CNC processing

9 month agoCustom CNC Turning Services And Parts

ShangEn is an experienced precision CNC turning services supplier, manufacturer, exporter in China, has been specialized in offering best OEM CNC lathe services for superior quality low cost CNC lathing/turning parts or high precision machined components with the operation of an impressive range of state-of-the-art turning machines, such as washers, bolts, shafts, rivets, spacers, sleeves, nipples, stainless steel fittings, pipe fittings, light fittings, wheel studs, etc.

Our advanced CNC turning center routinely works with a wide variety of materials, ranging from copper, brass, stainless steel, carbon steel, aluminum, and titanium. We can always choose a suitable precision turning process to reach your requirements. Our custom CNC machining services ensure that our customers receive the highest quality CNC turned parts. Send your inquiry or drawing fast to get an online CNC quote

Our CNC cutting services can cut an extensive range of materials using laser cutting, waterjet, and other technologies. According to your requirements and applications, we’ll offer suggestions for product design, suitable materials, and the most cost-effective methods for sheet cutting. Minimal cost, time, and best quality are our purposes. Equipped with state-of-the-art facilities and measuring equipment in our factory, CNC metal, and plastic cutting now supplies CNC machining parts for a number of business sectors and private individuals, catering to both long and short production runs. Fast to send your inquiry or submit your drawings to get a free quote in the shortest time.

Our company also has the most advanced and complete inspection equipment in the castingindustry, including Spectrometer, Metallographic Microscope, Tension Tester, LowTemperature Tester, X-ray Tester, MPT, UT, CMM, Video Measurement Machine and so on.With these advanced facilities & instruments, we are able to supply the most precise finishedproducts to our customers, and make products meeting their overall inspection requirementson chemical composition, mechanical properties, non-destructive testing and high precisedimensional inspections.

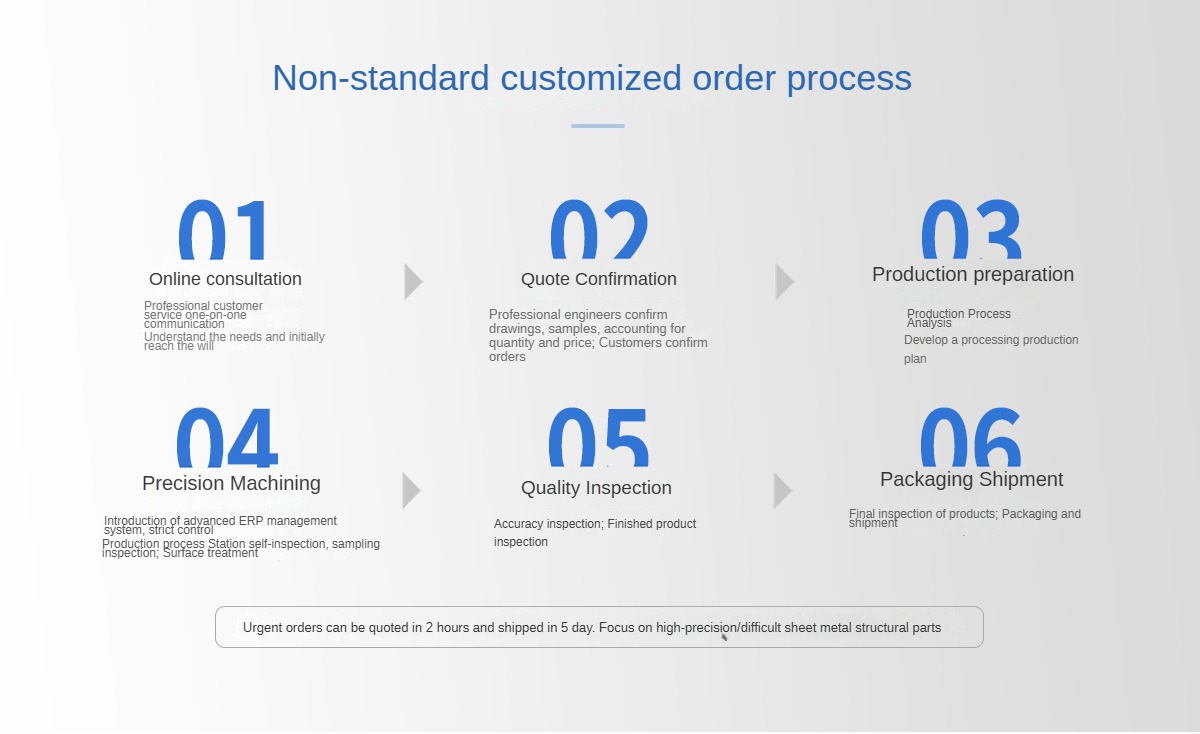

1) Checking the raw material after they reach our factory. incoming quality control (lQC

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process qualitycontrol(lPQC)

4) Checking the goods after they are finished... Final quality control(FQC

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Dongguan Shangen Precision Metal Plate Co., Ltd.

- *Message:

-

Submit

Main Product:

Sheet Metal Fabrication,

Fabrication Services,

Sheet Metal Bracket,

Hardware tools,

CNC Machining Parts ,

Sheet metal box case

You May Also Like