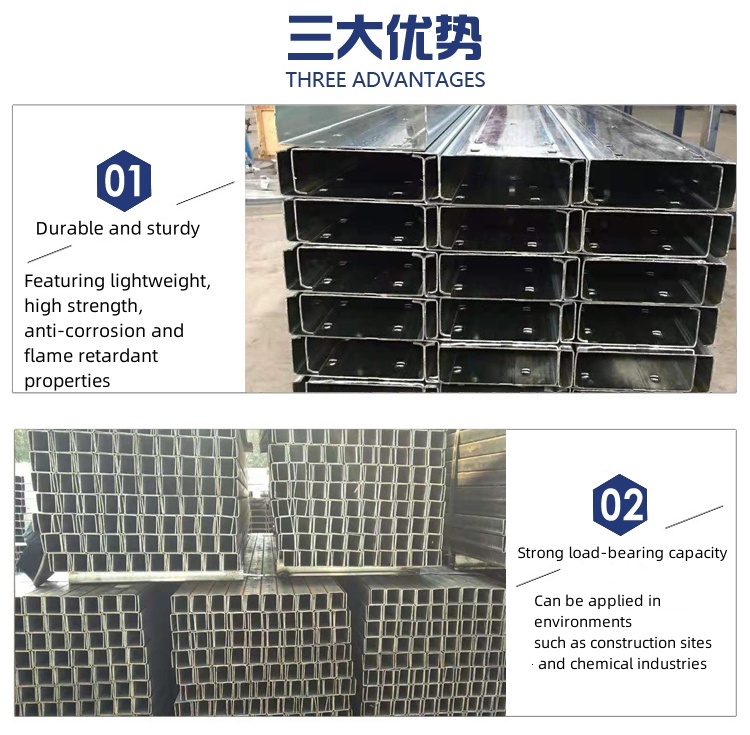

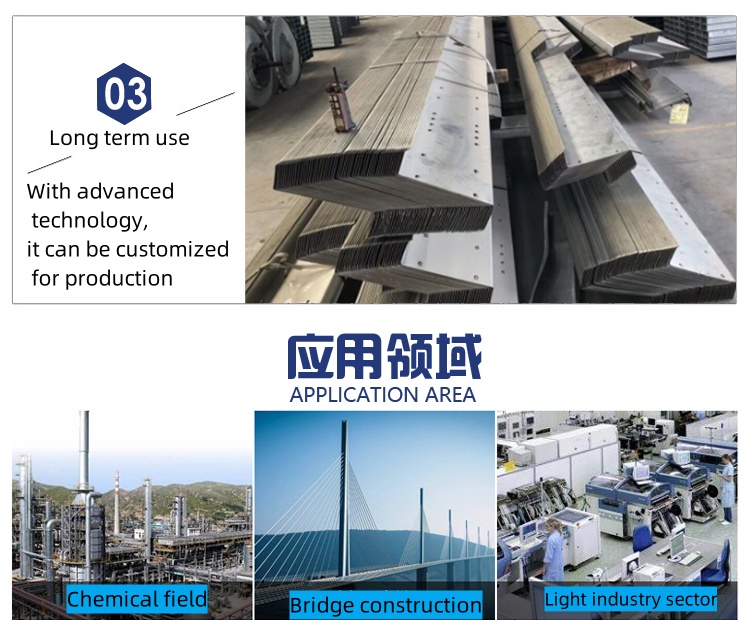

Stacking of square tube warehouse

2 month agoSquare Rectangular Tube Bending Techniques: Precision and Versatility for Your Projects

