DKD01-08DKD01-08

10 month ago### Properties of Conductive Plastic Films

Conductive plastic films are engineered to exhibit electrical conductivity while maintaining the beneficial properties of plastics, such as flexibility, lightweight, and durability. Key properties include:

1. **Electrical Conductivity**: Achieved through the incorporation of conductive fillers like carbon black, carbon nanotubes, graphene, or metallic nanoparticles. These fillers create conductive pathways within the plastic matrix.

2. **Flexibility**: Unlike rigid metal conductors, conductive plastic films can bend, stretch, and conform to various shapes, making them suitable for flexible electronic applications.

3. **Lightweight**: Plastics are inherently lighter than metals, which is advantageous in applications where weight reduction is crucial, such as in aerospace and automotive industries.

4. **Durability**: These films are resistant to corrosion, chemical exposure, and mechanical stress, ensuring long-term performance in diverse environments.

### Manufacturing Process

The production of conductive plastic films involves several key steps:

1. **Selection of Base Polymer**: Common polymers used include polyethylene (PE), polypropylene (PP), polycarbonate (PC), and polyvinyl chloride (PVC).

2. **Incorporation of Conductive Fillers**: Conductive materials like carbon black, carbon nanotubes, graphene, or metallic nanoparticles are mixed with the polymer. The concentration and type of filler determine the level of conductivity.

3. **Extrusion or Coating**: The conductive polymer blend is processed into films using extrusion or coating techniques. During extrusion, the material is melted and formed into thin films, while coating involves applying the conductive polymer onto a substrate.

4. **Post-Processing**: This may include stretching, annealing, or surface treatments to enhance the film's mechanical and electrical properties.

### Applications

Conductive plastic films are used in a variety of applications across multiple industries:

1. **Electronics**: These films are integral in the production of flexible circuits, touchscreens, sensors, and wearable electronics. Their flexibility allows for innovative designs in consumer electronics.

2. **EMI Shielding**: Conductive films are used to protect electronic devices from electromagnetic interference (EMI), ensuring the proper functioning of sensitive components.

3. **Static Dissipation**: In environments where static electricity poses risks, such as in cleanrooms or electronic assembly lines, conductive films help dissipate static charges.

4. **Energy Storage**: These films are used in batteries and capacitors, where they serve as conductive layers or separators, enhancing the performance and safety of energy storage devices.

5. **Automotive and Aerospace**: Conductive plastic films are used in lightweight, flexible wiring systems, sensors, and other components, contributing to the weight reduction and increased efficiency of vehicles and aircraft.

6. **Packaging**: In the packaging industry, conductive films are used for antistatic packaging to protect electronic components during transportation and storage.

1. Packaging

2. Folding boxes

3. Vacuum thermoforming

4. Blister packaging for drinks, foods, stationery, toys, tools, gifts, medicines and more.

Shandong Top Leader Plastic packing Co.,Ltd was established in November, 1999. As a large-scale private enterprise with more than 500 staffs, our company is a major market player in plastic film and film manufacturer at North China. Our company pursues "people oriented policy" in human resource management and persists in applying "realistic approach, innovative mentality, quality consistency and efficient administration" as our core value. Strong technical force, advanced production equipment, our company embedded 14 calender lines, 10 printing machines, 10 lamination and emboss machines to supply products of common transparent film, super transparent film, electrostatic protective film, inkjet advertising film, trademark film, protective film gum paste, electricians film, grainy film, sound film, steel film, furniture membrane pressing film, etc. Totally 64 production lines, and the production of pvc sheet, PE sheet,pet sheet, Petg Sheet, GAG sheet ,PP Sheet, PS Sheet ,PC sheet ,pla sheet ,Biodegradable material film and Composite Plastic Film widely used in food packaging, pharmaceutical packaging, electronic tray, metal packaging , Handicraft packaging and other fields.

All of our quality management is complied with ISO9001-2008 Quality Assurance Certificate and SGS Quality Assurance Certificate . We also apply "customer first, satisfaction service" to provide a comprehensive process service value on our products. As a result our products have covered all over the world market. We sincerely welcome customers and friends from home and abroad for exploration and instruction, to establish extensive cooperation and to create brilliant future together.

