small arc finish in metal panel forming equipment

2 year agoThe AG1000 is a compact and versatile press brake center designed for small-scale manufacturing. With its suction cup type design, the AG1000 is capable of

clamping plates of different materials and thicknesses, making it a convenient and reliable option for various applications.

Technical Parameters & Specification:

Model

Unit

AG-1000

Bending Length

mm

1000

Plate Length

mm

1100

Plate Width

mm

1000

Bending Height

mm

175/200

Min Forming Size(Four sides)

mm

300*200

Min Forming Size(One side)

mm

200

Min Radius

mm

1.2

Bending Speed

s

0.5/bend

Opening Height

mm

180

Angle

°

0-180°

Material Thickness

mm

aluminum:2.0

carbon steel :1.5

stainless steel:1.2

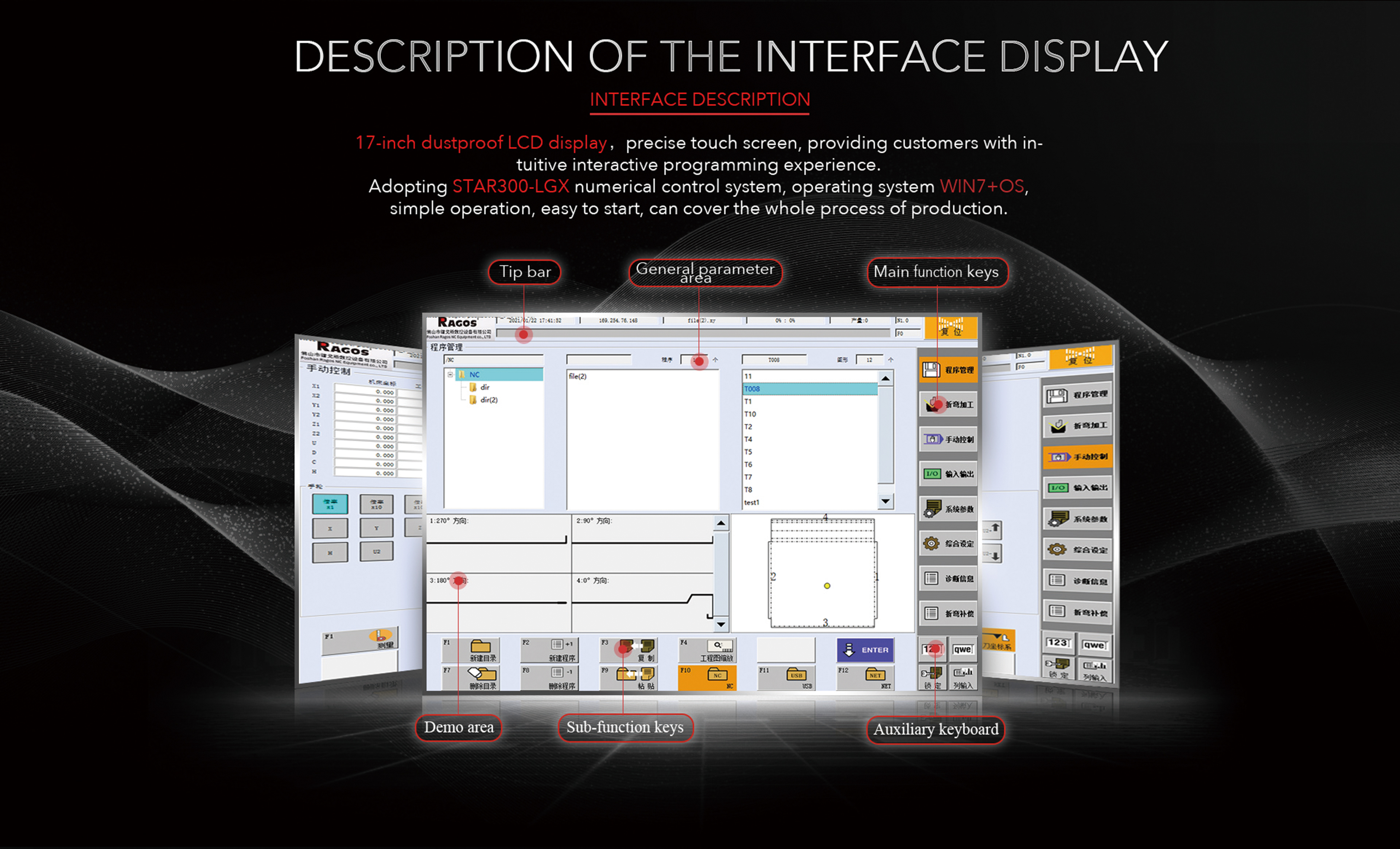

Numerical System

