four links

4 month ago1. Low fluid resistance: The connecting pipe sections of the ball and the valve body are equal, and the ball channel is connected by an arc. When the medium passes through the ball, the fluid resistance is small.

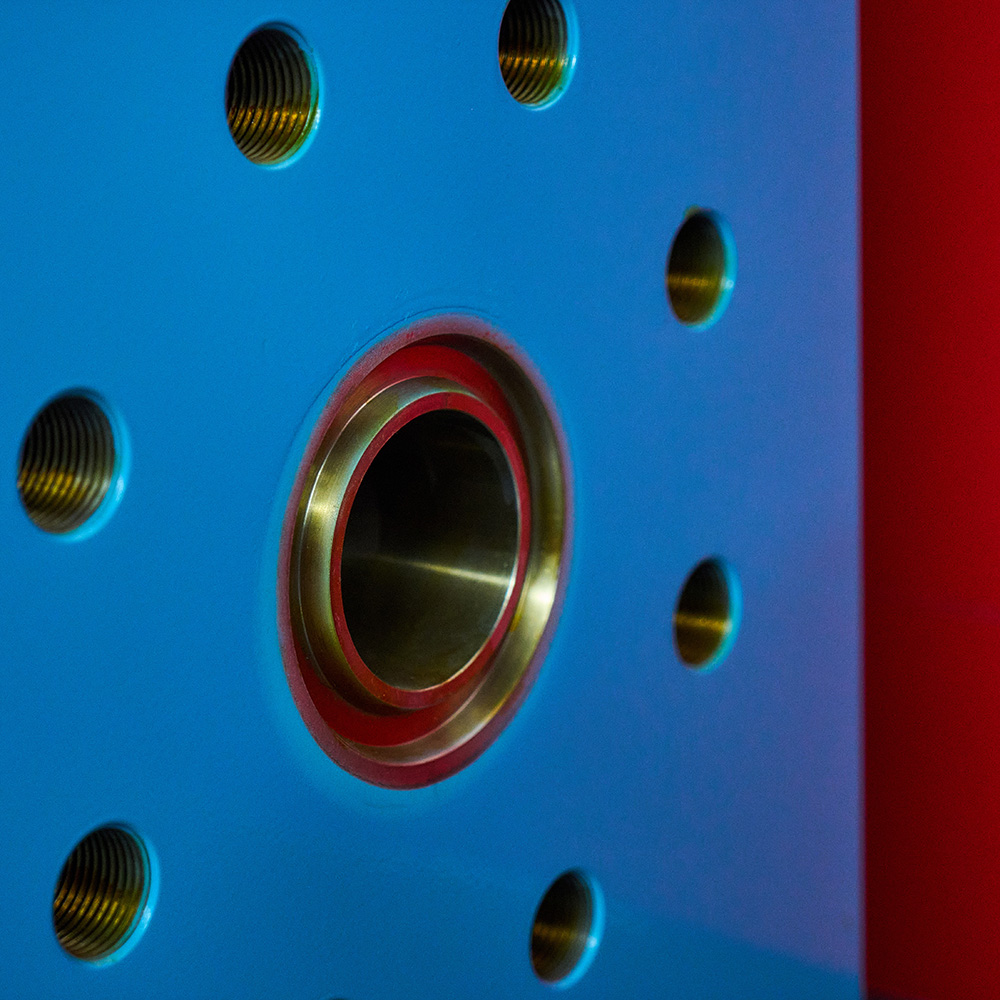

2. Long service life: The valve core and valve stem neck materials of the valve are made of corrosion-resistant materials such as austenitic stainless steel, and the valve seat material is made of PTFE, etc., which can achieve good corrosion resistance and extend the service life of the valve.

