Turbine flowmeter uses vortex effect generated by fluid flowing through turbine impeller to measure flow rate. Although it has a simple structure, it has high precision and is suitable for measuring the flow rate of liquid. It is widely used in the field of flow measurement in industrial production, such as petrochemical industry, water treatment, food processing and other industries. It has a wide measuring range and can meet the requirements of different flow ranges.

The disadvantage of turbine flowmeter is that it is sensitive to the changes of fluid viscosity and density, and needs to be calibrated and corrected according to the actual situation. In addition, the application in special environments such as high temperature, high pressure and corrosive media is limited to some extent.

Our main products are: Electromagnetic flowmeter, Energy meter, Vortex flowmeter, Pressure transmitters, Level gauge, Magnetic flap level gauge.

Features

1. Select alloy turbine, which has very good flow stabilization and corrosion resistance.

2. Imported special bearings with long service life

3. The metering room is isolated from the ventilation room to ensure the safety of the instrument.

4, can detect the temperature, pressure and flow of the tested gas, can carry out automatic flow tracking compensation, and display the standard state of gas volume accumulation;

5. The temperature and pressure values can be queried in real time. The flow range is wide, the repeatability is good, the precision is high, the pressure loss is small, and the initial flow is low.

6. Multi-point nonlinear correction of intelligent instrument coefficient

7. Built-in pressure and temperature sensors with high safety performance, compact structure and beautiful appearance

8. The system works with low power consumption. A 3.2V10AH lithium battery can be used continuously for more than 3 years.

9. Instrument coefficient and cumulative flow value will not be lost after power failure for ten yearsProduct Parameters

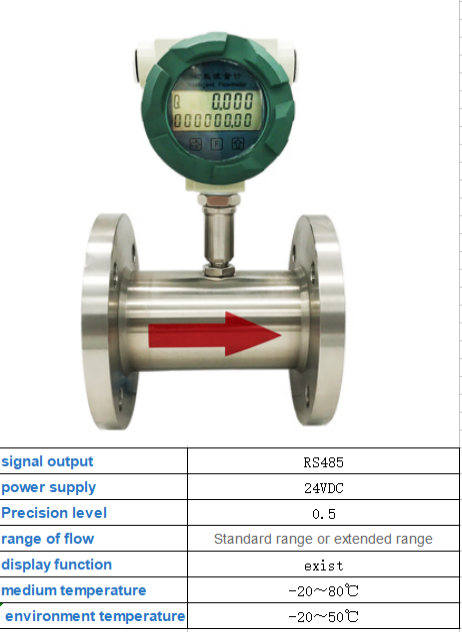

Implementation Standard: Turbine flow sensor (GB/T 8940-2003)

Gauge caliber: DN20 ~ DN300

Accuracy grade: 1.0 (regular);0.5 (specially customized)

Range Ratio: 1:10, 1:20, 1:30 customizable

Sensor material: 304 stainless steel, 316(L) stainless steel, etc.

Application Conditions: medium temperature:-20℃ ~-120℃; Ambient temperature:-20℃ ~ + 50℃;

Relative humidity: 5% ~ 90%; Atmospheric pressure: 86Kpa ~ 106Kpa

Signal output function: 4 ~ 20mA signal, pulse signal, frequency, control level

Communication output function: RS485 communication?

Power supply mode: 24VDC ± 15%/lithium battery power supply

Signal cable interface: He Siman connector, three-core cable, internal thread

Protection level: IP65 or higher (customizable)

Connection mode: Thread (≤dn50), flange (≥dn65)