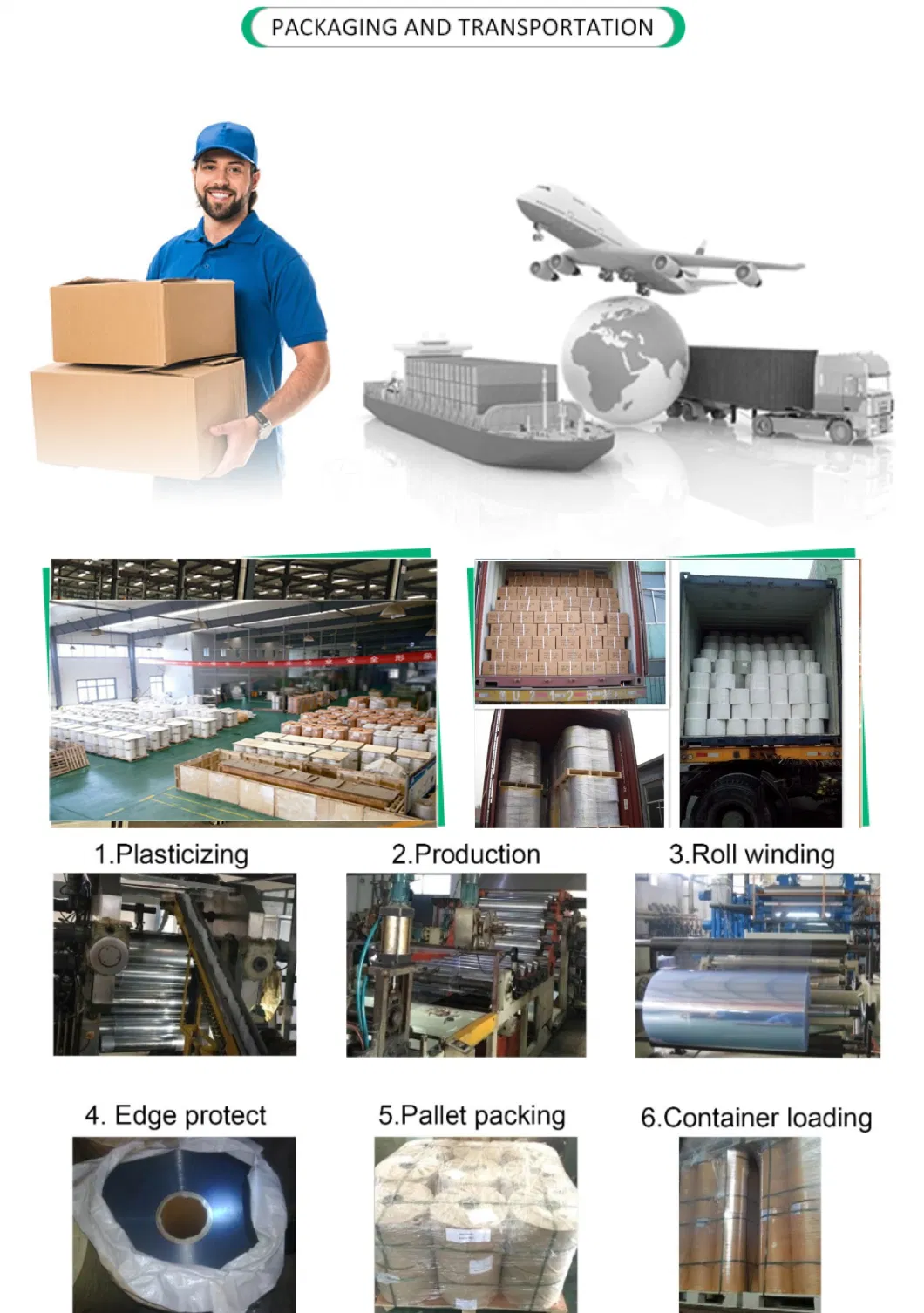

Packing & Delivery:

Packing & Delivery:

A: Generally, we pack our goods in pallet with film packaged.

Q2. What is your terms of payment?

A: T/T 40% as deposit, and 60% before delivery. We'll show you the photos of the products and packages

before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 7 days after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, the customers have to pay the process cost and

the courier cost.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?

A: We keep good quality and competitive price to ensure our customers benefit ;

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Shandong Top Leader Plastic Packing CO., LTD

- *Message:

-

Submit

Main Product:

PVC Rigid Film,

PET PETG Rigid Film,

HIPS Film ,

PC Film,

PP Film,

Other plastic packaging products