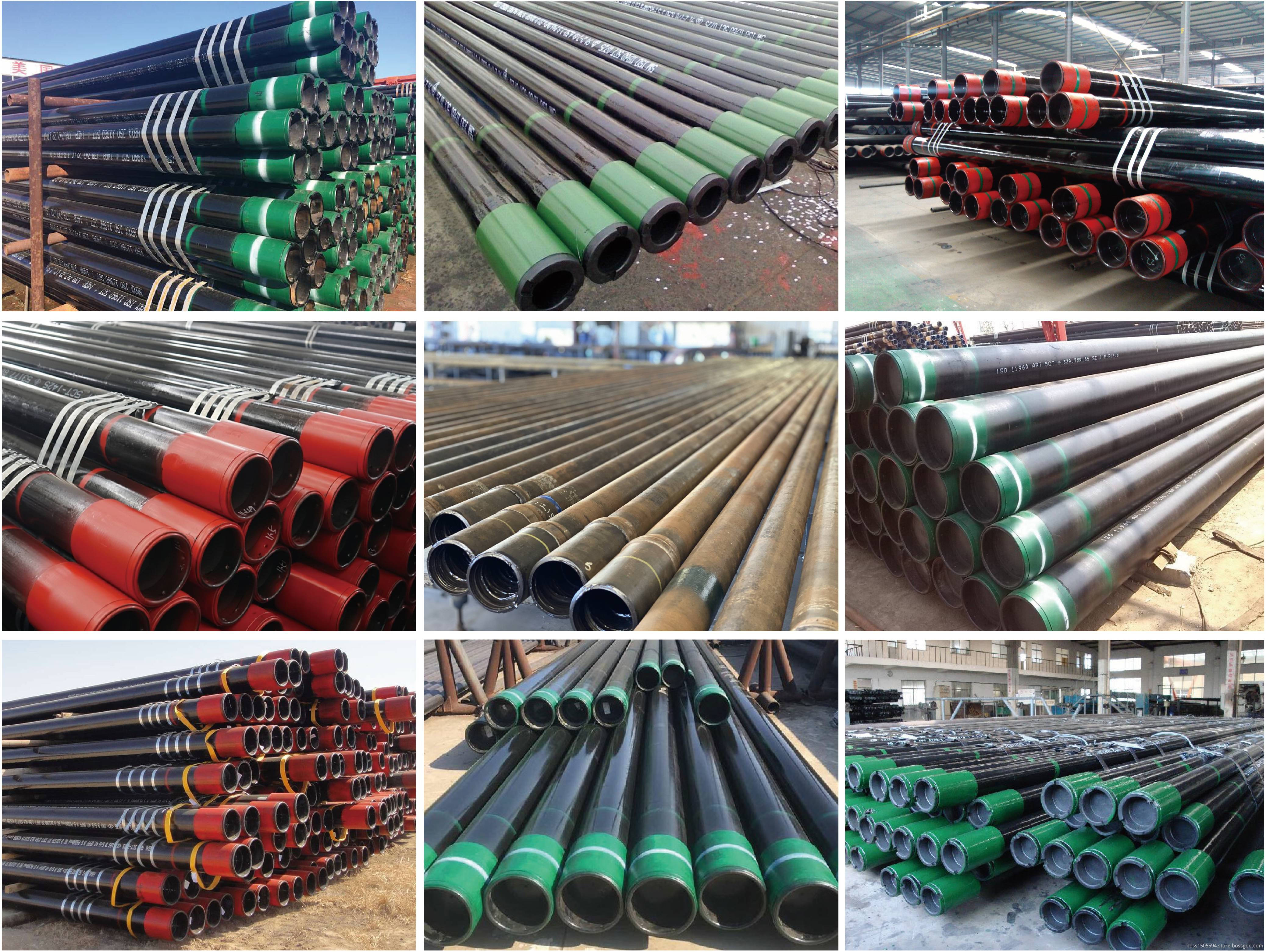

API-5CT Oil Casing Pipe (4)

12 month ago

The oil casing is a steel tube used to support the well wall of oil and gas Wells to ensure the normal operation of the whole well during the drilling process and after completion. Several layers of casing are used for each well, depending on the drilling depth and geology. Cement is used for cementing after casing well. Unlike tubing and drill pipe, cement can not be reused and belongs to disposable consumption material. As a result, casing consumption accounts for more than 70% of all well tubing.

