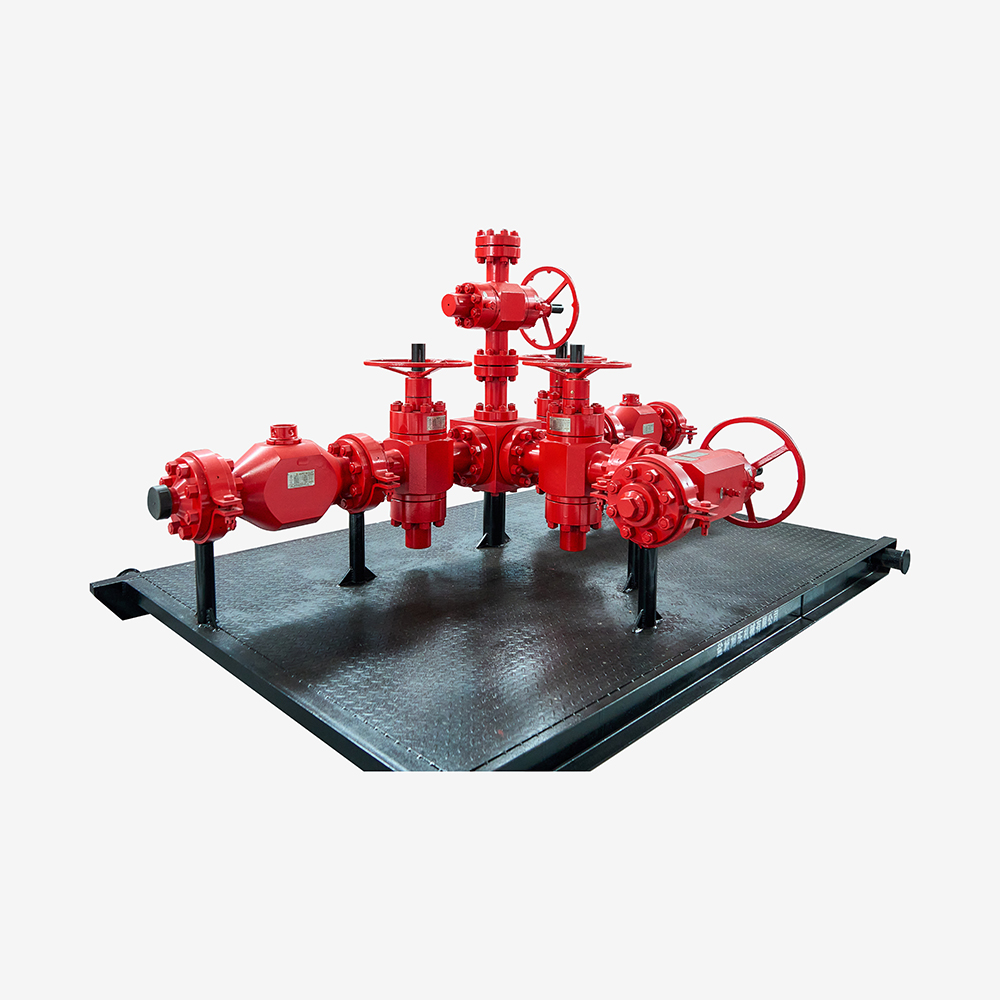

kill Manifold

4 month ago1.Well-killing operation: When the wellhead is fully sealed with a fully sealed gate, heavy mud can be poured into the wellbore to achieve well-killing operation.

2.Prevent fire: When a blowout has occurred, clean water can be injected into the wellbore to prevent fire.

Auxiliary fire extinguishing: When a blowout catches fire, a fire extinguishing agent can be injected into the wellbore to help extinguish the fire.

