A hydraulic pump system with a hollow hydraulic jack is an interesting and innovative design that combines the principles of hydraulic power transmission with a unique structural feature. Let's break down the components and functionality of such a system:

### Components:

1. **Hydraulic Pump**: This is the primary component that generates hydraulic pressure by pumping fluid (usually oil) through the system.

2. **Hollow Hydraulic Jack**: This is a specialized jack with a hollow cylinder or piston rod, which allows for additional functionalities.

3. **Reservoir**: Stores the hydraulic fluid.

4. **Valves**: Control the flow and direction of hydraulic fluid.

5. **Piping/ Tubing**: Connects all the components and ensures proper fluid flow.

### Functionality:

1. **Pressure Generation**:

- The hydraulic pump draws fluid from the reservoir and pressurizes it.

- The pressurized fluid is then directed into the hollow hydraulic jack.

2. **Hollow Hydraulic Jack**:

- **Hollow Cylinder/Piston Rod**: The hollow design allows for several advantages:

- **Pass-through Functionality**: Allows for cables, rods, or other mechanical components to pass through the jack while it is under load. This is particularly useful in applications where alignment or movement needs to be maintained during lifting or pressing operations.

- **Internal Wiring**: Can accommodate internal wiring for sensors or control systems.

- **Reduced Weight**: The hollow design can reduce the overall weight of the jack, making it more suitable for certain applications.

3. **Force Application**:

- As hydraulic fluid is forced into the hollow jack, it pushes against the piston, creating a lifting or pressing force.

- The hollow design does not compromise the structural integrity of the jack, as the force is transmitted through the walls of the cylinder.

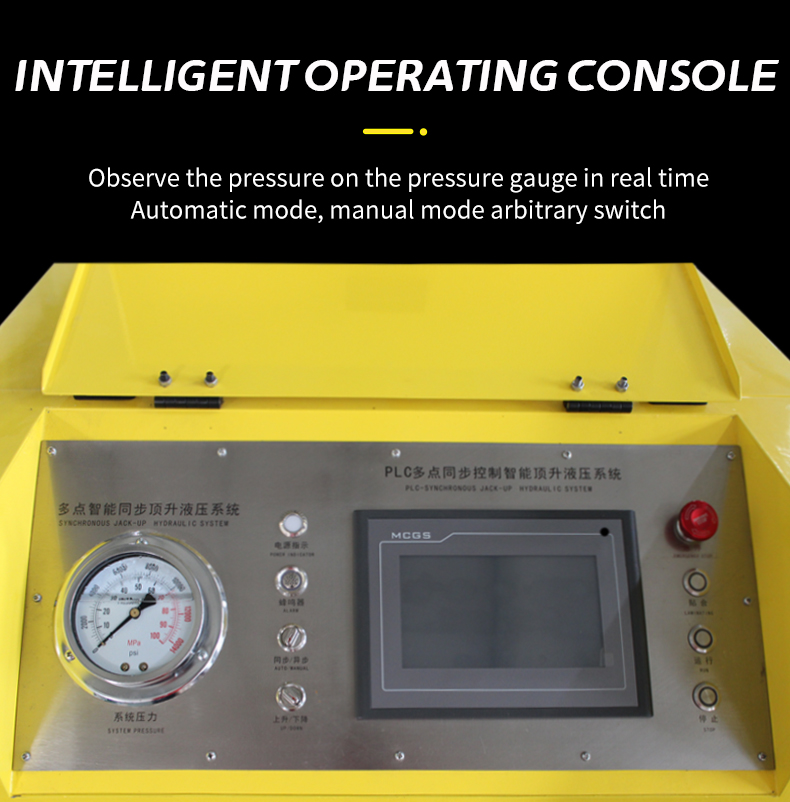

4. **Control and Regulation**:

- Valves regulate the flow and pressure of the hydraulic fluid, ensuring smooth operation and precise control.

- Depending on the application, various types of valves (e.g., check valves, directional control valves) may be used.

### Applications:

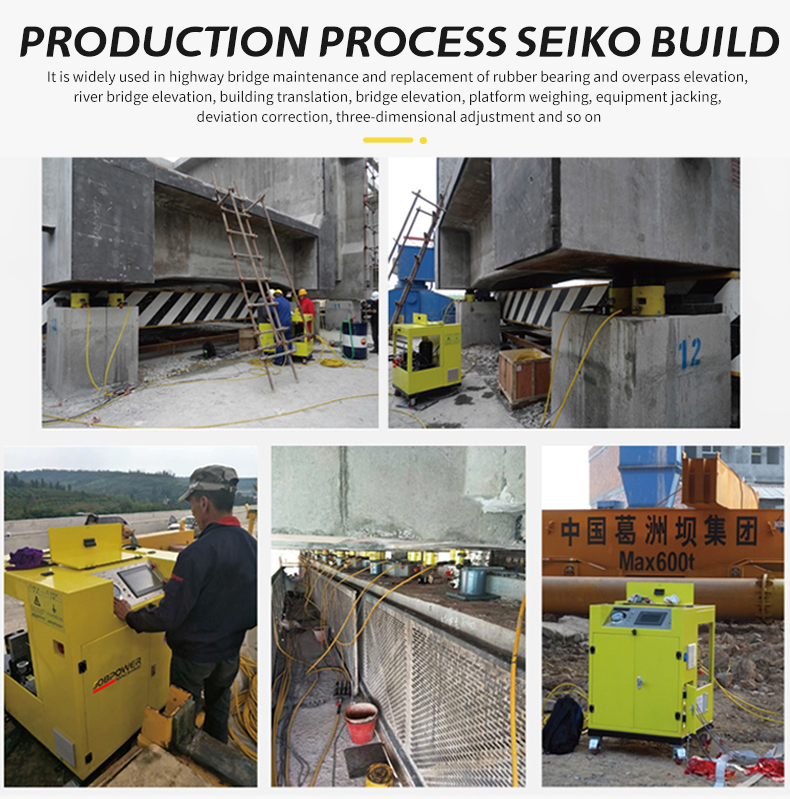

- **Automotive Industry**: For lifting vehicles or aligning parts.