Casing can be divided into: conduit, surface casing, technical casing and reservoir casing.

Special petroleum pipe is mainly used for drilling oil and gas Wells and oil and gas transportation. It includes oil drilling pipe, oil casing, extraction pipe. The oil drill pipe is used to connect the drill collar to the drill bit and transfer drilling power. The oil casing is mainly used to support the well wall during drilling and after completion to ensure the drilling process and the normal operation of the whole oil well after completion. The suction pipe mainly conveys oil and gas from the bottom of the well to the surface.

The oil casing is the lifeline to maintain the operation of oil well. Due to the different geological conditions, the downhole stress state is complex, and the comprehensive effect of tension, pressure, bending and torsion stress on the pipe body has put forward a higher demand on the quality of the casing itself. If the casing itself is damaged for some reason, it can lead to production loss or even abandonment of the entire well.

According to the strength of steel itself, casing can be divided into different steel grades, namely J55, K55, N80, L80, C90, T95, P110, Q125, V150, etc. Well conditions, different depths, the use of steel grade is also different. In corrosive environment, the casing itself is required to have corrosion resistance. In the complex geological conditions, it is also required that the casing has anti-collapse performance.

The pipe is inserted into the hole and fixed with cement to help separate the wellbore from rock formations and prevent collapse, while also allowing drilling mud to circulate to facilitate drilling. Casing end processing type: short round thread, long round thread, partial trapezoidal thread, special buckle, etc. It is mainly used to support the well wall during drilling and after completion to ensure the drilling process and the normal operation of the whole well after completion. Different types of casing used in oil extraction: The surface casing protects the well from shallow water and gas, supports the wellhead equipment, and maintains the weight of other layers of the casing. The technical casing separates the pressures at different levels to allow the flow of drilling fluid and protect the production casing. In order to install blowout preventers, leak preventers and liner in the well. Oil reservoir The oil casing extracts oil and gas from reservoirs below the surface. Used to protect drilling and to layer drilling mud. Casing sizes range from 114.3 mm to 508 mm.

Protects the well from shallow water and gas contamination, supports the wellhead equipment and maintains the weight of other layers of the casing:

The technical casing separates the pressures at different levels to allow the flow of drilling fluid and protect the production casing. In order to install blowout preventers, leak preventers and liner in the well.

Reservoir Casing - To drain oil and gas from reservoirs below the surface. Used to protect drilling and to layer drilling mud. Casing sizes range from 114.3 mm to 508 mm.

The types and packing of petroleum casing are divided into short thread casing and its coupling and long thread casing and its coupling according to SY/T6194-96" petroleum casing ".

Drill pipe is a type of steel pipe with screw bars at the end that is used to connect the rig's surface equipment to the drilling and grinding equipment or bottom hole unit located at the bottom of the drill. The drill pipe is used to transport drilling mud to the drill bit, and with the drill bit to raise, lower, or rotate the bottom hole device. Drill pipe must be able to withstand tremendous internal and external pressure, distortion, bending and vibration. Drill pipe can be used multiple times during oil and gas extraction and refining.

The light pipe and raw steel pipe are made into drill pipe after several processing steps. First, through the processing of steel pipe thickening process, the surface of the light pipe is inward bent, and the steel pipe wall is thickened. Next, threads are threaded and copper plated to increase strength. This is followed by a non-destructive quality control inspection followed by welding of the pipe body joint. The tube is then subjected to welding heat treatment and welding final treatment to eliminate welding residual pressure. Other tests, including hardness tests, pressure tests and non-destructive tests, should be carried out on finished pipe before finished pipe is painted and packaged.