Structure

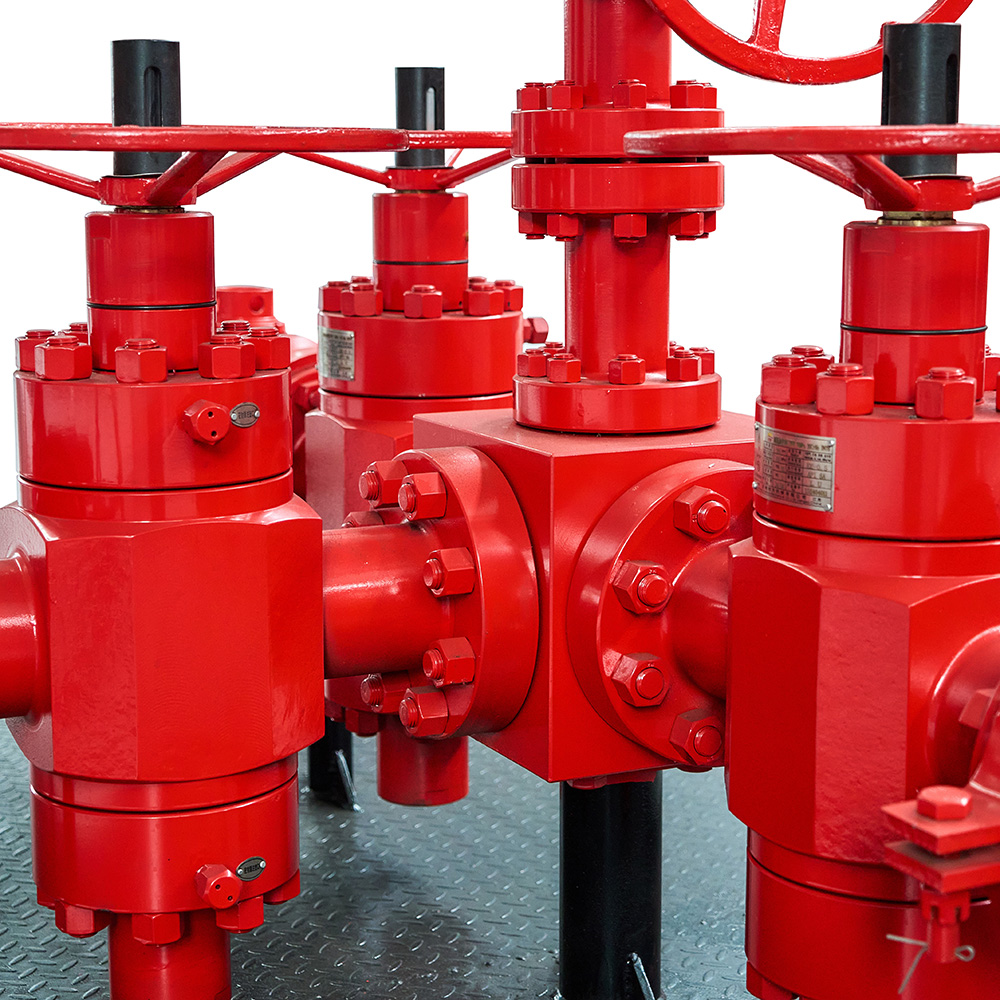

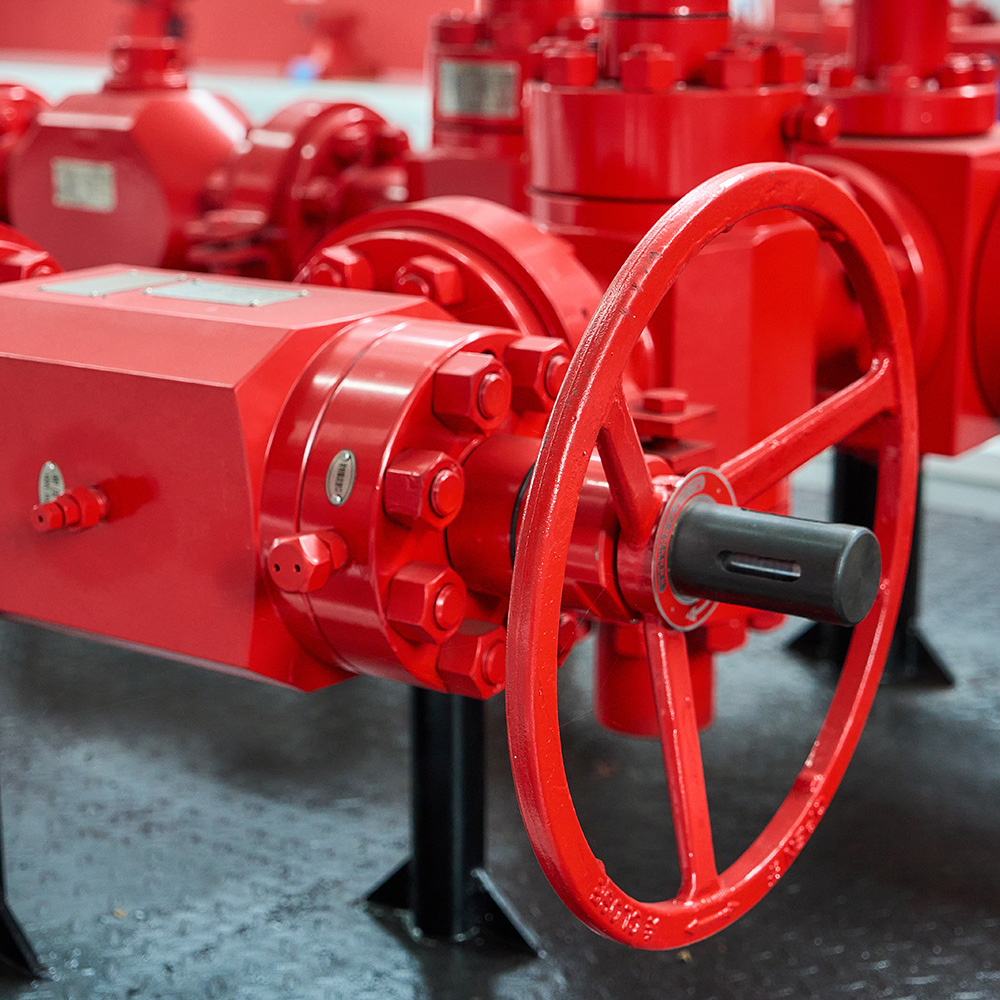

3.Main components: Generally composed of the main spray line and the well-killing pipeline. The well-killing pipeline includes a one-way valve and a flat gate valve. The one-way valve can ensure that the well-killing fluid flows from the mud pump to the casing.

Technical parameters

4.Working pressure: Common working pressures have various specifications, such as 5000Psi, etc.

Working medium: Usually crude oil (gas), mud, hydrogen sulfide, carbon dioxide, etc.

Nominal diameter: The main diameter and bypass diameter have different sizes, for example, the main diameter is 4-1/16", the bypass diameter is 2-9/16", etc.

5.Temperature level: such as PU level, etc.

Material level: Common ones are EE level, etc.

UHV well-killing manifold: For example, the YG78-175 UHV well-killing manifold of Baoshi Machinery has a rated working pressure of 175 MPa and a unique six-channel design structure, which is suitable for the exploration and development of ultra-deep oil and gas resources at the 10,000-meter level.

Vertically movable throttling well-killing manifold: such as the products of Jiangsu Jinshi Machinery Group Co., Ltd., including lifting mechanisms and well-killing mechanisms, which can solve the problem that most of the existing throttling well-killing manifold devices are fixed structures and cannot be adjusted in height, and can be adjusted according to on-site use requirements.

Throttling well-killing manifold with steam-assisted heating function: patented by Jiangsu Jinshi Machinery Group Co., Ltd., using steam as a heat source to heat pipes with cooling and icing risks to ensure smooth and safe flow of the medium inside the pipe.

