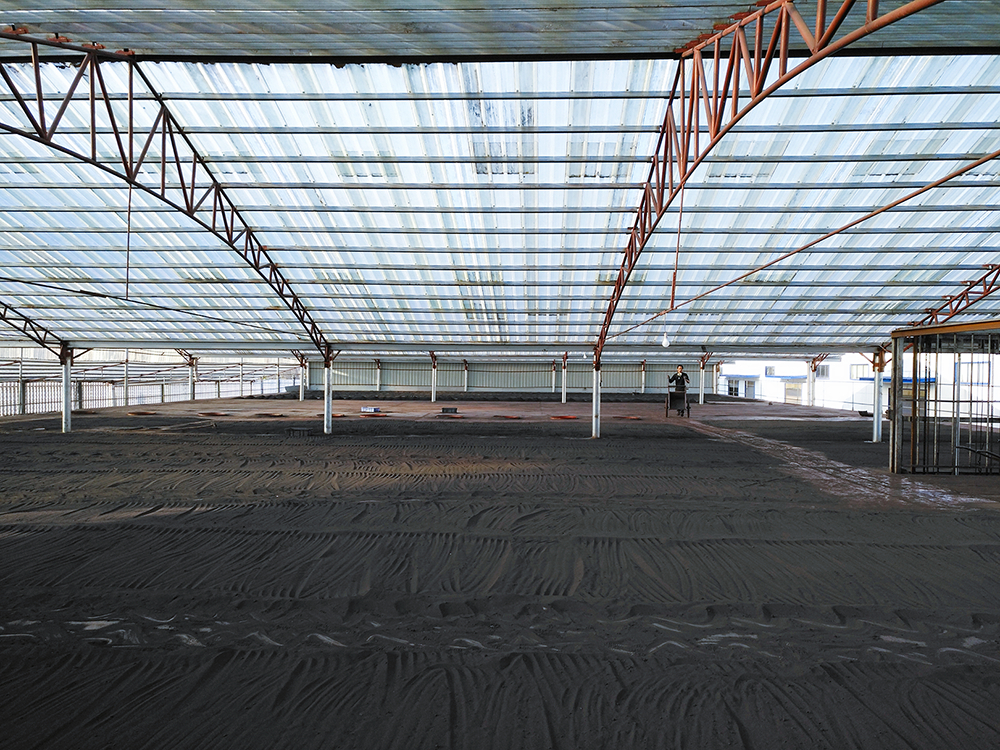

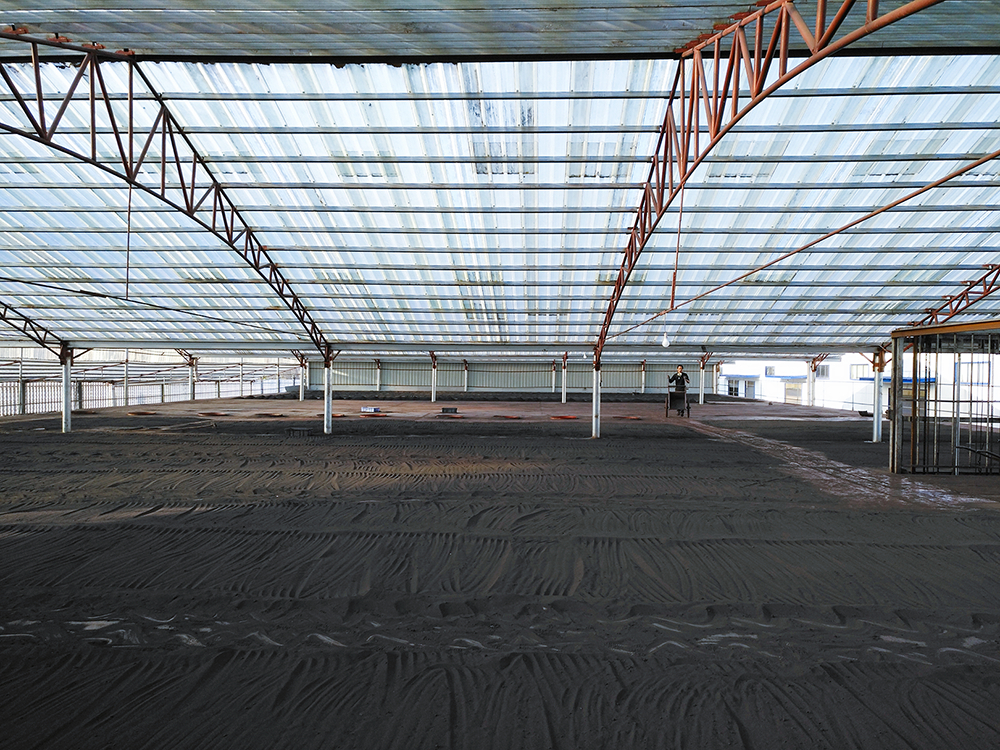

sintered area-ceramic magnet

3 year agoWhat is a ferrite magnet?

Ferrite magnets are more commonly referred to as ceramic magnets. They are obtained from iron oxides and from strontium or barium carbonate: these raw materials are generous on Earth, so availability of ferrite is rather high.

How to make ferrite permanent magnets?

The raw materials are mixed together, granulated and thermally treated to get finally hexaferrite phase (SrFe12O19 or BaFe12O19). This granulate is then ground to a powder.Pressing can be performed under magnetic field (anisotropic ferrite magnets) or not (isotropic ferrite magnets) and can be wet or dry.

What are the main characteristics for ferrite magnets?

Raw material is readily available and low in cost

Relatively brittle & hard

Easy to magnetize and good resistance to demagnetization

Excellent corrosion resistance

Good temperature stability

high coercive force and high electric resistance

Most widely used permanent magnets

Are surface treatments required for ferrite magnets(ceramic magnets)?

Ferrite Ceramic magnets do not need to be protected for surface rust. A thin film of magnet powder on the surface is common.

What grades & shapes are available for ferrite magnets?

Grades 5 (most commonly used) through 8 are available in disc, block (rectangle & square) and ring shapes, and can be custom manufactured to meet your specialty requirements.

What safety precautions should be taken into consideration when working with ceramic magnets?

Ferrite Magnets are hard ceramic materials in which solidified particles are densely combined.

However, ceramic magnet materials are inherently brittle and can be chipped and broken if dropped on the hard ground and rubbed each other.

It is recommended that they be not used for structural purpose since they are low in tensile and flexural strength.

What is a ferrite magnet?