Star300-LGx

Operating System

OS

RT-Linux

Axis

axes

Normal: 8

Machine Dimension

Length

mm

2900

Width

mm

1390

Height

mm

2600

Machine Weight

kg

6000

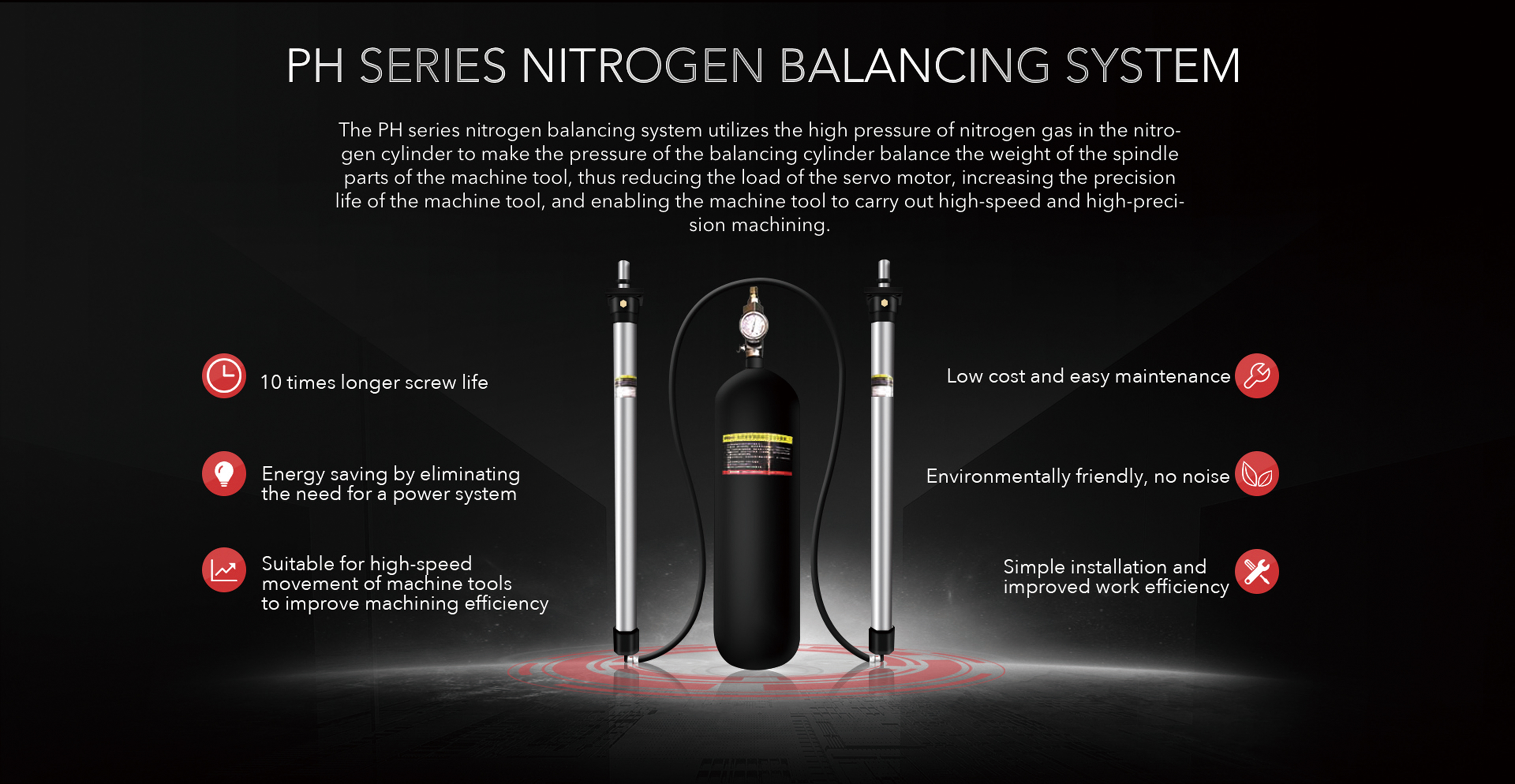

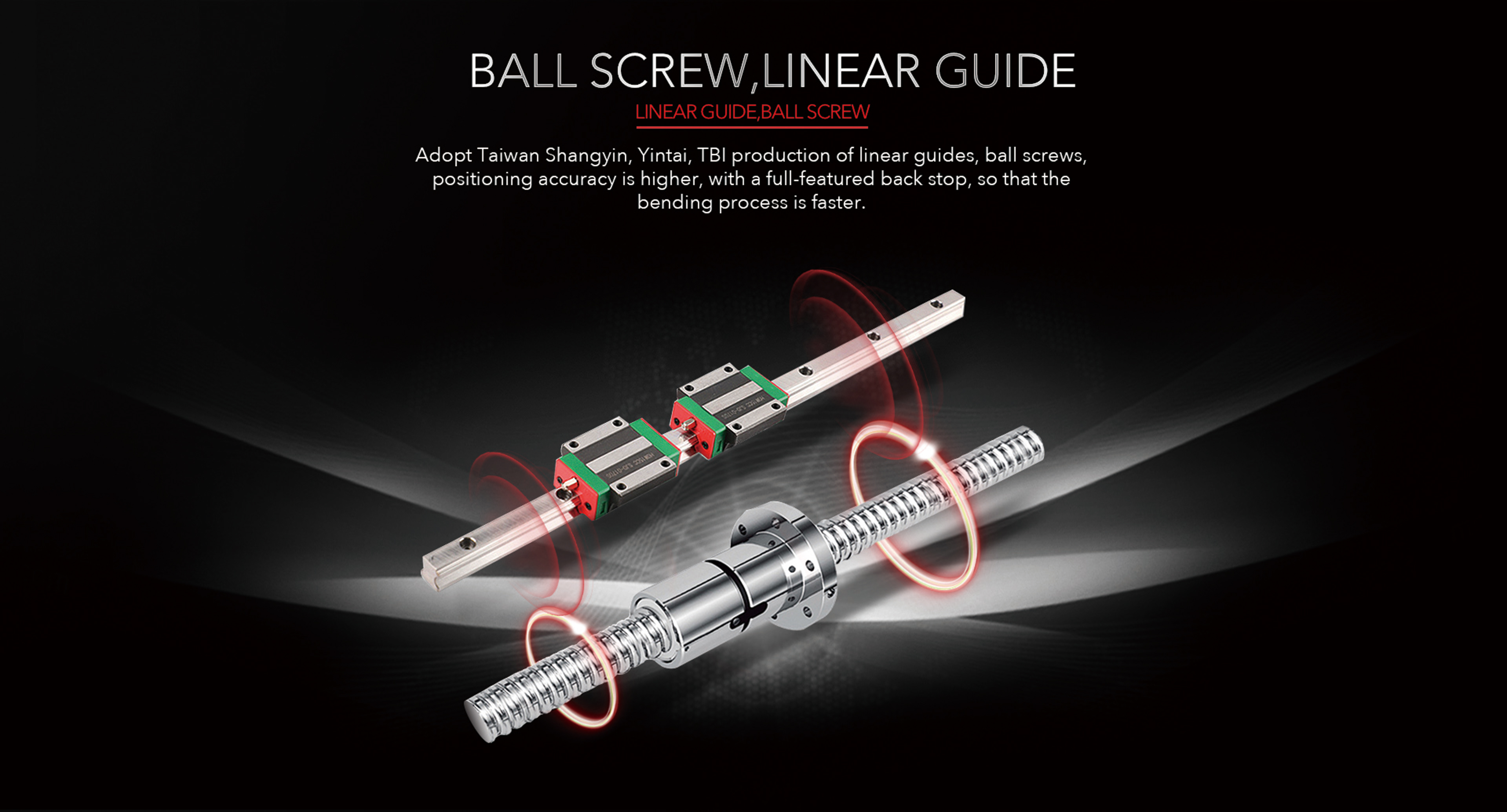

The AG1000 Panel Bender features a high-precision servo motor that drives a precision ball screw to achieve stable and reliable feeding accuracy.

