Changing the length of the steel pipes by rolling process

2 week ago

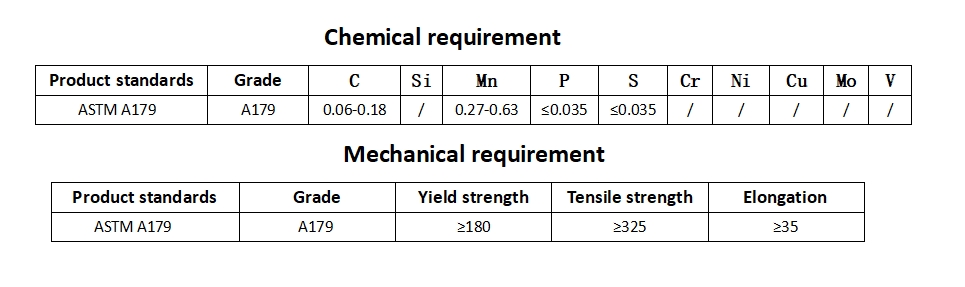

This type of tube is designed for heat exchanger applications and is made of high-quality steel. It follows strict standards from the selection of raw materials to ensure its purity and stability, laying the foundation for subsequent high performance.

Its manufacturing process is exquisite, the tube wall thickness is uniform, and the tube diameter is high. This allows the fluid to flow in a more ideal state during the heat exchange process, reducing the increase in local resistance and uneven flow distribution caused by uneven tube diameter or tube wall thickness deviation, thereby improving heat exchange efficiency.

In terms of corrosion resistance, ASTM A179 heat exchanger tubes are specially treated to effectively resist common media corrosion inside the heat exchanger. Whether it is hot water, steam, or some corrosive chemical solutions, it can ensure the long-term stable operation of the tube, reduce perforation, leakage and other faults caused by corrosion, extend the service life of the heat exchanger, and reduce equipment maintenance costs and replacement frequency.

In addition, it has good mechanical properties and has sufficient strength and toughness to withstand the thermal stress caused by pressure fluctuations, vibrations and temperature changes in the heat exchanger during operation, ensuring reliable operation under complex working conditions. It provides a solid guarantee for the efficient transfer of heat in industrial production and is a high-quality choice for many heat exchanger manufacturers and users.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Baodely Huaian Metal Technology Co., Ltd.

- *Message:

-

Submit

Main Product:

Carbon Steel Pipe,

Low Temperature Steel Pipe,

Boiler Pipe,

Alloy Steel Pipe,

High Temperature Steel Pipe ,

Precision Steel Pipe

You May Also Like