The length of drill pipe is usually about nine meters.

|

Product Name |

API 5CT Oil Casing Pipe |

|

|

Standard |

API 5CT, ASTM A106, A53 Gr.B, ANSI A210-1996, ANSI B36.10M-2004, ASTM A1020-2002, ASTM A179-1990, BS 3059-2, DIN 17175, DIN 1630, DIN 2448 |

|

|

Steel Grade |

H40, J55, K55, M65, N80, L80, C90, C95, T95, C110, P110, Q125, GR.A, GR.B, GR.C, ST35, ST37, ST42, ST45, ST52, SS304, SS316 etc. |

|

|

Size |

Outer Diameter |

114.30mm -508.00mm |

|

Wall Thickness |

5.21mm-16.13mm |

|

|

Length |

R1:4.88-7.62m; R2:7.62-10.36m; R3:10.36-12.80m; Less than 12m, or as buyer's requirements |

|

|

Certificates |

API5CT, ISO 9001: 2015 |

|

|

Surface Treatment |

black paint, varnish, oil, galvanized, anti corrosion coatings |

|

|

Marking |

Standard marking, or according to your request. |

|

|

Pipe Ends |

Under 2 inch plain end. 2 inch and above Beveled. Plastic caps (small OD) ,Iron protector (large OD) |

|

|

Packaging |

Loose package; Packaged in bundles(2Ton Max); bundled pipes with two slings at the both end for easy loading and discharging; End with Plastic caps; Wooden cases.Or as buyer’s requirements. |

|

|

Test |

Chemical Component Analysis, Mechanical Properties, Technical Properties, Exterior Size Inspection, hydraulic testing, X-ray Test. |

|

|

Application |

oil pipe; gas pipe; water pipe; sewage Transport |

|

|

Advantages |

1.Reasonable price with excellent quality 2.Abundant stock and prompt delivery 3.Rich supply and export experience, sincere service 4.Reliable forwarder, 2-hour away from port. |

|

|

Port of Shipment |

Tianjin Port, China |

|

|

Date of Delivery |

Shipped in 10 days after payment |

|

Mechanical property:

|

Standard |

Model number |

Tensile strength (MPa) |

Yield strength (MPa) |

Durometer |

|

API SPEC 5CT |

J55 |

≥517 |

379~552 |

|

|

K55 |

≥517 |

≥655 |

|

|

|

N80 |

≥689 |

552~758 |

|

|

|

L80(13Cr) |

≥655 |

552~655 |

≤241HB |

|

|

P110 |

≥862 |

758~965 |

|

Chemical composition:

|

Standard |

Model number |

Chemical composition (%) |

||||||||||

|

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Cu |

Mo |

V |

Als |

||

|

API SPEC 5CT |

J55K55 (37Mn5) |

0.34~0.39 |

0.20~0.35 |

1.25~1.50 |

≤0.020 |

≤0.015 |

≤0.15 |

≤0.20 |

≤0.20 |

/ |

/ |

≤0.020 |

|

N80 (36 Mn2V) |

0.34~0.38 |

0.20~0.35 |

1.45~1.70 |

≤0.020 |

≤0.015 |

≤0.15 |

/ |

/ |

/ |

0.11~0.16 |

≤0.020 |

|

|

L80(13Cr) |

0.15~0.22 |

≤1.00 |

0.25~1.00 |

≤0.020 |

≤0.010 |

12.0~14.0 |

≤0.20 |

≤0.20 |

/ |

/ |

≤0.020 |

|

|

P110 (30CrMo) |

0.26~0.35 |

0.17~0.37 |

0.40~0.70 |

≤0.020 |

≤0.010 |

0.80~1.10 |

≤0.20 |

≤0.20 |

0.15~0.25 |

≤0.08 |

≤0.020 |

|

Length range:

|

lengths |

|||

|

project |

range 1 |

range 2 |

range 3 |

|

oil pipe |

6.10-7.32m |

8.53-9.75m |

- |

|

casing |

4.88-7.62m |

7.62-10.36m |

10.36-14.63m |

Description: oil pipe

Standard: API SPEC 5CT, API SPEC 5B, ISO 11960

Uses: Tubing is used to extract oil or gas from oil wells.