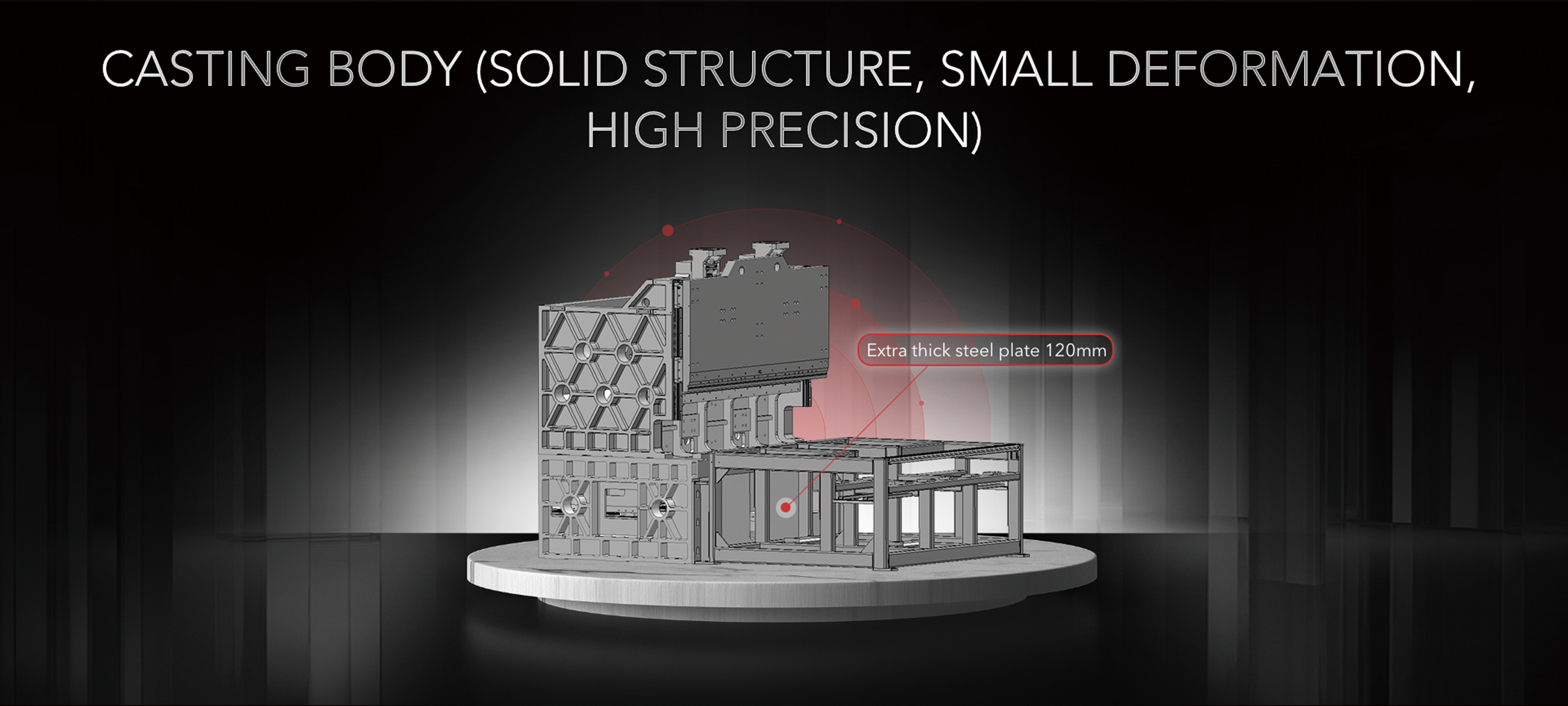

The machine's frame is designed using finite element analysis, resulting in a moderate lightweight that achieves the balance between rigidity and high efficiency.

