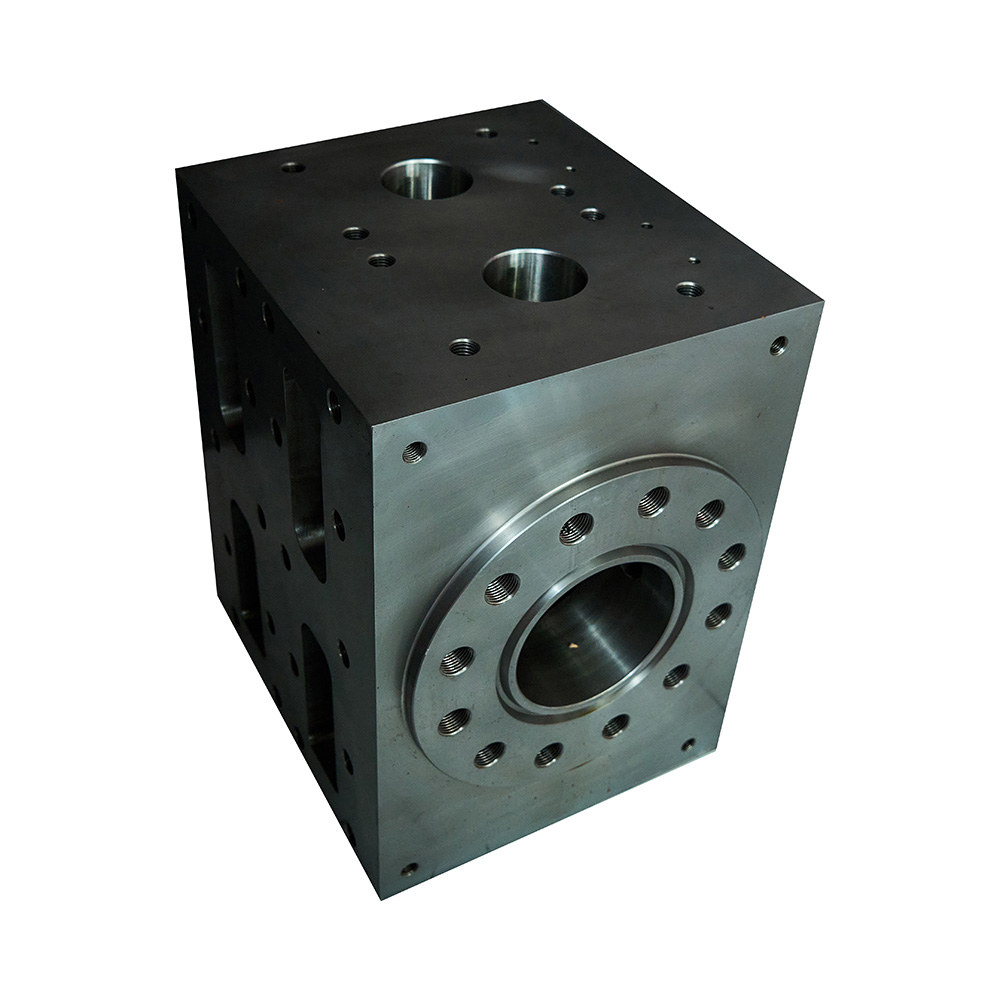

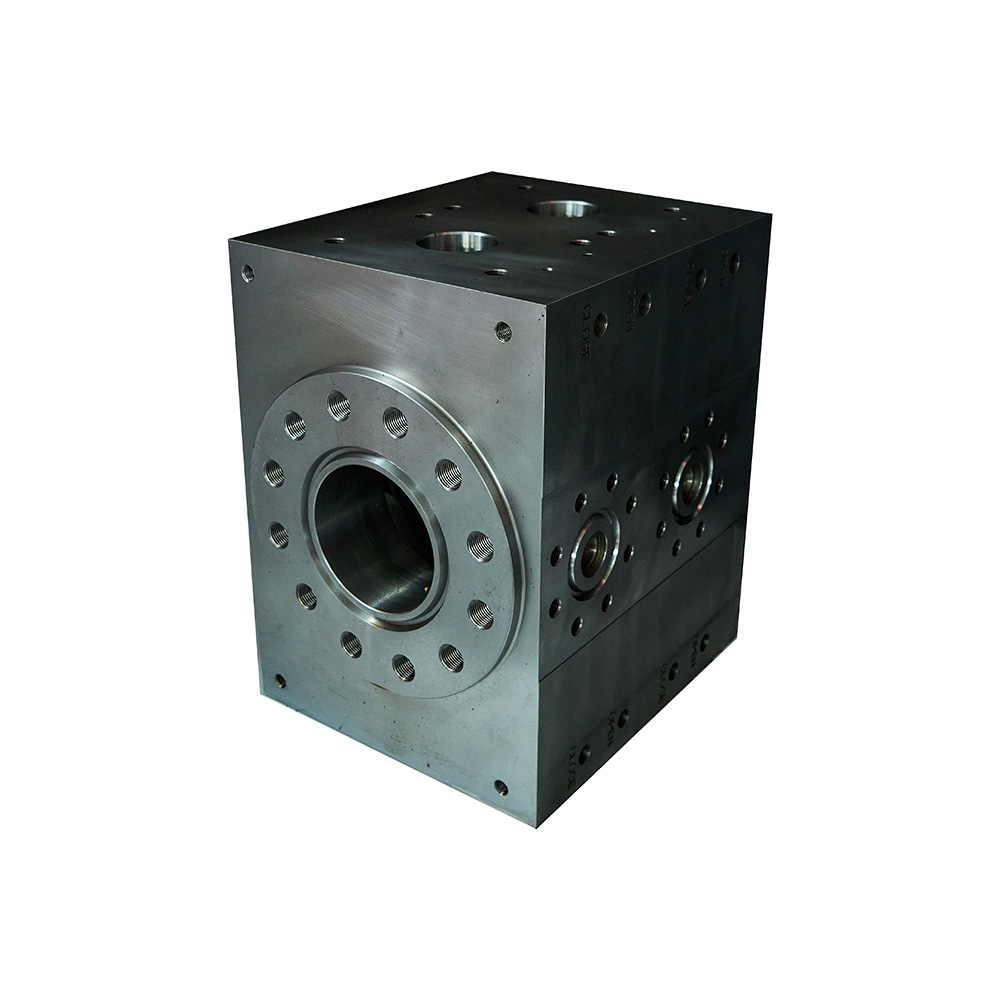

Bop Body

4 month agoStructural design:

The main structure is made of high-strength alloy steel material, which is processed by precision forging and processing technology to ensure that the overall structure has excellent strength and toughness, can withstand extremely high internal pressure and external impact, effectively prevent deformation or damage caused by pressure overload, and ensure the long-term stable operation of the equipment under harsh working conditions.