Oil pipe specifications:

|

Size code |

Weight Code |

Outer diameter |

Thickness |

End machining form |

||||||||

|

Steel grade |

||||||||||||

|

unthickened |

thickened |

in |

mm |

in |

mm |

J55 |

L80-1 |

N80 |

C90 |

T95 |

P110 |

|

|

1.900" |

2.40 |

- |

1.900 |

48.26 |

0.125 |

3.18 |

PI |

- |

- |

- |

- |

- |

|

2.75 |

2.90 |

1.900 |

48.26 |

0.145 |

3.68 |

PNUI |

PNUI |

PNUI |

PNUI |

PNUI |

- |

|

|

3.65 |

- |

1.900 |

48.26 |

0.200 |

5.08 |

PU |

PU |

PU |

PU |

PU |

PU |

|

|

2 3/8" |

4.00 |

- |

2.375 |

60.32 |

0.167 |

4.24 |

PN |

PN |

PN |

PN |

PN |

- |

|

4.00 |

4.70 |

2.375 |

60.32 |

0.190 |

4.83 |

PNU |

PNU |

PNU |

PNU |

PNU |

- |

|

|

5.80 |

5.95 |

2.375 |

60.32 |

0.254 |

6.45 |

- |

PNU |

PNU |

PNU |

PNU |

PNU |

|

|

6.60 |

- |

2.375 |

60.32 |

0.259 |

7.49 |

- |

P |

- |

P |

P |

PNU |

|

|

7.35 |

7.45 |

2.375 |

60.32 |

0.336 |

8.53 |

- |

PU |

- |

PU |

PU |

- |

|

|

2 7/8" |

6.40 |

6.50 |

2.875 |

73.02 |

0.217 |

5.51 |

PNU |

PNU |

PNU |

PNU |

PNU |

- |

|

7.80 |

7.90 |

2.875 |

73.02 |

0.276 |

7.01 |

- |

PNU |

PNU |

PNU |

PNU |

PNU |

|

|

8.60 |

8.70 |

2.875 |

73.02 |

0.308 |

7.82 |

- |

PNU |

PNU |

PNU |

PNU |

PNU |

|

|

9.35 |

9.45 |

2.875 |

73.02 |

0.340 |

8.64 |

- |

PU |

- |

PU |

PU |

PNU |

|

|

10.50 |

- |

2.875 |

73.02 |

0.392 |

9.96 |

- |

P |

- |

P |

P |

- |

|

|

11.50 |

- |

2.875 |

73.02 |

0.440 |

11.18 |

- |

P |

- |

P |

P |

- |

|

|

3 1/2" |

7.70 |

- |

3.500 |

88.90 |

0.216 |

5.49 |

PN |

PN |

PN |

PN |

PN |

- |

|

9.20 |

9.30 |

3.500 |

88.90 |

0.254 |

6.54 |

PNU |

PNU |

PNU |

PNU |

PNU |

- |

|

|

10.20 |

- |

3.500 |

88.90 |

0.289 |

7.34 |

PN |

PN |

PN |

PN |

PN |

PNU |

|

|

12.70 |

12.95 |

3.500 |

88.90 |

0.375 |

9.52 |

- |

PNU |

PNU |

PNU |

PNU |

- |

|

|

14.30 |

- |

3.500 |

88.90 |

0.430 |

10.92 |

- |

P |

- |

P |

P |

PNU |

|

|

15.50 |

- |

3.500 |

88.90 |

0.476 |

12.00 |

- |

P |

- |

P |

P |

- |

|

|

17.00 |

- |

3.500 |

88.90 |

0.530 |

13.46 |

- |

P |

- |

P |

P |

- |

|

|

4" |

9.50 |

- |

4.000 |

101.60 |

0.226 |

5.74 |

PN |

PN |

PN |

PN |

PN |

- |

|

10.70 |

11.00 |

4.000 |

101.60 |

0.262 |

6.65 |

PU |

PU |

PU |

PU |

PU |

- |

|

|

4 1/2" |

12.60 |

12.75 |

4.500 |

114.30 |

0.271 |

6.88 |

PNU |

PNU |

PNU |

PNU |

PNU |

- |

|

15.20 |

- |

4.500 |

114.30 |

0.337 |

8.56 |

- |

P |

- |

P |

P |

- |

|

|

17.00 |

- |

4.500 |

114.30 |

0.380 |

9.65 |

- |

P |

- |

P |

P |

- |

|

|

18.90 |

- |

4.500 |

114.30 |

0.430 |

10.92 |

- |

P |

- |

P |

P |

- |

|

|

21.50 |

- |

4.500 |

114.30 |

0.500 |

12.70 |

- |

P |

- |

P |

P |

- |

|

|

23.70 |

- |

4.500 |

114.30 |

0.560 |

14.22 |

|

P |

|

P |

P |

- |

|

|

26.10 |

- |

4.500 |

114.30 |

0.630 |

16.00 |

- |

P |

- |

P |

P |

- |

|

Note: P - flat head; N - no thickening; U - external thickening; T&C - turning thread with coupling; I - integral joint.