- **Construction Equipment**: For lifting heavy loads or aligning components.

- **Manufacturing**: For precision alignment of machinery parts.

- **Lifting and Pressing Operations**: Where alignment needs to be maintained during the operation.

### Advantages:

- **Precision Alignment**: The ability to pass through mechanical components allows for precise alignment during lifting or pressing operations.

- **Weight Reduction**: The hollow design can make the jack lighter without compromising strength.

- **Integrated Systems**: Can be part of a larger integrated system with sensors and control mechanisms.

### Considerations:

- **Design Complexity**: The hollow design may add complexity to the manufacturing process.

- **Strength and Durability**: Ensuring the jack remains structurally sound under high pressures and loads.

- **Maintenance**: Proper maintenance of seals and valves to prevent leaks and ensure smooth operation.

In summary, a hydraulic pump system with a hollow hydraulic jack offers a versatile solution for applications requiring both high force and precise alignment or movement capabilities. The hollow design provides unique advantages but also introduces specific design and manufacturing considerations.

|

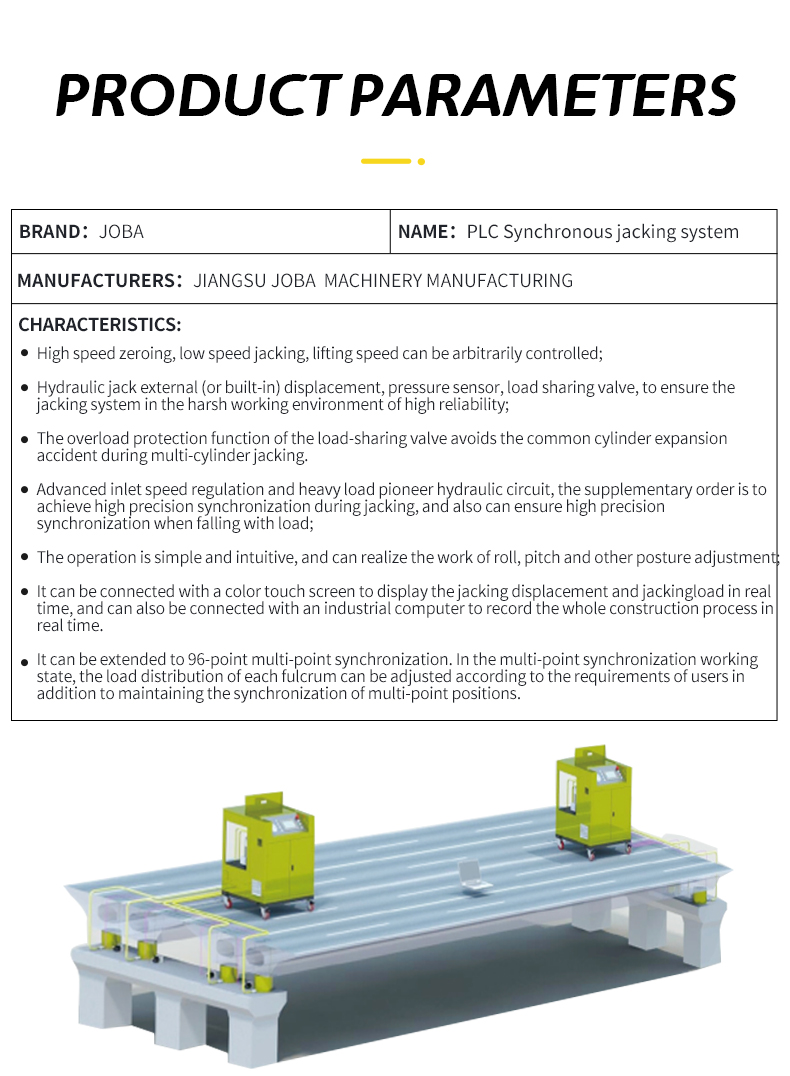

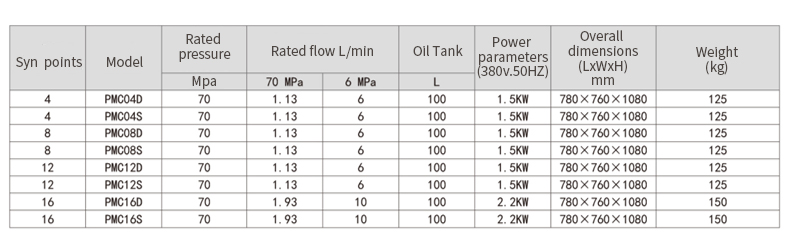

Features of PLC Synchronous Jacking System

|

|

|

1

|

Displacement precision ≤±0.2mm.

|

|

2

|

Working voltage: AC380V/50Hz(Three-phase-Five-wire system).

|

|

3

|

Control voltage: DC24V.

|

|

4

|

Control pattern: frequency conversion speed regulating.

|

|

5

|

Pressure sensor: input DC24V, range: 0-70MPa,output: 4-20mA.

|

|

6

|

Displacement sensor: input24V, range: 0-1000mm, Push-pull.

|