Sintered round ceramic ferrite magnet

2 year ago

What's Arc Ferrite Magnet?

Arc ferrite magnets, also known as ferrite arc magnets or ceramic arc magnets, are a type of permanent magnet made from a combination of iron oxide and strontium carbonate or barium carbonate. They belong to the family of ceramic magnets and are known for their high coercivity and low cost.

Arc ferrite magnets are typically manufactured in a curved or arc shape, allowing them to be used in various applications that require a specific magnetic field configuration. They are commonly used in motors, generators, loudspeakers, magnetic separators, magnetic resonance imaging (MRI) machines, and other devices where a strong magnetic field is needed.

These magnets have a relatively low magnetic energy product compared to other types of magnets, such as neodymium magnets. However, they have excellent resistance to corrosion and can operate at high temperatures, making them suitable for environments where other magnets may not be suitable.

Arc ferrite magnets are cost-effective and widely available, making them a popular choice in many industries. However, they have lower magnetic strength compared to some other types of magnets, which may limit their use in certain applications that require stronger magnetic fields.

The production of Barium Ferrite Magnets?

Barium ferrite magnets, also known as ceramic magnets or ferrite magnets, are a type of permanent magnet made from a combination of barium and iron oxide. These magnets are widely used in various applications such as motors, speakers, magnetic separators, and magnetic resonance imaging (MRI) machines.

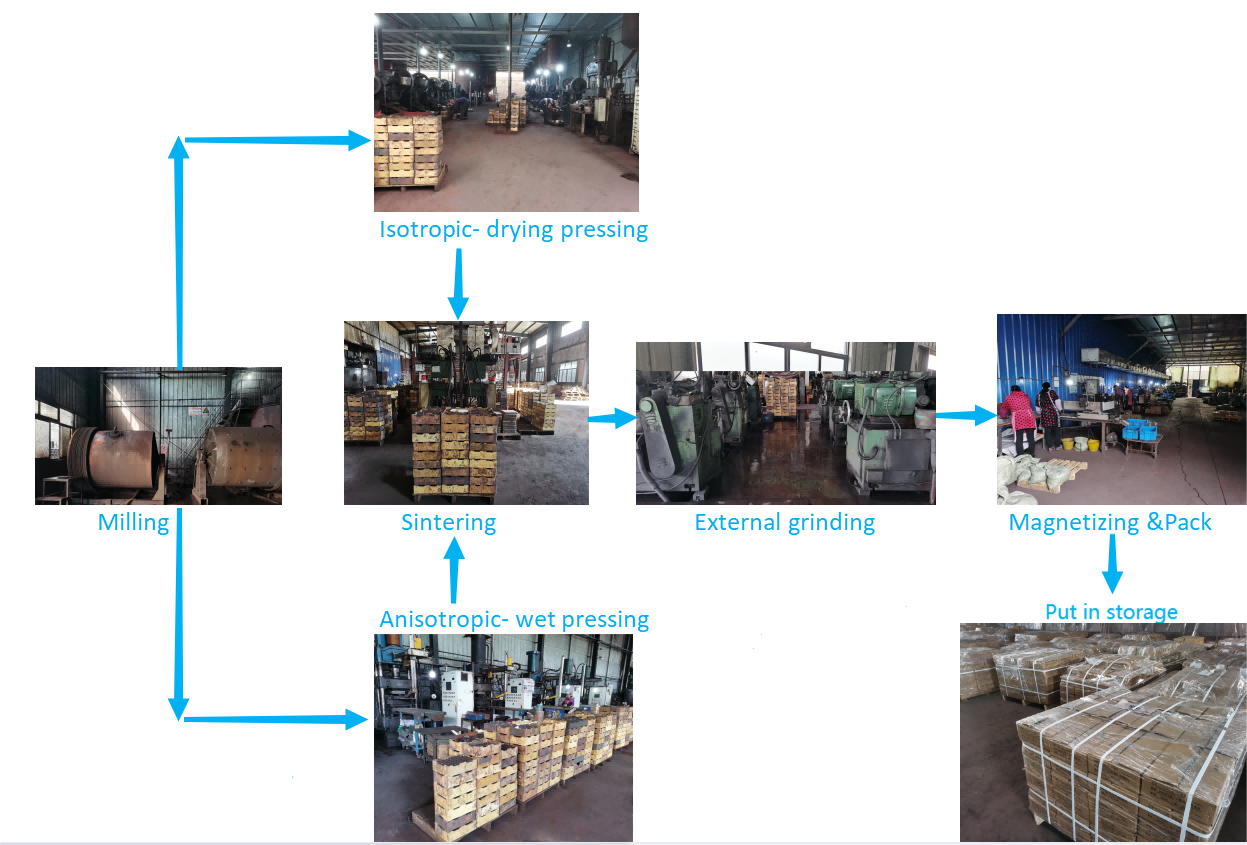

The production process of barium ferrite magnets involves several steps:

1. Raw material preparation: The key ingredients for barium ferrite magnets are barium carbonate (BaCO3) and iron oxide (Fe2O3). These materials are carefully selected and measured to ensure the desired magnetic properties.

2. Mixing: The barium carbonate and iron oxide powders are mixed together in a specific ratio. Other additives such as binders and fluxing agents may also be added to improve the magnet's properties and processability.

3. Grinding: The mixture is then ground into a fine powder using ball mills or other grinding equipment. This step helps to achieve a homogeneous and consistent particle size distribution.

4. Forming: The powdered mixture is pressed into the desired shape using a hydraulic press or an extrusion process. The pressing is done under high pressure to compact the powder and remove any air voids.

5. Sintering: The formed magnets are then sintered in a high-temperature furnace. Sintering involves heating the magnets to temperatures above their melting point but below the melting point of the barium ferrite compound. This process helps to fuse the particles together and create a solid magnet with improved magnetic properties.

6. Machining and finishing: After sintering, the magnets are machined to achieve the final dimensions and shape. Various cutting, grinding, and polishing techniques may be used to obtain the desired surface finish.

7. Magnetization: The magnets are then magnetized by subjecting them to a strong magnetic field. This process aligns the magnetic domains within the material, making it magnetic.

8. Quality control: Throughout the production process, quality control measures are implemented to ensure the magnets meet the required specifications. This includes testing the magnetic properties, such as magnetic field strength and coercivity, as well as checking for any defects or imperfections.

Overall, the production of barium ferrite magnets involves a combination of chemical reactions, powder processing, high-temperature treatment, and precision machining to achieve the desired magnetic properties and final product.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- HU NAN YUBANG MAGNETIC MATERIAL CO.,LTD

- *Message:

-

Submit

Main Product:

Permanent Ferrite Magnets,

Isotropic Ferrite Magnets,

Anisotropic Ferrite Magnets,

Anisotropic Ferrite Magnet Rotor ,

Isotropic Multipole Magnetic Rotor,

Sintered Neodymium Magnets