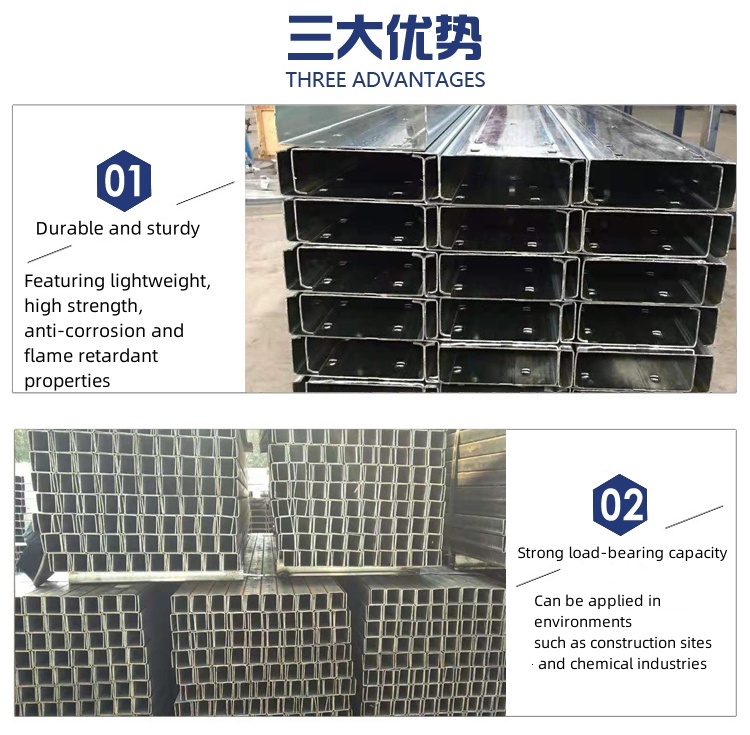

Square rectangular tubes are widely used in various industries due to their structural strength, durability, and aesthetic appeal. However, bending these tubes requires specialized techniques to maintain their integrity and achieve precise shapes. Whether you're working on architectural designs, automotive frames, or industrial machinery, understanding the bending techniques for square rectangular tubes is essential. Here’s a detailed overview of the methods, tools, and considerations involved in bending square rectangular tubes.

1. Common Bending Techniques for Square Rectangular Tubes

a. Rotary Draw Bending

Rotary draw bending is one of the most precise methods for bending square rectangular tubes. It uses a die set to clamp the tube and a rotating arm to draw it around the die, creating smooth, consistent bends. This technique is ideal for tight-radius bends and complex shapes, ensuring minimal distortion and high accuracy.

-

Advantages: High precision, smooth finishes, and minimal wall thinning.

-

Applications: Automotive exhaust systems, handrails, and furniture frames.

b. Roll Bending

Roll bending involves passing the tube through a series of rollers to gradually curve it. This method is suitable for creating large-radius bends and arcs, making it perfect for architectural structures like arches and canopies.

-

Advantages: Ideal for large-radius bends, cost-effective for long tubes.

-

Applications: Greenhouse frames, curved staircases, and decorative structures.

c. Mandrel Bending

Mandrel bending uses a flexible mandrel inserted into the tube to support the inner wall during bending. This technique prevents collapsing or wrinkling, especially in thin-walled square rectangular tubes.

-

Advantages: Maintains tube shape and wall thickness, suitable for tight bends.

-

Applications: Hydraulic systems, aerospace components, and custom fabrication.

d. Press Bending

Press bending is a simpler method where the tube is pressed against a die using hydraulic or mechanical force. While less precise than rotary draw bending, it is cost-effective for larger projects with less stringent tolerances.

-

Advantages: Fast and economical for large-scale production.

-

Applications: Structural frames, fencing, and industrial equipment.

2. Tools and Equipment for Bending Square Rectangular Tubes

-

Bending Machines: CNC-controlled machines for high precision and repeatability.

-

Dies and Mandrels: Custom-designed to match the tube dimensions and bend radius.

-

Lubricants: Reduce friction and prevent damage to the tube surface.

-

Laser Measurement Tools: Ensure accurate bend angles and radii.

Conclusion

Square rectangular tube bending techniques offer endless possibilities for creating functional and visually appealing structures. By understanding the methods, tools, and considerations involved, you can achieve precise bends that meet your project’s demands. Whether you’re working on a small DIY project or a large-scale industrial application, mastering these techniques ensures durability, aesthetics, and performance.

For high-quality square rectangular tubes and expert bending services, contact us today to discuss your requirements!

We also sell various materialssteel plate、Steel Pipe、Welded steel pipe

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Shandong Shifeng Metal Products Co., Ltd.

- *Message:

-

Submit

Main Product:

Stainless Plate,

Alloy Plate,

Abrasion Resistant Steel Plate,

Seamless Tube,

Stainless Steel Tubing,

Square and Rectangular Tube

You May Also Like