Customized sheet metal fabrication stamping parts involve the process of material processing, design and manufacturing, and are mainly used to produce metal parts of various shapes and sizes. The following are basic steps and points:

1. Design stage

Requirement analysis: First of all, it is clear that the function, size, material requirements, etc. of the required needed.

Drawing design: Use CAD software for detailed design to ensure that all geometric size, tolerance, and surface treatment are accurate.

2. Material selection

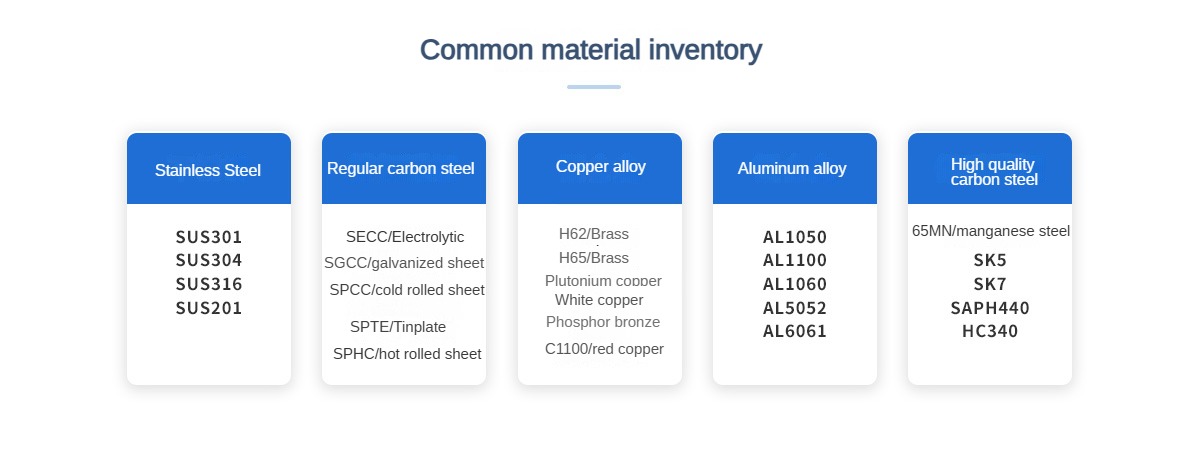

Che the appropriate metal materials according to design needs, such as carbon steel, stainless steel, aluminum alloy, etc.

-In consideration of the strength, corrosion resistance, processing performance of the material.

3. mold design and production

Mold design: Based on design drawings, professional engineers will design a suitable punching mold.

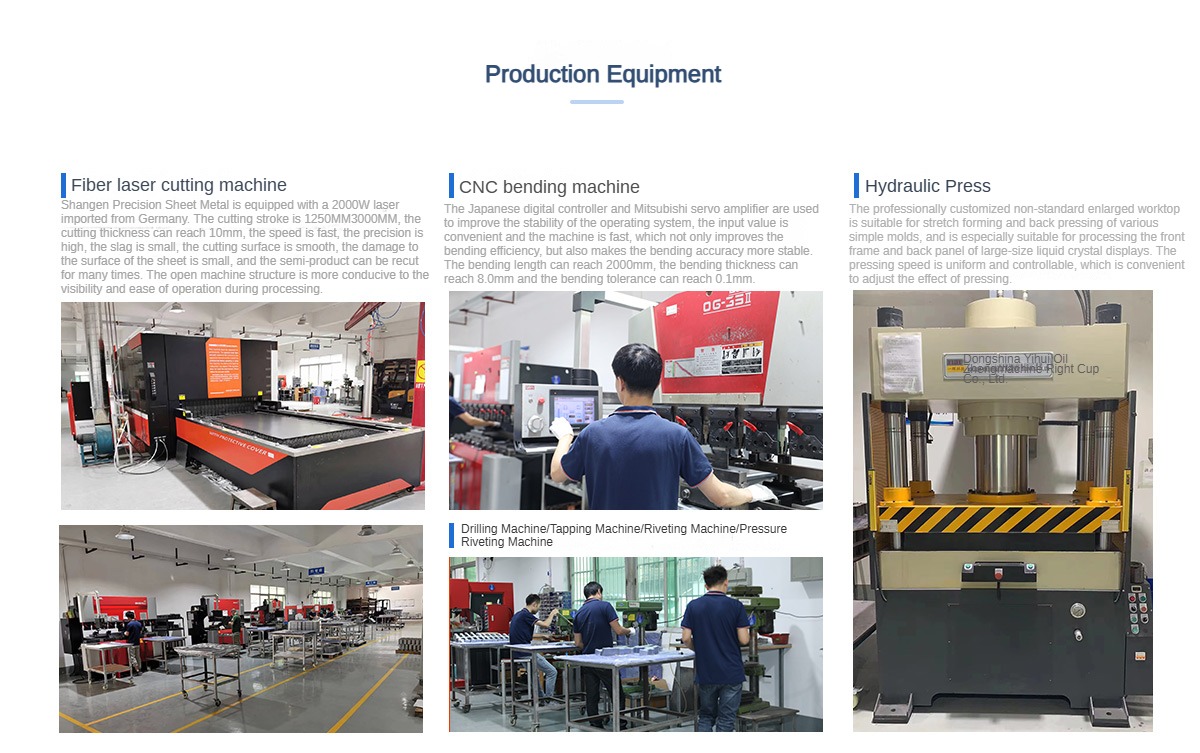

Mold manufacturing: Use the equipment such as CNC machine tools to process molds to ensure accuracy and durability.

4. Pouring the process

Preheat or cooling: According to the material characteristics, the material may need to be preheated or cooled to optimize the stamping effect.

Pouring: Place the material on the mold, and apply force through the pressure machine to make it deformed to form the required shape.

Post -treatment: It may include the steps to remove the burrs, surface polish, cleaning, paint and other steps.

5. Quality control

Inspection : Use various testing tools (such as crickets, microscope) to check whether the size, shape, surface quality, etc. meet the standard.

Test: Perform functional testing if necessary to ensure that the product meets the requirements of use.

6. Packing and delivery

Puk the qualified products to ensure that it is not damaged during transportation.

Chimores according to customer requirements or the time stipulated in the contract.

Note:

In the design and production process, cost benefits should be considered, and materials should be used reasonably to reduce waste.

In strictly abide by the safety production regulations to ensure the safety of the operator.

Contonly communicate well with suppliers to ensure the quality and supply of materials and supply in a timely manner.

Through the above steps, we can realize the efficient and high -quality production of custom sheet metal punching parts.Fast to send your inquiry or submit your drawings to get a free quote in the shortest time.We provide sheet metal fabrication, sheet metal brackets sheet metal box housing hardware tools and any other metal fabrication services as well as machining services,Machining Parts, Hardware tools.

Dongguan Shangen Precision Metal Plate Co., Ltd.