Description: casing

Standard: API SPEC 5CT, API SPEC 5B, ISO 11960

Casing specifications:

|

Size code |

Weight code |

Outer diameter |

Thickness |

End machining form |

|||||||||

|

Steel grade |

|||||||||||||

|

in |

mm |

in |

mm |

J55 |

L80-1 |

N80 |

C90 |

C95 |

T95 |

P110 |

M65 |

||

|

4 1/2" |

9.50 |

4.500 |

114.30 |

0.205 |

5.21 |

PS |

- |

- |

- |

- |

- |

- |

- |

|

10.50 |

4.500 |

114.30 |

0.224 |

5.69 |

PSB |

- |

- |

- |

- |

- |

- |

- |

|

|

11.60 |

4.500 |

114.30 |

0.250 |

6.35 |

PSLB |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

|

|

13.50 |

4.500 |

114.30 |

0.290 |

7.37 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

|

|

15.10 |

4.500 |

114.30 |

0.337 |

8.56 |

- |

- |

- |

- |

- |

- |

PLB |

- |

|

|

5" |

11.50 |

5.000 |

127.00 |

0.220 |

5.59 |

PS |

- |

- |

- |

- |

- |

- |

- |

|

13.00 |

5.000 |

127.00 |

0.253 |

7.52 |

PSLB |

- |

- |

- |

- |

- |

- |

- |

|

|

15.00 |

5.000 |

127.00 |

0.296 |

9.19 |

PSLB |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

|

|

18.00 |

5.000 |

127.00 |

0.362 |

9.19 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

|

|

21.40 |

5.000 |

127.00 |

0.437 |

11.10 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

|

|

23.20 |

5.000 |

127.00 |

0.478 |

12.14 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

|

|

24.10 |

5.000 |

127.00 |

0.500 |

12.70 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

|

|

5 1/2" |

14.00 |

5.500 |

139.70 |

0.244 |

6.20 |

PS |

- |

- |

- |

- |

- |

- |

- |

|

15.50 |

5.500 |

139.70 |

0.275 |

6.98 |

PSLB |

- |

- |

- |

- |

- |

- |

- |

|

|

17.00 |

5.500 |

139.70 |

0.304 |

7.72 |

PSLB |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

|

|

20.00 |

5.500 |

139.70 |

0.361 |

9.17 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

|

|

23.00 |

5.500 |

139.70 |

0.415 |

10.54 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

|

|

26.80 |

5.500 |

139.70 |

0.500 |

12.70 |

- |

- |

- |

P |

- |

P |

P |

P |

|

|

29.70 |

5.500 |

139.70 |

0.562 |

14.27 |

- |

- |

- |

P |

- |

P |

P |

P |

|

|

32.60 |

5.500 |

139.70 |

0.625 |

15.88 |

- |

- |

- |

P |

- |

P |

P |

P |

|

|

35.30 |

5.500 |

139.70 |

0.687 |

17.45 |

- |

- |

- |

P |

- |

P |

P |

P |

|

|

38.00 |

5.500 |

139.70 |

0.750 |

19.05 |

- |

- |

- |

P |

- |

P |

P |

P |

|

|

40.50 |

5.500 |

139.70 |

0.812 |

20.62 |

- |

- |

- |

P |

- |

P |

P |

P |

|

|

43.10 |

5.500 |

139.70 |

0.875 |

22.22 |

- |

- |

- |

P |

- |

P |

P |

P |

|

|

6 5/8" |

20.00 |

6.625 |

168.28 |

0.288 |

7.32 |

PSLB |

- |

- |

- |

- |

- |

- |

- |

|

24.00 |

6.625 |

168.28 |

0.352 |

8.94 |

PSLB |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

|

|

28.00 |

6.625 |

168.28 |

0.417 |

10.59 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

|

|

32.00 |

6.625 |

168.28 |

0.475 |

12.06 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

|

|

7" |

20.00 |

7.000 |

177.80 |

0.272 |

6.91 |

PS |

- |

- |

- |

- |

