PS GPPS foam sheet lunch box cutting machine , Ellie WhatsApp 0086137809127691

3 year ago

the left picture group : semiautomatic production line ;

the right picture group : fullyautomatic production line

The complete production line has two kinds :

semi automatic production line / fully automatic production line ;

A: semi automatic production line includes :

PS foam sheet extrusion machine

semi automatic forming machine

cutting machine

crusher and recycling machine

B: fully automatic production line includes :

PS foam sheet extrusion machine

fully automatic forming & cutting machine

crusher and recycling machine

semiautomatic production line is cheaper but need more labors

fully automatic production line is high effiency and save labors

space : the complete line need 600- 800 square meters

labors : you can arrange 8 hours a shift or 12 hours a shift

A : semiautomatic production line need 8 persons totally ,

that is : 3 persons for sheet machine , 2 persons for forming machine ,2 persons for cutting machine , 1 person for recycling machine

B : fully automatic production line need 6 persons totally ,

that is : 3 persons for sheet machine , 2 persons for forming machine , 1 person for recycling machine

power consumption : semiautomatic production line actual power is 65+45+10+15 KW =135 KW

fullyautomatic production line actual power is 65+65+15=145KW

water need : you can buy cooling tower then it is recycling water , no need to waste much water , it just can evaporate 10 KG per day in 24 hours .

electricity : three phase 380V 50Hz or three phase 220V 60Hz

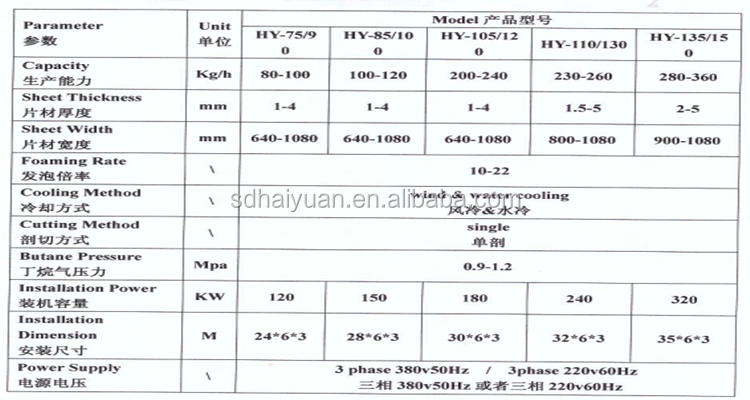

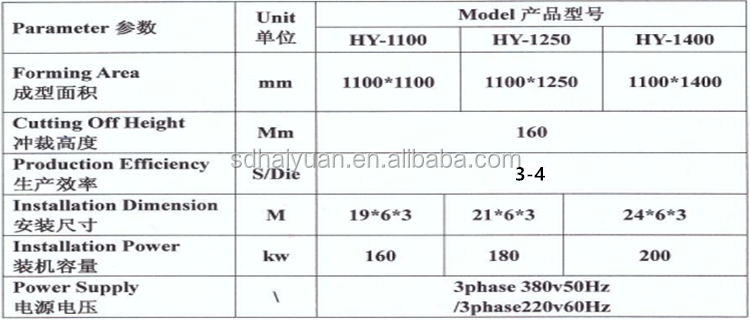

sheet machine / forming machine parameter as following :

haiyuan company introduce :

Our company has product debugging plant,product development plant, and training plant.The production line can produce products : PSP foam sheet, disposable fast food box, foam box, aquatic plate, supermarket plate, cake plate, absorbent meat tray , false ceiling tiles , wine tray , egg tray and other products.Customers ordering equipment , can accept free technical training.

PS foam absorbent tray making machine

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

|

EPE foam sheet extrusion machine

|

|

|

|

formula

|

LDPE ,butane gas , GMS , talc powder

|

|

|

finished products

|

EPE( polyethylene) foam sheet / also called pearl cotton

|

|

|

machine model

|

HY-105 (capacity 100-150KG/hour )

HY-120 (capacity 120-180 KG/hour )

HY-150 (capacity 250-300 KG/hour )

HY-180 (capacity 300-480 KG/hour )

HY-200 (capacity 350-700 KG/hour )

|

|

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- haiyuanmachinery

- *Message:

-

Submit

Main Product:

Foam Food Box Machine,

Foam Plate Making Machine,

PS Foam Sheet Extrusion Line,

PS Foam Absorbent Tray Making Machine,

PS Foam Food Container Production Line,

Thermocol Plate Making Machine

You May Also Like