The suction cup type clamping system of the AG1000 provides a reliable and convenient way to clamp plates of different materials and thicknesses.

The suction cups are easy to adjust and can be replaced quickly, making the AG1000 Automatic Panel Bender a versatile option for various applications.

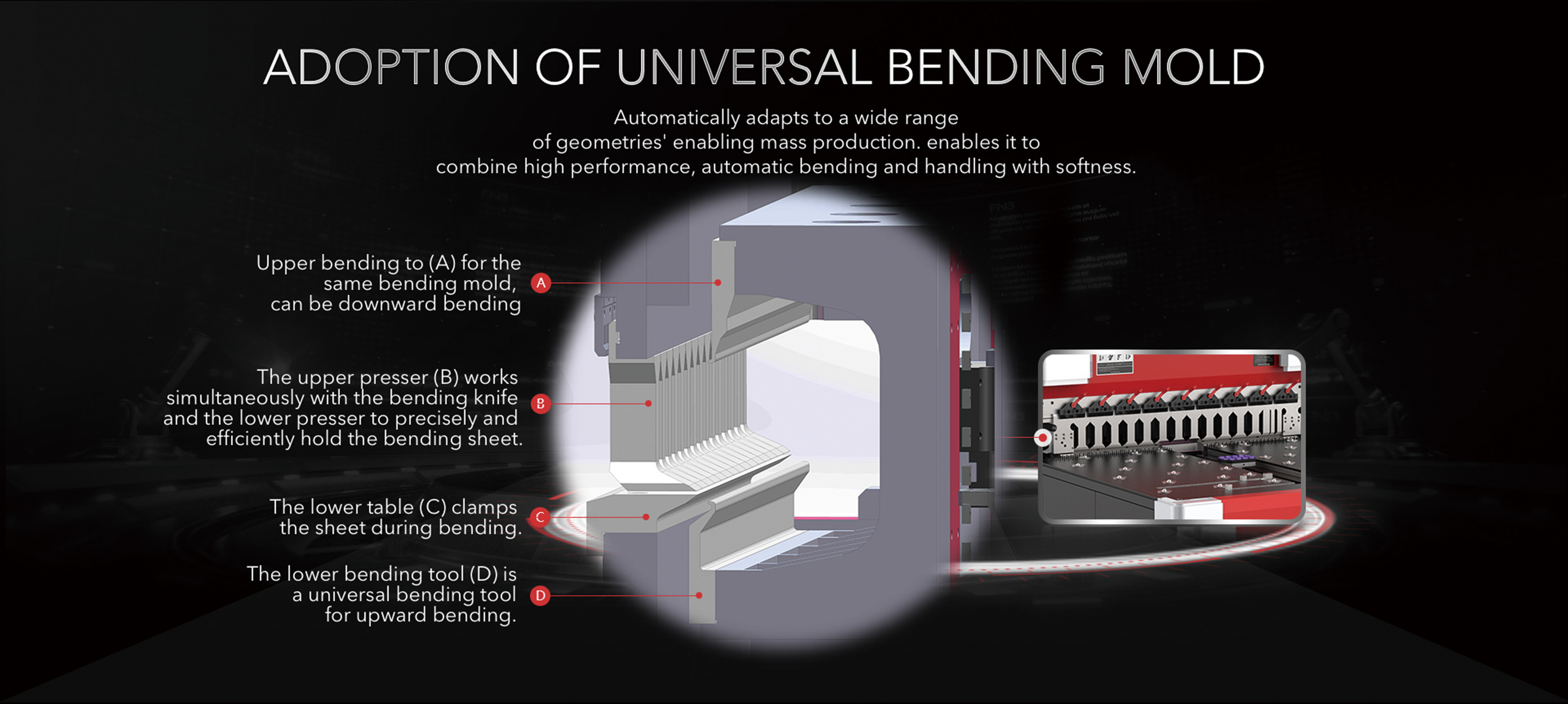

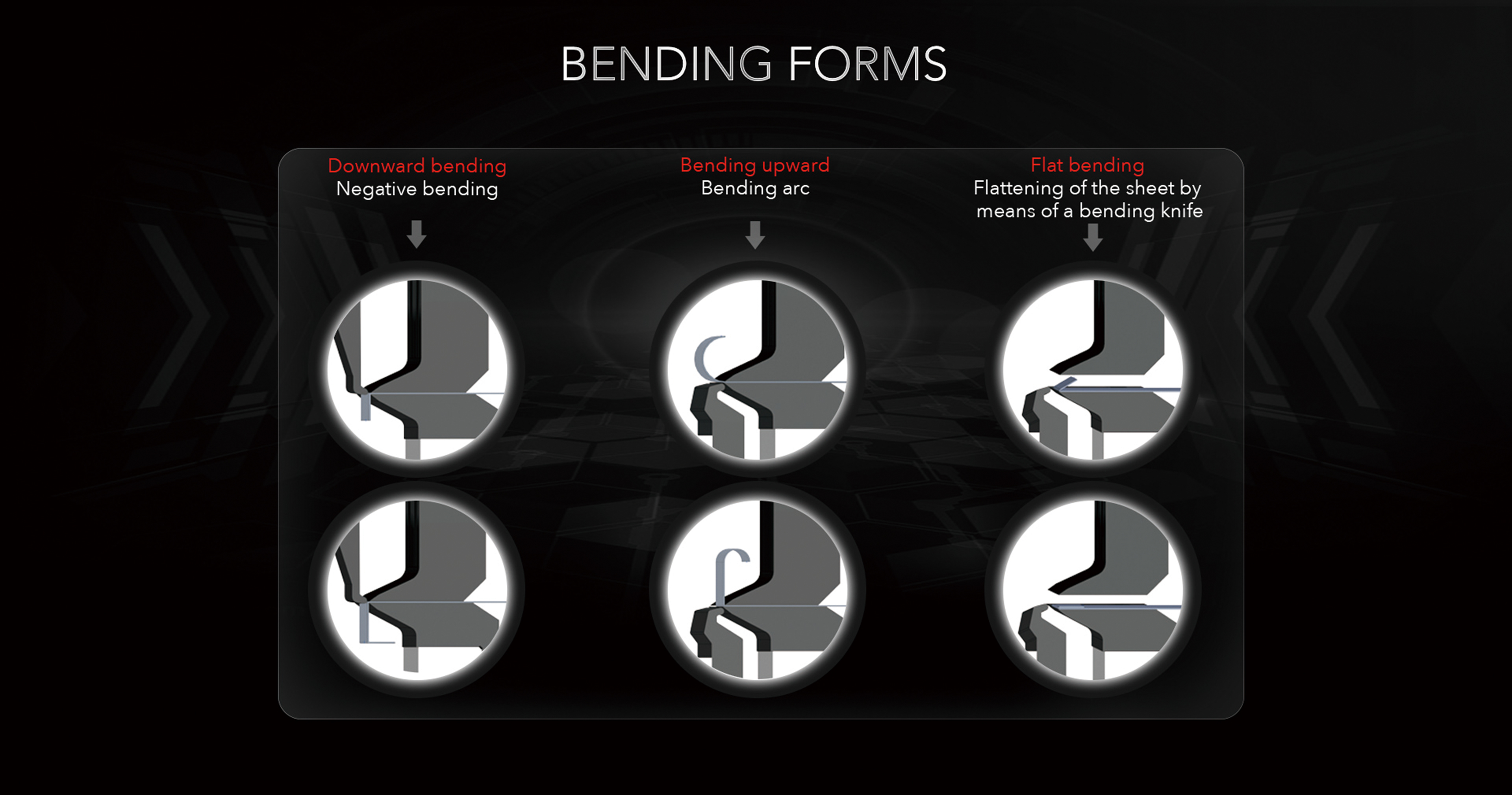

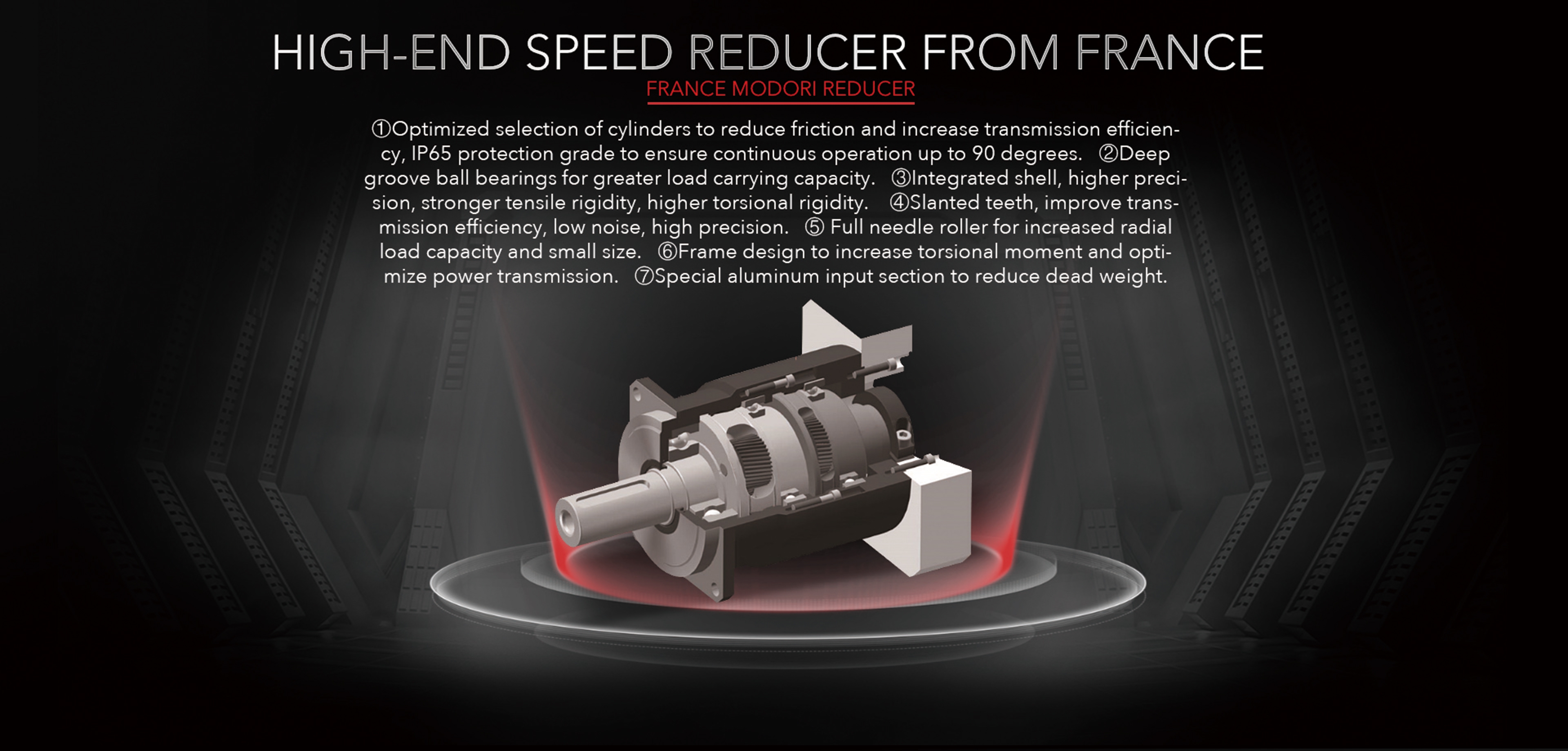

The AG1000 Bending Machines also features a mechanical servo bending system that provides high transmission rigidity and precision.

The stroke and speed of the servo folding beam can be adjusted according to processing requirements, allowing for higher efficiency and better folding quality.

The AG1000 comes equipped with a standard worktable that uses composite steel balls and brush surfaces to reduce resistance and surface damage.

The tilting table design also makes maintenance more convenient.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- FOSHAN RAGOS NC EQUIPMENT CO.,LTD.

- *Message:

-

Submit

Main Product:

Panel Bender,

Full electric servo press brake,

Press Brake Machines,

Down acting hybrid cnc press brake,

Dual servo hybrid cnc press brake ,

Up-acting hybrid cnc press brake