Coconut shell complete production line

11 month agoThis article introduces you to the detailed information of the complete set of activated carbon production line equipment.

| Ash Content:≤5% | Processing Technology: Physical Activation |

| Hardness: ≥90% | Product Form: Powder, Granular, Columnar |

| Iodine Adsorption Value: ≥1100mg/g | Production Capacity: Customized Raw |

| Packaging: 25kg/bag、1000kg/bag | Material: Coal, Coconut Shell, Wood, Etc. |

| Heat source: Originating from boredom itself | Application areas: chemical industry/water purification/gold adsorption/aerospace/medicine/decolorization |

| System admixture (activated carbon) | 4-5T/DAY |

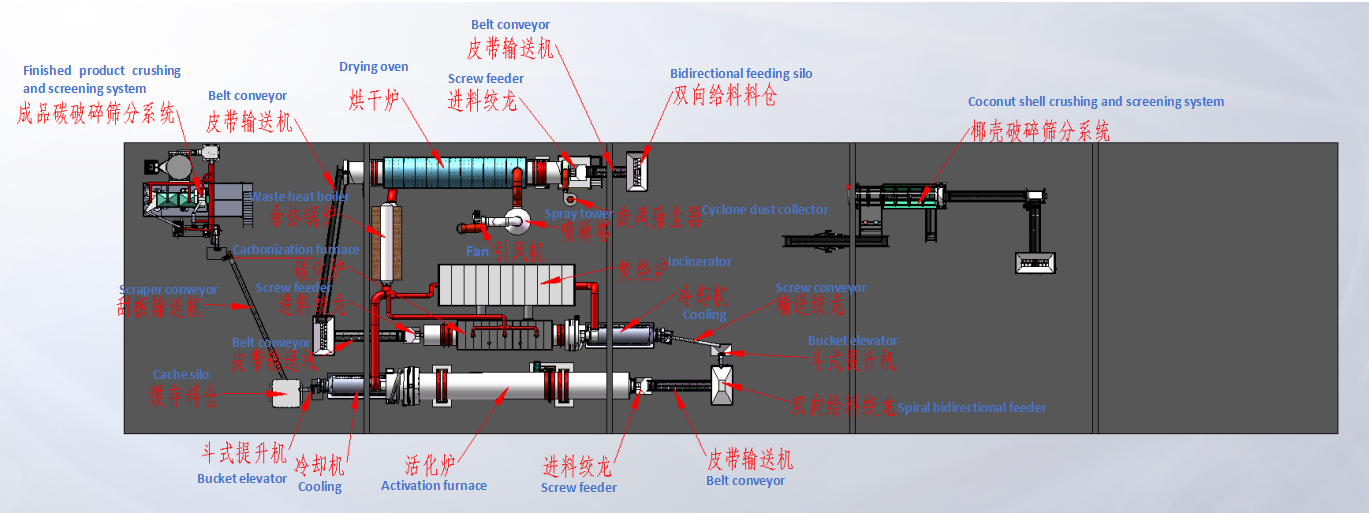

This production line produces activated carbon, which mainly consists of coconut shell, peach shell, apricot shell, wood, cocoa shell, hazelnut shell and palm shell as raw materials. The specific process flow is as follows:

Ⅰ. Equipment for pre-treatment of raw materials (taking coconut shell as an example): Coconut shell contains various impurities such as soil lumps, gravel, shredded coconut, coconut hair, and the size of coconut shell varies. Therefore, we need to crush, remove impurities, and screen out suitable materials (<5cm) from coconutshell.

Ⅱ. Drying system for raw materials

If the material after pre-treatment has high moisture content, we need to use a rolling dryer for drying. Our goal is to reducethe pressure on the rear carbonization system and improve the yield and yield of the carbonized material.

Ⅲ. Carbonation furnace system

After drying, the moisture content of the materials is basically less than 10%. At this time, these materials enter the carbonization furnace through the conveying system for high-temperature carbonization. This step mainly removes most of the fugitive constituent contained in the material, leaving only a small portion of the fugitive constituent.

During the carbonization process, a large amount of flue gas will appear. This part of the flue gas will be sent to the incinerator for high-temperature incineration through the action of an induced draft fan. The heat generated by the incineration flue gas is used to heat the steam boiler, and the remaining waste heat enters the combustion chamber of the cylinder for incineration, which is also a heat source required for the operation of the carbonization furnace. The entire system has no additional heat source supply, truly achieving the cyclic utilization of heat.

Ⅳ. Activation furnace system

The carbonized charcoal is transported by the conveying system to the interior of the activation furnace for machining. The internal temperature of the furnace body is about 900-1000 ℃. At this time, the charcoal will burn off the remaining fugitive constituent under high temperature conditions. The steam generated by the steamboiler will be transported to the interior of the activation furnace through the steam pipeline, fully reacting with the charcoal. This step is the most important "pore forming". The steam generated during the activation process enters the rear heat storage chamber for combustion, and the heat generated will also be used as the heat during the operation of the activation furnace. The activation furnace is internally made of Fire brick, which will play a very good heat preservation effect, so as to ensure the steam activation effect of materials, better ensure the temperature in the furnace, and finally produce high-quality activated carbon.

Ⅴ. Deep processing system of activated carbon

The activated carbon processed by the activation furnace has different specifications and sizes. At this time, deep processing equipment needs to be used to process it. Different shapes of activated carbon need to be crushed, screened, impurities removed, stones removed, magnetic separation, and other steps. The specific specifications need to be done according to the customer's requirements. After the activated carbon completes this step, it can be sold to earn corresponding profits.

If you are interested in our activated carbon equipment, we are willing to provide you with relevant knowledge and equipment. We look forward to your consultation.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Shandong Hengyi kaifeng Machinery Co.,Ltd

- *Message:

-

Submit

Main Product:

Activation Furnace,

Carbonization Furnace ,

Activated Carbon Equipment,

Activated Carbon Regeneration Equipment,

Flour Mill,

Large Flour Mill

You May Also Like