- |

- |

PS |

|

23.00 |

7.000 |

177.80 |

0.317 |

8.05 |

PSLB |

PLB |

PLB |

PLB |

PLB |

- |

- |

PLB |

|

|

26.00 |

7.000 |

177.80 |

0.362 |

9.19 |

PSLB |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

|

|

29.00 |

7.000 |

177.80 |

0.408 |

10.36 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

|

|

32.00 |

7.000 |

177.80 |

0.453 |

11.51 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

|

|

35.00 |

7.000 |

177.80 |

0.498 |

12.65 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

|

|

38.00 |

7.000 |

177.80 |

0.540 |

13.72 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

|

|

7 5/8" |

26.40 |

7.625 |

193.68 |

0.328 |

8.33 |

PSLB |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

- |

|

29.70 |

7.625 |

193.68 |

0.375 |

9.52 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

|

|

33.70 |

7.625 |

193.68 |

0.430 |

10.92 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

|

|

39.00 |

7.625 |

193.68 |

0.500 |

12.70 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

|

|

42.80 |

7.625 |

193.68 |

0.562 |

14.27 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

|

|

45.30 |

7.625 |

193.68 |

0.595 |

15.11 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

|

|

47.10 |

7.625 |

193.68 |

0.625 |

15.88 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

|

|

8 5/8" |

24.00 |

8.625 |

219.08 |

0.264 |

6.71 |

PS |

- |

- |

- |

, - |

- |

- |

- |

|

28.00 |

8.625 |

219.08 |

0.304 |

7.72 |

- |

- |

- |

- |

- |

- |

- |

- |

|

|

32.00 |

8.625 |

219.08 |

0.352 |

8.94 |

PSLB |

- |

- |

- |

- |

- |

- |

- |

|

|

36.00 |

8.625 |

219.08 |

0.400 |

10.16 |

PSLB |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

- |

|

|

40.00 |

8.625 |

219.08 |

0.450 |

11.43 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

|

|

44.00 |

8.625 |

219.08 |

0.500 |

12.70 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

|

|

49.00 |

8.625 |

219.08 |

0.557 |

14.15 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

|

|

9 5/8" |

32.30 |

9.625 |

244.48 |

0.312 |

7.92 |

- |

- |

- |

- |

- |

- |

- |

- |

|

36.00 |

9.625 |

244.48 |

0.352 |

8.94 |

PSLB |

- |

- |

- |

- |

- |

- |

PSLB |

|

|

40.00 |

9.625 |

244.48 |

0.395 |

10.03 |

PSLB |

PLB |

PLB |

PLB |

PLB |

PLB |

- |

PSLB |

|

|

43.50 |

9.625 |

244.48 |

0.435 |

11.05 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

- |

|

|

47.00 |

9.625 |

244.48 |

0.472 |

11.99 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

- |

|

|

53.50 |

9.625 |

244.48 |

0.545 |

13.84 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

- |

|

|

58.40 |

9.625 |

244.48 |

0.595 |

15.11 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

PLB |

- |

|

|

59.40 |

9.625 |

244.48 |

0.609 |

15.47 |

- |

- |

- |

P |

- |

P |

- |

- |

|

|

64.90 |

9.625 |

244.48 |

0.672 |

17.07 |

- |

- |

- |

P |

- |

P |

- |

- |

|

|

70.30 |

9.625 |

244.48 |

0.734 |

18.64 |

- |

|

- |

P |

- |

P |

- |

- |

|

|

75.60 |

9.625 |

244.48 |

0.797 |

20.24 |

- |

