china plastic mould

2 month ago

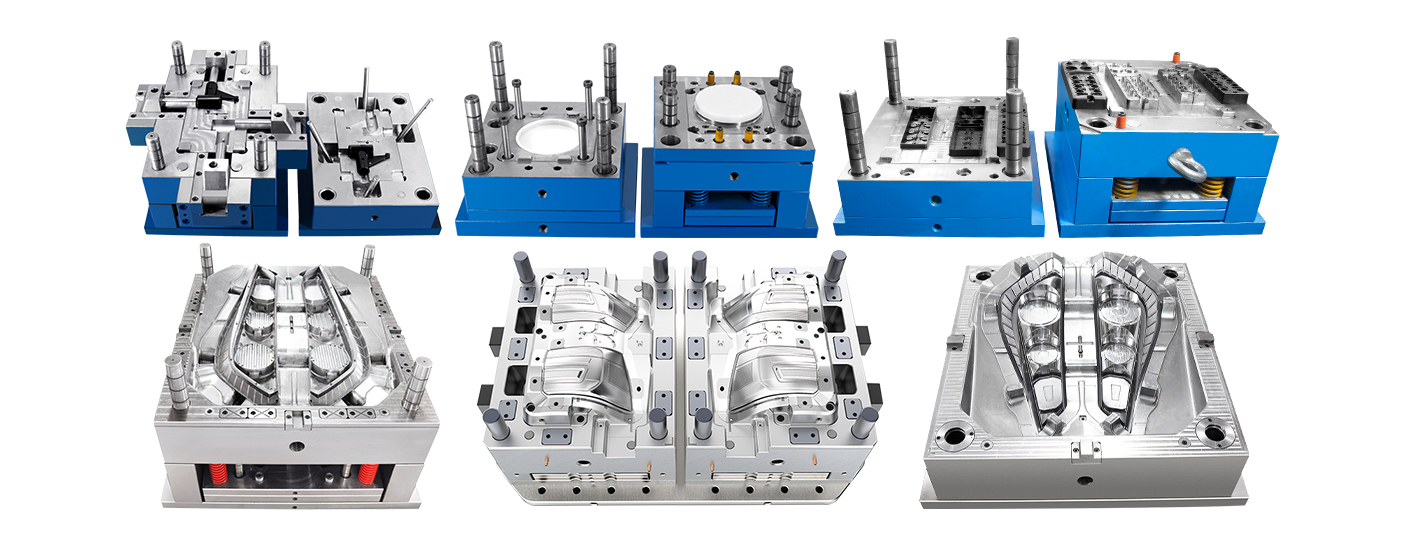

The Working Process of Injection Molding

The injection molding process can be broken down into several key steps:

1. Material Preparation: The journey begins with the selection and preparation of the raw material. Plastic pellets are fed into a hopper, where they are heated and melted through a combination of temperature control and mechanical mixing.

2. Injection Phase: Once the plastic is in a molten state, it is injected into a precisely designed mold under high pressure. This step is crucial, as it ensures that the material fills every part of the mold cavity, capturing all the intricate details of the design.

3. Cooling Phase: After the molten plastic is injected, it must cool and solidify. Cooling channels within the mold help regulate temperature, allowing the material to harden into its final shape. This step is vital for ensuring the structural integrity of the product.

4. Ejection Phase: Once the part has sufficiently cooled and solidified, it is ejected from the mold using ejector pins or plates. A quality inspection is often conducted at this stage to check for any defects or inconsistencies.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Guangzhou One-Stop Engineering Plastics Industries (group) Co., Ltd

- *Message:

-

Submit

Main Product:

CNC Machining Parts ,

Injection Molding Parts,

Plastic Sheets,

Plastic Tubes,

Plastic Rods,

Peek Sheet

You May Also Like