, Mold-flow analysis, production mold design and manufacturing, plastic injection molding service as well.

Mold processing includes milling machine processing, wire cutting, electric discharge, polishing and other processes. The first is the machining process of the lathe and the milling machine, and the basic parts of the mold are milling to achieve the size of the design requirements.

Then, wire cutting is carried out to cut the outline of the mold. The next step is EDM, which processes small parts of the mold by means of discharge corrosion, and finally polishes to make the surface of the mold smooth and smooth.

After plastic mold processing is completed,, various components are assembled according to mold design requirements, and then the mold is going to be fully tested. The mold test mainly includes the opening and closing action of the mold, the adjustment of the ejector mechanism, inspection of the cooling system, inspection of the hot runner system of the hot runner mold, and so on

After the completion of the mold assembly and debugging, the mold injection molding began. First of all, the plastic particles are added to the bucket of the injection molding machine, and then through heating and the push of the screw, the plastic is melted and injected into the mold cavity, in the mold, the plastic gradually cools and solidifies, and finally forms the shape of the required product.

Similar Video Recommendation

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Zhejiang Ceeto Mold Co.,Ltd.

- *Message:

-

Submit

Main Product:

Plastic Injection Mold,

Plastic Molding ,

Daily consumer plastic molds,

automotive plastic molds,

lighting cover plastic molds,

home appliance plastic molds