PEAKSUN(MT)-Nozzle#6

10 month agoProduct Overview

OEM Cemented Tungsten Carbide Nozzles for Drill Bits are highly specialized components that are essential in the drilling industry. Manufactured with original equipment manufacturer (OEM) standards, these nozzles are crafted from top-quality tungsten carbide. They are designed to be integrated into drill bits and play a crucial role in optimizing the drilling process. These nozzles are engineered to withstand the harsh conditions of drilling operations and ensure efficient fluid flow and distribution, which is vital for effective hole cleaning and rock fragmentation.

Material Characteristics

Constructed from tungsten carbide, these nozzles possess outstanding material properties. Tungsten carbide is known for its extreme hardness, which enables the nozzles to resist abrasion and wear caused by the contact with drilling fluids and the drilled material. It has excellent heat resistance, allowing it to function properly even under the high temperatures generated during drilling. The material also exhibits good chemical stability, making it suitable for use with a variety of drilling fluids and in different geological formations.

Product Advantages

• Superior Durability: The tungsten carbide material provides exceptional resistance to wear and tear, ensuring a long lifespan and reducing the need for frequent nozzle replacements. This leads to lower maintenance costs and increased operational efficiency.

• Precision Machining: The nozzles are precision-machined to have accurate dimensions and smooth surfaces. This precision allows for optimal fluid flow patterns, ensuring efficient transfer of drilling fluids and enhancing the overall drilling performance.

• Versatile Designs: Available in various designs and configurations such as spray, jet, and swivel nozzles. This versatility enables them to meet the specific requirements of different drilling applications and geological conditions.

Product Application Areas

• Oil and Gas Drilling: Crucial in drilling operations for the extraction of oil and gas. They are involved in fluid injection, pressure control, and debris removal, which are essential for maintaining the efficiency and safety of the well.

• Geotechnical Drilling: Used in soil sampling, foundation investigations, and other geotechnical drilling activities. Their durability and precision help in obtaining accurate samples and ensuring the integrity of the drilling process.

• Mineral Exploration: Facilitate the drilling process in search of mineral deposits. The ability to withstand the abrasion from hard rock and provide efficient fluid handling is vital for successful exploration.

Product Specifications and Customization Requirements

• Specifications: Offered in different sizes with inner diameters typically ranging from millimeters and lengths from millimeters. The flow rate capabilities can vary from liters per minute, depending on the nozzle design and application.

• Customization: Customization options are available. Customers can request specific nozzle geometries, such as different spray angles or orifice shapes, to suit their particular drilling needs. Additionally, the surface finish of the nozzles can be adjusted to optimize fluid flow and reduce friction. For example, in deep-sea oil drilling, where the conditions are more extreme, a customized nozzle with enhanced corrosion resistance and a specific flow rate pattern might be required.

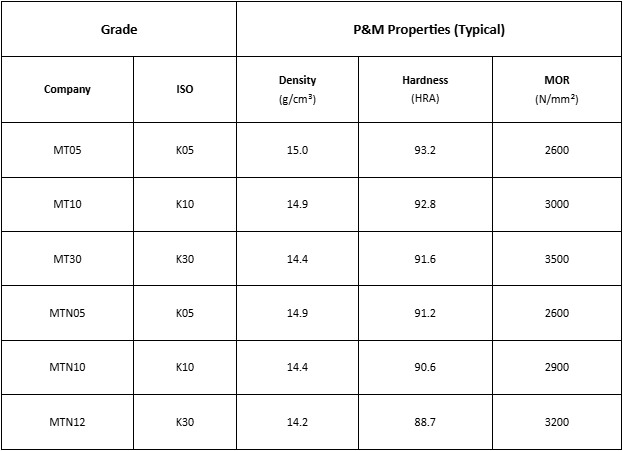

Grade

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Zigong MT Cemented Carbide Tech Co., Ltd.

- *Message:

-

Submit

Main Product:

Oli& Gas wear parts,

Mechanical seal,

Carbide tipped tools,

Slitting blades ,

Mulcher tooth,

Cemented tungsten carbide