Ferrite magnets are more commonly referred to as ceramic magnets. They are obtained from iron oxides and from strontium or barium carbonate: these raw materials are generous on Earth, so availability of ferrite is rather high.

How to make ferrite permanent magnets?

The raw materials are mixed together, granulated and thermally treated to get finally hexaferrite phase (SrFe12O19 or BaFe12O19). This granulate is then ground to a powder.Pressing can be performed under magnetic field (anisotropic ferrite magnets) or not (isotropic ferrite magnets) and can be wet or dry.

What are the main characteristics for ferrite magnets?

Raw material is readily available and low in cost

Relatively brittle & hard

Easy to magnetize and good resistance to demagnetization

Excellent corrosion resistance

Good temperature stability

high coercive force and high electric resistance

Most widely used permanent magnets

Are surface treatments required for ferrite magnets(ceramic magnets)?

Ferrite Ceramic magnets do not need to be protected for surface rust. A thin film of magnet powder on the surface is common.

What grades & shapes are available for ferrite magnets?

Grades 5 (most commonly used) through 8 are available in disc, block (rectangle & square) and ring shapes, and can be custom manufactured to meet your specialty requirements.

What safety precautions should be taken into consideration when working with ceramic magnets?

Ferrite Magnets are hard ceramic materials in which solidified particles are densely combined.

However, ceramic magnet materials are inherently brittle and can be chipped and broken if dropped on the hard ground and rubbed each other.

It is recommended that they be not used for structural purpose since they are low in tensile and flexural strength.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- HU NAN YUBANG MAGNETIC MATERIAL CO.,LTD

- *Message:

-

Submit

Main Product:

Permanent Ferrite Magnets,

Isotropic Ferrite Magnets,

Anisotropic Ferrite Magnets ,

Anisotropic Ferrite Magnet Rotor,

Isotropic Multipole Magnetic Rotor,

Sintered Neodymium Magnets

You May Also Like