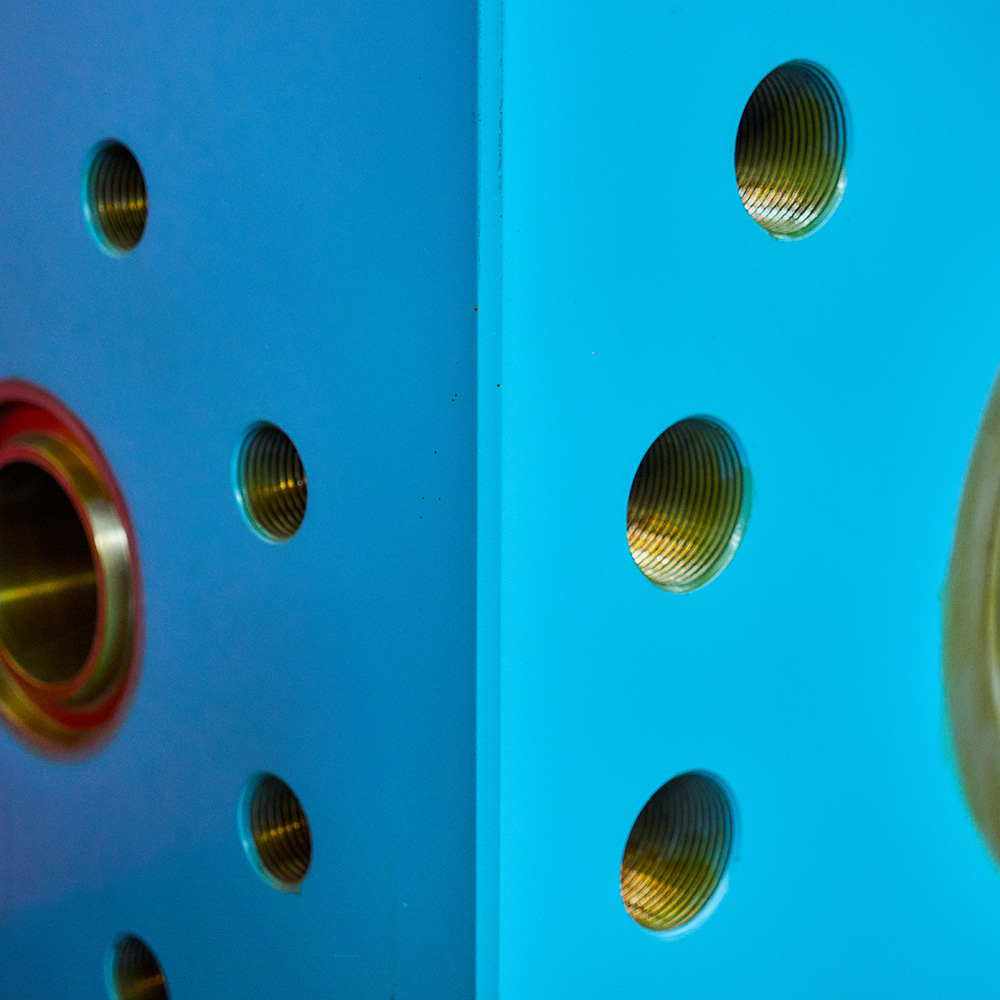

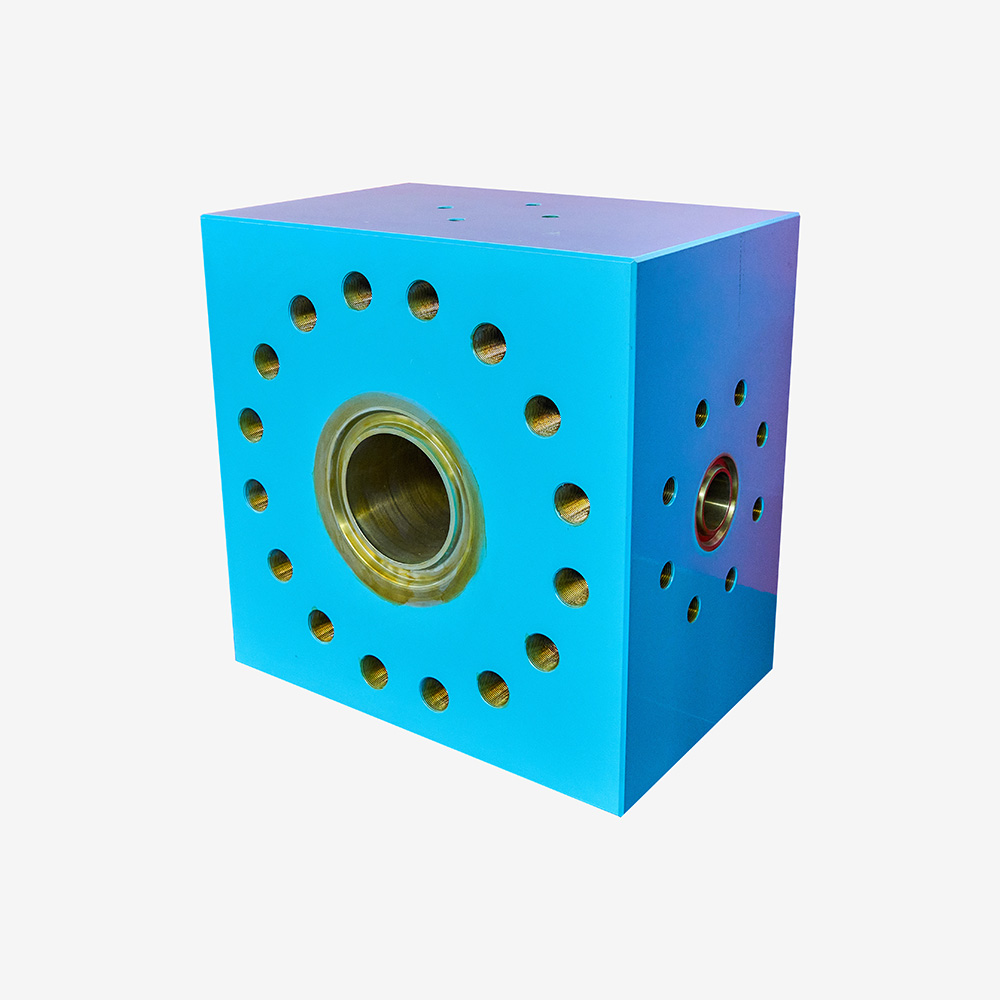

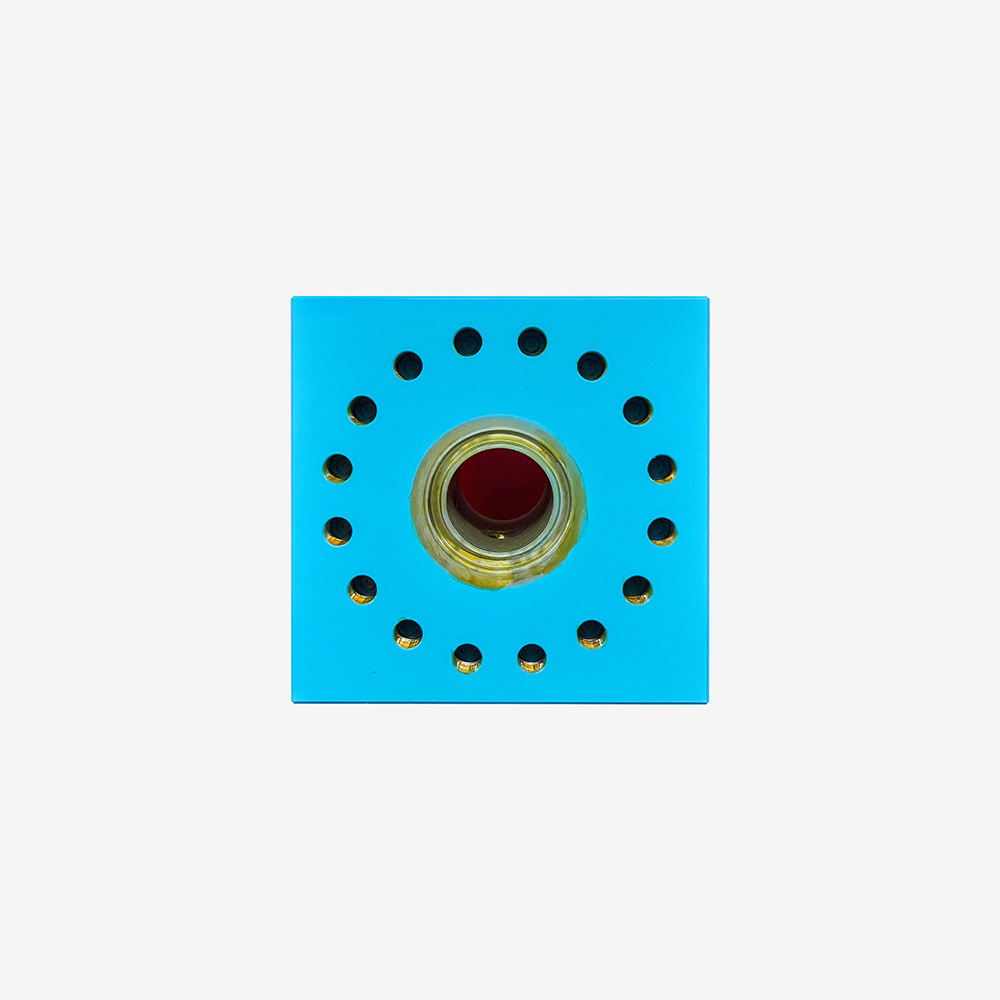

3. Easy maintenance: The ball valve has a simple structure, and the sealing ring is generally movable, which is convenient for disassembly and replacement. For some four-way connection components used in gas wellhead devices, each connection port is installed with a flange, which makes the combination of the entire system simpler and easier to maintain when problems occur.

4. Flexible flow control: Four different flow directions can be controlled independently, and any flow direction can be selected according to actual needs. It is suitable for complex gas production processes and can meet the needs of gas collection, transportation and control in different directions.

5. High safety: According to needs, the ball valve can be designed as an anti-static structure, and a conductive spring is set between the ball and the valve stem, and between the valve stem and the valve body to avoid static electricity ignition and ignition of flammable materials to ensure