semi-embossing for simple printing

2 year ago

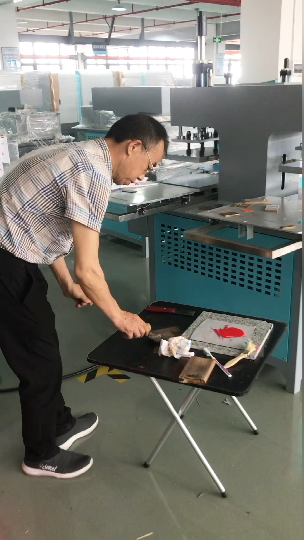

Silicone Heat Press Logo For Mat Pad

Silicone heat press printer is an embossing machine, also known as silicone machine. The embossing machine is mainly used to emboss, foam, wrinkle and label on various fabrics. It can also emboss trademarks, simulated leather patterns and various shades on Mats, Pad, Non-woven fabrics, coatings, Leather, Paper and aluminum plates,flower types and patterns.

Core advantages of embossing machine:1.Intelligent PID output temperature control, the temperature difference is plus or minus 5 degrees, which is more economical and prower-saving.

2.With preheating function.

3.The embossing machine has two working positions, which can work simultaneously or be controlled independently.

The embossing machine is easy to operate, increases output and saves manpower.

| Name | Jinyu Semi-auto Embossing Machine |

| Model | JY-B04 |

| Voltage | 380V/50Hz |

| Station | 2 |

| Wore area | 300*400mm |

| Motor power | 2.2kw |

| Maximum temp | 400℃ |

| Total Power | 13kw |

| Maximum pressure | 1.2 |

| Pump maximum utput pressune | 70 |

| Size | 1600*1550*1700mm |

| Weight | 500kg |

2. Preparation for the embossing machine: The embossing machine is powered on. The heating temperature is generally set between 170-240 degrees according to the size of the mold and the amount of glue. The hot pressing time is also adjusted according to the size and thickness of the product. Generally, clothing the small LOGO on the pocket can be set to 12-30 seconds;

Freezing station: The temperature can be set within the range of 0-10 degrees.

3. Silicone material preparation: Add color paste and a certain proportion of curing agent to silicone, stir evenly, and send it to the vacuum table for defoaming treatment.

4. Fabric preparation: Non-woven fabrics or relatively high-temperature resistant fabrics can be glued. Nylon fabrics will deform. Lay the prepared fabric flat on the sliding table of the embossing machine.

5. Squeegee: Hold the mold in one hand, and hold the scraper in the other. Fill the vacuumed silicone into the mold, scrape it evenly and then send it to the vacuum table to defoam the glue on the mold.

6. Remove excess glue: The glue on the surface of the mold after defoaming must be scraped off with a silicone plate to ensure that there is no glue on the flat surface of the mold before proceeding to the next step.

7. Glue planting: Put the processed and glue-filled mold into the designated position on the cloth, send it to the embossing machine, and heat and pressurize it to shape.

At this point, the glue planting process is completed. Separate the mold from the fabric, and place the mold on the freezing table for rapid cooling. When the temperature of the mold drops to about 40 degrees, the next round of glue application---defoaming-- can be carried out. Scraping mold---forming....... cycle!

Dongguan Jinyu Automation Equipment Co., Ltd are specialized in the development and manufacturing of PVC label machine, Silicone Trademark Machine, Garments Printing machine, silicone vulcanizing hydraulic machine , silicone injection molding machine, silicone heat transfer lable machine, silicone patch dispensing machine, ect.

With more than 20 years of independent research and development, we have a senior and specialized group. Our company have set up a good reputation within the industry and become the earliest production base of PVC products making machine, silicone products making machine and other related machines all over the world.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Dongguan Jinyu Automation Equipment Co., Ltd.

- *Message:

-

Submit

Main Product:

Dispensing Machines,

PVC Machines,

Silicone Machines ,

Kpu Shoes Machines,

Silicone Label Embossing Machines,

Hydraulic Machines