Transparent polygonal aluminum shell

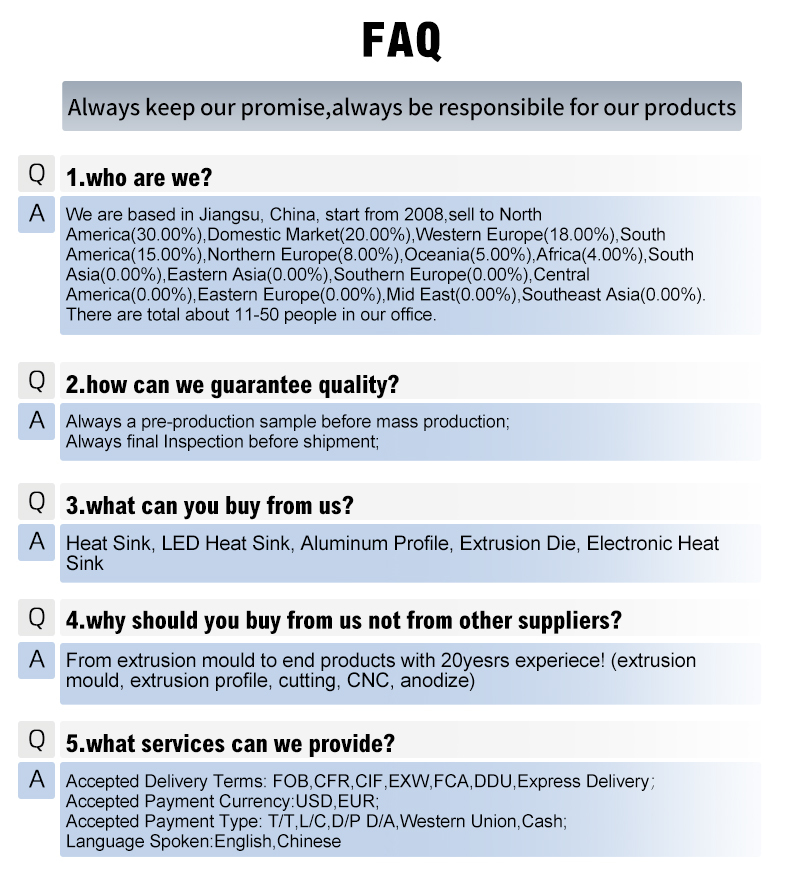

12 month agoCompression springs work by storing potential energy when they are compressed, and then releasing that energy to return to their original shape when the force is removed. This makes them useful in a wide range of applications, including automotive, aerospace, industrial, and medical devices.

Compression springs can vary in size, shape, and strength depending on the specific requirements of the application. They are often used to provide resistance or support, absorb shock or impact, maintain pressure, or store and release energy.

Some common examples of compression spring applications include:

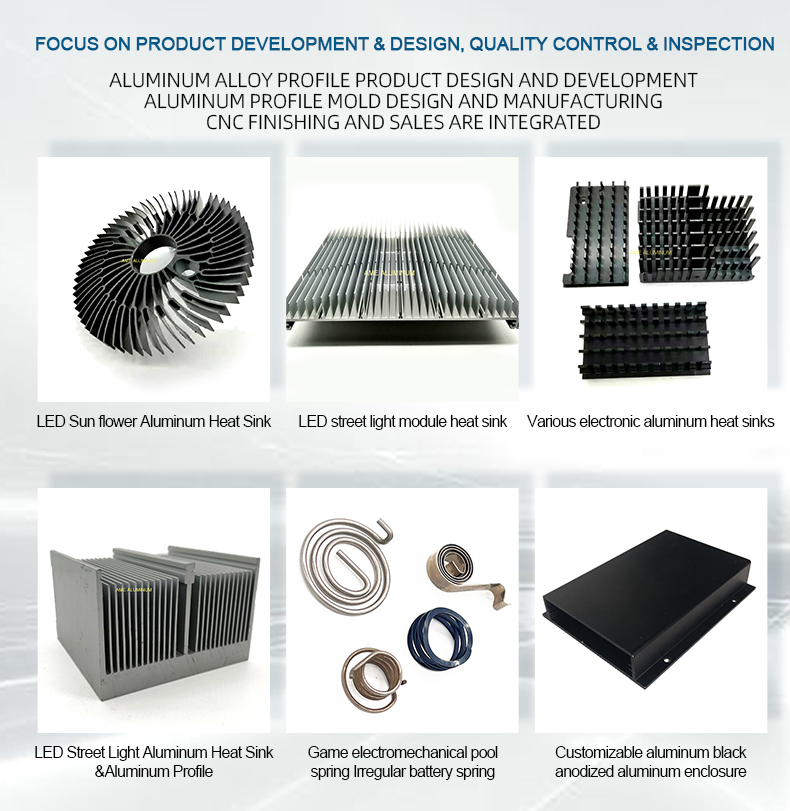

Heatsink For Solar Energy Systems,Solar Panel Heatsink,Heat Sink, Irregular Aluminum Heat Sink

- Suspension systems in vehicles

- Valve actuators in plumbing and HVAC systems

- Cushioning or shock absorption in mattresses or furniture

- Force measurement or calibration devices

- Electrical switches or connectors

- Exercise equipment or toys

Compression springs are typically manufactured using a coiling process, where a wire is wound around a mandrel or rod to form the desired shape. The wire diameter, coil diameter, and number of coils can all be customized to achieve the desired spring characteristics, such as stiffness or load capacity.

Overall, compression springs are a versatile and widely used type of spring that provide reliable and consistent performance in a variety of applications.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Suzhou AME Aluminum Product Co.,Ltd

- *Message:

-

Submit

Main Product:

Aluminum Heat Sink,

Aluminum Profile,

Aluminum Enclosure,

Metal Spring ,

cnc precision machining,

Metal Stamping