system safety. In addition, some gas production four-way valves have stable connections, such as the patented products manufactured by Yancheng Shenhua Machinery. The configuration of the anti-slip ring and the plug-in column makes the connection more stable and not easy to fall off, which improves the safety of gas production operations.

Structural composition: It is usually composed of a valve body, a valve cover, a valve stem, a valve core and a sealing ring. The valve core is the most critical part, which determines the switching performance of the valve and the flow direction of the fluid. In the four-way valve, the valve core is usually designed with a multi-layer structure to achieve the switching of multiple flow directions.

Working principle: Taking the common "LL" type four-way ball valve as an example, by rotating the ball 90 degrees, the two inlet and outlet flow paths are converted, thereby changing the flow direction of the gas and achieving the purpose of controlling the gas flow path during the gas production process.

Applicable medium: Suitable for gas media such as natural gas. Some gas production four-way valves can also be used for corrosive and non-corrosive media such as water and oil.

Application scenario: Mainly used in gas production wellhead devices, natural gas transmission pipelines and other gas production related fields. It is a key control equipment in the gas production process, which can realize the precise control of the gas flow direction and flow rate during the gas production process.

| Product name | Casing Head |

| Specification model | 5 1/8 to 3 1/8 |

| Implementation standard | API 6A |

| Rated working pressure | 20000PSi |

| Product specification level | PSL1~PSL3G |

| Product performance level | PR1~PR2 |

| Temperature level | PU, LU |

| Material level | AA~FF |

| Product color | blue |

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Jianhu Fulida Machinery Manufacturing Co. , Ltd.

- *Message:

-

Submit

Main Product:

Oilfield wellhead device,

Drilling and production equipment valve ,

Blowout preventer,

Fracturing Manifold,

Forged steel flange,

Forged parts of wellhead manifold

You May Also Like