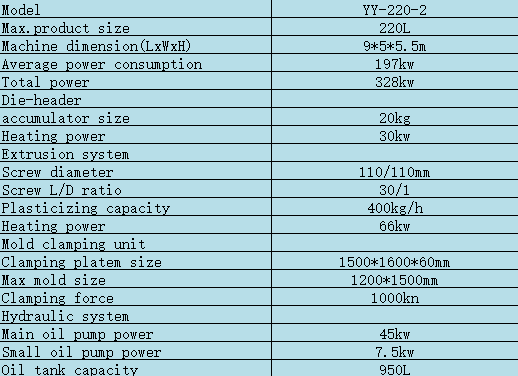

220l blue barrel chemical drum making machine

2 year agoThis is a 55-gallon chemical barrel filling machine that can produce double-layer products. The factors that affect production and product quality are mainly temperature, melt, pressure, and melt flow speed. Temperature has a significant effect on the performance of plastic extrusion and preforms. Increasing the temperature of the extruder can reduce the viscosity of the melt, improve the fluidity of the melt, reduce the power consumption of extrusion, and increase the screw speed without affecting the mixing and plasticizing effect of the plastic, which is beneficial to improving the strength and finish of the product. The influence of melt pressure High melt pressure promotes good plasticization and uniform coloring of the mixture, especially for high-density polyethylene and low-density polyethylene blends, and coloring reverse fields. The crystal points and cloud-like patterns on the preform are reduced. Generally, the melt pressure is increased by increasing the screw speed. Melt delivery rate The greater the melt delivery rate and the higher the extruder output, increasing the screw diameter and increasing the extruder temperature can increase the melt delivery rate.Blow Molding Machine.Blow Molding Molds.Water Tank Blow Molding Machine

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Weifang Yuyang plastic machinery co,.ltd,

- *Message:

-

Submit

Main Product:

Blow Molding Machine ,

Blow Molding Molds,

Water Tank Blow Molding Machine,

55 gallon Blow Molding Machine,

IBC tank Blow Molding Machine,

YuyangIknow

You May Also Like