- |

- |

P |

- |

P |

- |

- |

|

|

10 3/4" |

32.75 |

10.750 |

273.05 |

0.279 |

7.09 |

- |

- |

- |

- |

- |

- |

- |

- |

|

40.50 |

10.750 |

273.05 |

0.350 |

8.89 |

PSB |

- |

- |

- |

- |

- |

- |

PSB |

|

|

45.50 |

10.750 |

273.05 |

0.400 |

10.16 |

PSB |

- |

- |

- |

- |

- |

- |

PSB |

|

|

51.00 |

10.750 |

273.05 |

0.450 |

11.43 |

PSB |

PSB |

PSB |

PSB |

PSB |

PSB |

PSB |

PSB |

|

|

55.50 |

10.750 |

273.05 |

0.495 |

12.57 |

- |

PSB |

PSB |

PSB |

PSB |

PSB |

PSB |

PSB |

|

|

60.70 |

10.750 |

273.05 |

0.545 |

13.34 |

- |

- |

- |

PSB |

- |

PSB |

PSB |

- |

|

|

65.70 |

10.750 |

273.05 |

0.595 |

15.11 |

- |

- |

- |

PSB |

- |

PSB |

PSB |

- |

|

|

73.20 |

10.750 |

273.05 |

0.672 |

17.07 |

- |

- |

|

P |

- |

P |

- |

- |

|

|

79.20 |

10.750 |

273.05 |

0.734 |

18.64 |

- |

- |

- |

P |

- |

P |

- |

- |

|

|

85.30 |

10.750 |

273.05 |

0.797 |

20.24 |

- |

- |

- |

P |

- |

P |

- |

- |

|

|

11 3/4" |

42.00 |

11.750 |

298.45 |

0.333 |

8.46 |

- |

- |

- |

- |

- |

- |

- |

- |

|

47.00 |

11.750 |

298.45 |

0.375 |

9.53 |

PSB |

- |

- |

- |

- |

- |

- |

PSB |

|

|

54.00 |

11.750 |

298.45 |

0.435 |

11.05 |

PSB |

- |

- |

- |

- |

- |

- |

PSB |

|

|

60.00 |

11.750 |

298.45 |

0.489 |

12.42 |

PSB |

PSB |

PSB |

PSB |

PSB |

PSB |

PSB |

PSB |

|

|

65.00 |

11.750 |

298.45 |

0.534 |

13.56 |

- |

P |

P |

P |

P |

P |

P |

- |

|

|

71.0 |

11.750 |

298.45 |

0.582 |

14.78 |

- |

P |

P |

P |

P |

P |

P |

- |

|

|

13 3/8" |

48.00 |

13.375 |

339.72 |

0.330 |

8.38 |

- |

- |

- |

- |

- |

- |

- |

- |

|

54.50 |

13.375 |

339.72 |

0.380 |

9.65 |

PSB |

- |

- |

- |

- |

- |

- |

PSB |

|

|

61.00 |

13.375 |

339.72 |

0.430 |

10.92 |

PSB |

- |

- |

- |

- |

- |

- |

PSB |

|

|

68.00 |

13.375 |

339.72 |

0.480 |

12.19 |

PSB |

PSB |

PSB |

PSB |

PSB |

PSB |

PSB |

PSB |

|

|

72.00 |

13.375 |

339.72 |

0.514 |

13.06 |

- |

PSB |

PSB |

PSB |

PSB |

PSB |

PSB |

- |

|

|

16 |

65.00 |

- |

406.40 |

- |

9.53 |

- |

- |

- |

- |

- |

- |

- |

- |

|

16 |

75.00 |

- |

406.40 |

- |

11.13 |

- |

- |

- |

- |

- |

- |

- |

- |

|

16 |

84.00 |

- |

406.40 |

- |

12.57 |

- |

- |

- |

- |

- |

- |

- |

- |

|

16 |

109.00 |

- |

406.40 |

- |

16.66 |

- |

- |

- |

- |

- |

- |

- |

- |

|

18 5/8" |

87.20 |

- |

473.08 |

- |

11.05 |

- |

- |

- |

- |

- |

- |

- |

- |

|

20 |

94.00 |

- |

508.00 |

- |

11.13 |

- |

- |

- |

- |

- |

- |

- |

- |

|

20 |

106.50 |

- |

508.00 |

- |

12.70 |

- |

- |

- |

- |

- |

- |

- |

- |

|

20 |

133.00 |

- |

508.00 |

- |

16.13 |

- |

- |

- |

- |

- |

- |

- |

- |

Note: P--Flat end; S--Short round thread; L--Long round thread; B--Bias trapezoidal thread

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- SHANDONG HUITONG STEEL CO.,LTD

- *Message:

-

Submit

Main Product:

Seamless Steel Pipe,

Carbon Steel Plate,

Galvanized Steel Coil,

Color Coated Roll ,

Corrugated Roofing Sheet,

Welded Pipe

You May Also Like