12x18 ferrite magnet rotor-long neck

2 year agoWhat's Water Pump Rotor Magnet?

A ferrite magnet rotor refers to a type of rotor used in electric motors or generators. It is made of a magnetic material called ferrite, which is a type of ceramic material composed of iron oxide and other metal oxides. Ferrite magnets are known for their high coercivity, meaning they have a strong resistance to demagnetization. This makes them suitable for use in various applications, including electric motors, where they provide a strong magnetic field for efficient operation. The ferrite magnet rotor is the rotating component of the motor or generator that generates the magnetic field necessary for the conversion of electrical energy to mechanical energy or vice versa.

The production of Ferrite Magnet Rotor?

The production of Ferrite Magnet Rotor involves several steps:

1. Material selection: The first step is to select the appropriate ferrite material for the magnet rotor. Ferrite magnets are made from a combination of iron oxide and other metallic elements such as strontium or barium.

2. Mixing: The selected ferrite material is mixed with a binder material, typically a polymer, to form a slurry. This slurry is mixed thoroughly to ensure a uniform distribution of the magnetic particles.

3. Molding: The slurry is then poured into a mold that has the desired shape and dimensions of the magnet rotor. The mold is typically made of steel or other materials that can withstand high temperatures and pressures.

4. Pressing: The slurry-filled mold is subjected to high pressure to compact the mixture and remove any air bubbles. This step helps to increase the density and strength of the magnet.

5. Sintering: The compacted mold is then heated to a high temperature in a controlled atmosphere. This process, known as sintering, helps to fuse the magnetic particles together and create a solid magnet.

6. Machining: After sintering, the magnet rotor is machined to achieve the desired dimensions and surface finish. This may involve cutting, grinding, and polishing the magnet to remove any excess material and achieve the required tolerances.

7. Magnetization: The final step is to magnetize the rotor. This is done by subjecting the magnet to a strong magnetic field, either by using an electromagnet or by passing a current through the rotor. This aligns the magnetic domains within the material and gives the rotor its magnetic properties.

Once the production process is complete, the ferrite magnet rotor can be used in various applications such as electric motors, generators, and magnetic separators.

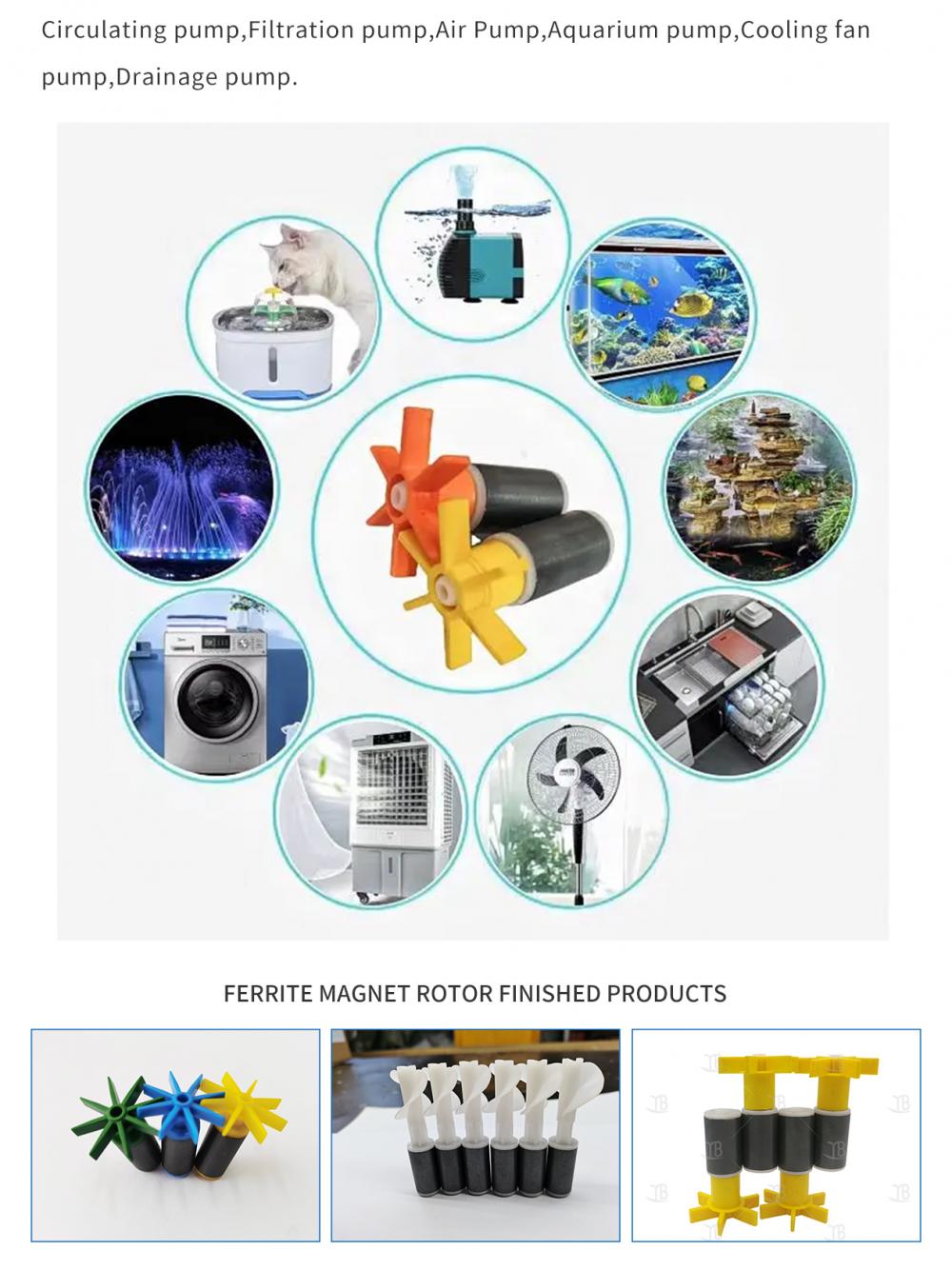

The application of Anisotropic Ferrite Magnet Rotor

Other related products:

Anisotropic Cylinder Ferrite Magnets, Isotropic Ferrite Magnets, Ferrite Permanent Magnets, Multipole Ferrite Ring Magnet,Sintered Neodymium Magnet, Teaching Ferrite Magnet

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- HU NAN YUBANG MAGNETIC MATERIAL CO.,LTD

- *Message:

-

Submit

Main Product:

Permanent Ferrite Magnets ,

Isotropic Ferrite Magnets,

Anisotropic Ferrite Magnets,

Anisotropic Ferrite Magnet Rotor,

Isotropic Multipole Magnetic Rotor,

Sintered Neodymium Magnets