Rapid positioning and installation of lifting and adjusting well-killing manifold: patented by Jiangsu Shuanghui Machinery Manufacturing Co., Ltd., which solves the problem of difficulty in rapid positioning and inconvenience in changing the direction of the pipe during use of the well-killing manifold.

Integral joint products: The integral joints of some products are integrally forged from high-quality alloy steel. After strict heat treatment, they have the characteristics of compact structure, uniform wall thickness, long service life, beautiful and smooth appearance, strong interchangeability of connection joints, and convenient connection. In addition, thickening treatment is designed in places where the fluid changes direction and the inner wall erosion is serious, such as elbows and joints, to extend the safe service life.

Application scenarios

During the drilling process of oil and gas fields, it is used in conjunction with the throttle manifold and connected to both sides of the blowout preventer. It is a supporting tool for balanced drilling or underbalanced drilling. It is used to control overflow and blowout, implement oil and gas well pressure control, and plays a vital role in the safety of well killing operations.

| Product name | Well Killing Manifold |

| Specification model | 65-105 |

| Implementation standard | API 6A |

| Rated working pressure | 15000PSi |

| Product specification level | PSL1~PSL3G |

| Product performance leve | PR1~PR2 |

| Temperature level | PU, LU |

| Material level | AA~FF |

| Product color | red |

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Jianhu Fulida Machinery Manufacturing Co. , Ltd.

- *Message:

-

Submit

Main Product:

Oilfield wellhead device,

Drilling and production equipment valve,

Blowout preventer ,

Fracturing Manifold,

Forged steel flange,

Forged parts of wellhead manifold

You May Also Like