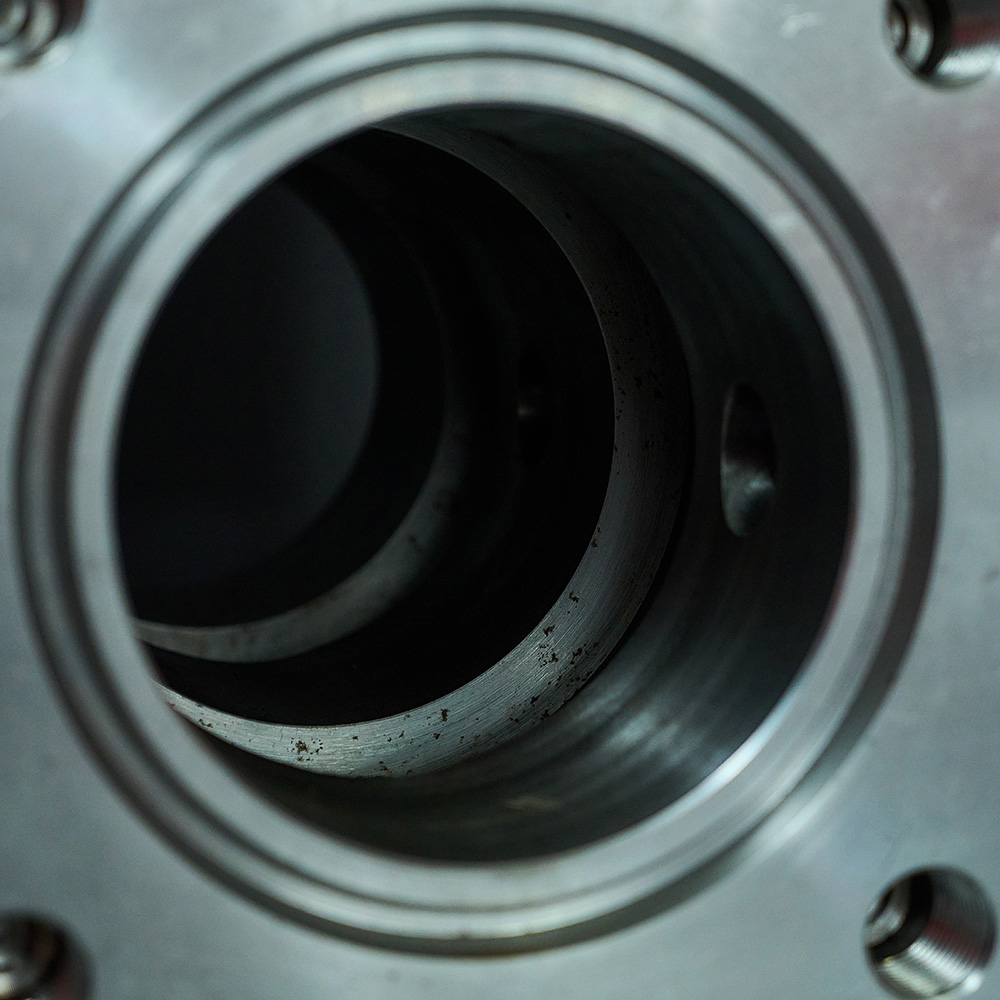

The internal chambers and channels are optimized to ensure smooth flow of fluid inside the blowout preventer, reduce pressure loss and turbulence, and provide precise guidance and support for the movement of key sealing components such as the gate, ensuring that it can quickly and accurately realize the sealing function and effectively block the leakage path of high-pressure fluid in the tubing.

The connection part adopts a standardized flange interface design with high-precision dimensional tolerance and good surface roughness. It can achieve tight and reliable connection with other tubing components, wellhead devices and related auxiliary equipment, ensuring the sealing and integrity of the entire pressure operation system and preventing leakage risks at the connection.

Operation performance:

Matching with the advanced hydraulic control system, the main operating mechanism is simple and efficient, and can quickly respond to the instructions of the hydraulic control system to achieve rapid opening and closing of the gate. The opening and closing of the gate is smooth and smooth, and has a precise position control function, which can ensure that the oil pipe is quickly closed in an emergency, effectively control the wellhead pressure, and provide timely and effective guarantees for the safe operation of pressure operations.

The hydraulic power required during the operation is moderate, which reduces the pressure requirements for the hydraulic system, and also reduces the energy consumption and operating costs of the equipment. The main operating handle or control panel is designed in accordance with ergonomic principles, easy and intuitive to operate, which is convenient for operators to operate quickly and accurately on site, improving operating efficiency and safety.

Scope of application:

It is widely used in various pressure-carrying tubing operation scenarios in the field of oil and gas extraction, including but not limited to well repair, completion, oil testing, production increase measures and other operations of oil wells. It can effectively cope with the pressure-carrying operation requirements of tubings with different pipe diameters and pressure levels. Whether it is conventional oil and gas wells or pressure-carrying operations of complex oil and gas wells such as high pressure, high temperature, and high sulfur content, it can provide reliable blowout prevention control functions to ensure the life safety of operators and the normal operation of equipment, and ensure efficient and safe production of oil and gas fields.

As a petroleum machinery manufacturer, our company also produces Blowout Preventer, Manifold, Cellar Connection, Valve, Pipe Fitting and Control Apparatus, etc.

If you need, please contact us.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Jianhu Fulida Machinery Manufacturing Co. , Ltd.

- *Message:

-

Submit

Main Product:

Oilfield wellhead device,

Drilling and production equipment valve,

Blowout preventer ,

Fracturing Manifold,

Forged steel flange,

Forged parts of wellhead manifold

You May Also Like