Automatic Paper Carton Erecting Forming Machine

2 year ago

|

Type |

BC-B carton box erecting forming machine |

|

Suitable material |

200-600gsm white card board, PE coated paper, Kraft paper, corrugated paper |

|

Production speed |

50-120pcs/min |

|

Blank paper size |

Length 100-480mm, Width 100-630mm, Height 15-200mm, Angle 4-50° |

|

Blank paper weight |

Max. 3mm for corrugated paper |

|

Total power |

5.5KW |

|

Total weight |

2200KGS |

|

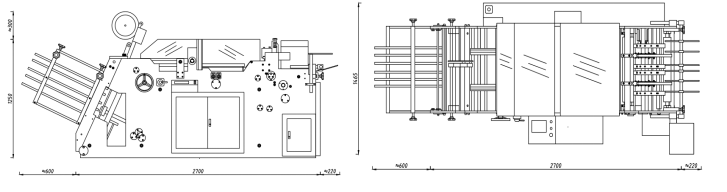

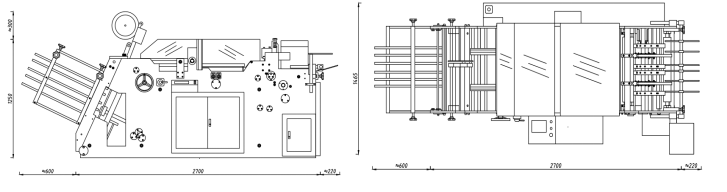

Overall dimension |

3520*1465*1550mm |

|

Packing dimension |

3560x1510x1690mm |

|

Power source |

380V, 50HZ |

|

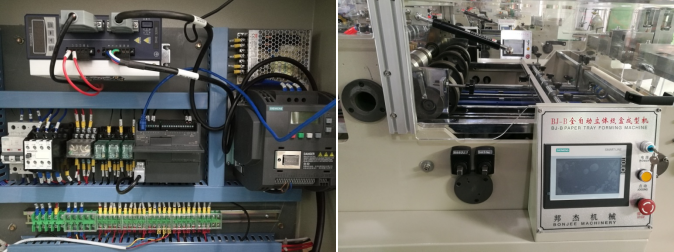

MAIN ELECTRICAL PARTS LIST: (BRAND) |

|

|

1) Frequency converter |

Siemens, German |

|

2) Programmable controller |

Siemens, German |

|

3) PLC power |

Siemens, German |

|

4) Touch panel |

Siemens, German |

|

5) Photo electronic switch |

Autonics, Korea |

|

6) A.C contactor |

Siemens, German |

|

7) Button |

Siemens, German |

|

8) Reply |

Siemens, German |

Machine brief details:

1). It is an ideal equipment to produce paper box such like hamburger box, chips box, fried chicken box, kids meal box, fast food box, fast noodles box etc.

2). With firm structure, high quality, low noise and high efficiency.

3). It has paper feeding unit, adjusted unit, glue unit, forming unit, finished products collecting unit and also counting unit.

Main differences and advantages:

1.With very experienced engineers and designer, we never stop, keep improving and perfecting on machines. We can custom order and put plasma device, hot melt glue device on the machine as customer required.We were the first factory in China who choosing servo motor for feeding paper system instead of traditional cam system, it have less noise and easier to adjust in order to make different size and shape boxes.

In the year of 2014, we have applied to Patents and the number as below.

(For paper feeding system –servo motor device)

2). Driving system: swinging arm get improving, it works more steady and service for a longer time.

3). We improved and use bigger and heavier gear sleeve instead of usual small gear sleeves, help in machine running more stable.

4). All the gears have been second processed by gear grinding machine, in order to make it smooth, then go quenching treatment. For those parts we pay extra processing money because we want it to be perfect quality.

6). Auto counting and collecting system.

7). PLC and Touch screen.

Available box can be made by our BC-B box forming machine

Width: 100-580mm

Height: 15-200mm

Degree: 50-400

Paper weight: 200-600g/m2

Paper thickness: 3mm max

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Anhui Innovo Bochen Machinery Manufacturing Co., Ltd.

- *Message:

-

Submit

Main Product:

flute laminating machine,

pile turner ,

litho laminating machine,

gift box making machine,

book case making machine,

flip flop machine

You May Also Like