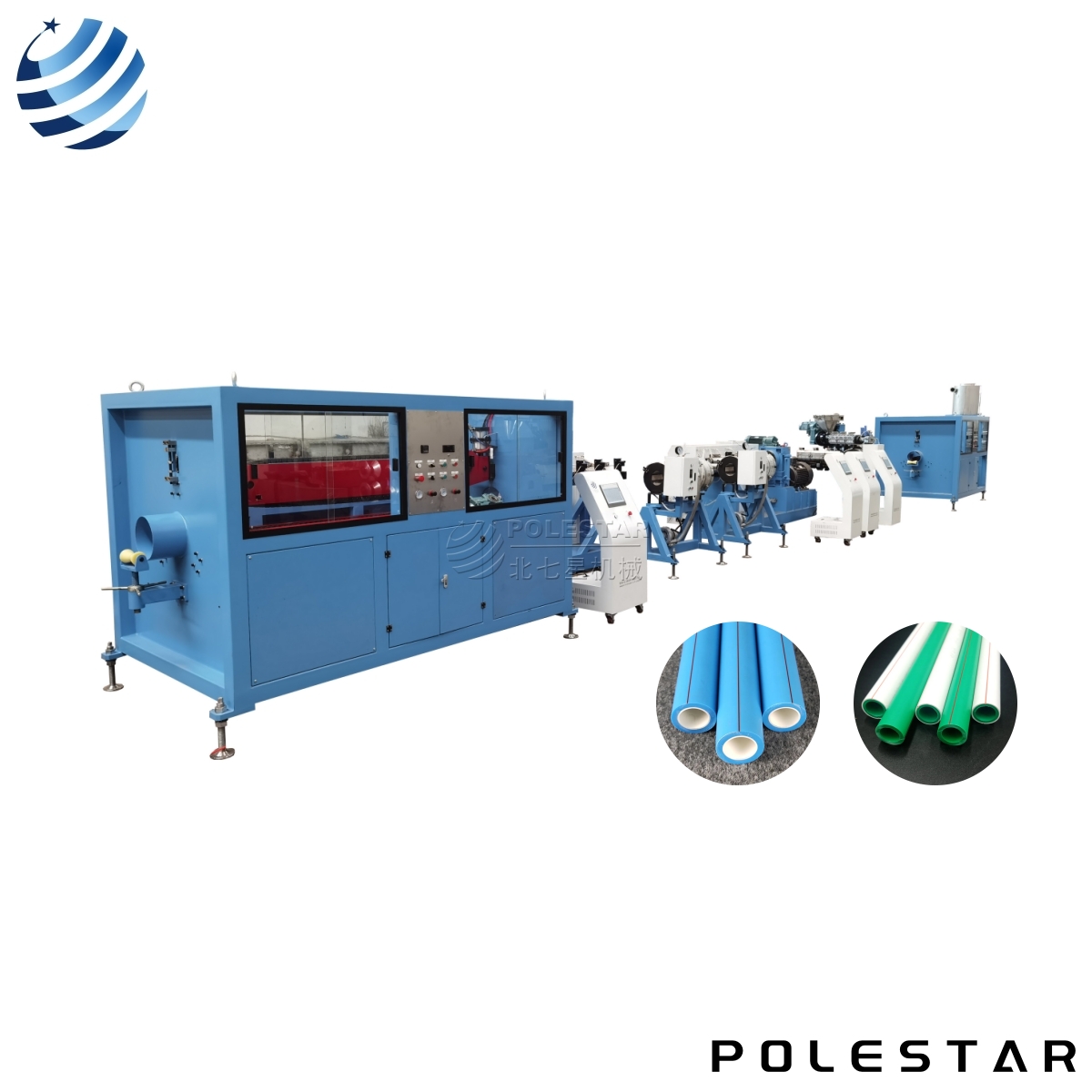

Style 2 Co extrusion machine

10 month ago

- Hot and cold water plumbing, residential and commercial

- Radiant heating and cooling systems (floors, walls, ceilings)

- Fluid piping and distribution (radiators, fan coils, etc.)

- Chilled water pipes

- Exterior snow and ice melting

- Turf conditioning/asphalt heating

- District heating/cooling

- Water service lines (greywater and IPS)

- Geothermal ground loops (vertical drilling, horizontal layout)

- Hot and cold water supply systems:

- PPR pipes are widely used in hot and cold water supply systems in residential, commercial, and industrial buildings. They can withstand high temperatures and pressures and can distribute heat evenly, which makes them ideal for conveying water in such systems. They are also used in heating systems such as underfloor heating, etc.

- Chemical and fluid transport:

- PPR pipes are known to be corrosion-resistant, which makes them best suited to undertake the role of conveying chemicals and fluids in industrial processes.

- Agricultural irrigation applications:

- PPR pipes are widely used in irrigation systems in the agricultural sector due to their durability and resistance to chemicals.

- Infrastructure:

- PPR pipes are also used in infrastructure projects such as sewage systems, drainage systems, and cable ducts. The corrosion and abrasion resistance of these pipes makes them ideal for such applications.

- Conveying liquids and chemicals:

- PPR pipes are used to convey fluids and chemicals in industrial processes. In summary, it can be concluded that these pipes are a versatile and durable choice for a wide range of piping applications.

- This production line is mainly used to produce PP-R pipes, and can also produce PE-RT, PB, PE-X pipes.

- PLC control, touch screen interface, high-level automatic operation.

- Special screw design, good plasticizing effect. Diameter between 20-200mm, aspect ratio can be customized according to needs.

- Adopt composite spiral head to effectively eliminate material property memory. Double mixing head ensures 100% plasticization of melt before die head, which increases production capacity by about 30% compared with ordinary models.

- Vacuum calibration and constant temperature calibration are used to eliminate stress on the inner wall of the pipe.

- Color strips use co-extrusion head.

- Large extrusion volume, low and uniform melt temperature.

- The transmission adopts hard gears, which has the advantages of low noise, stable operation, large load and long service life.

|

Model |

Pipe Range (mm) |

Extruder Model |

Main Motor Power (KW) |

Max Extrusion Output (kg/h) |

|

BQX-PPR63 |

20~63 |

SJ65/33 |

125 |

150 |

|

BQX-PPR110 |

20~110 |

SJ75/33 |

210 |

220 |

|

BQX-PPR160 |

50~160 |

SJ75/33 |

210 |

220 |

|

Cold Water PPR Pipe |

Cold Water PPR Pipe |

Hot Water PPR Pipe |

Hot Water PPR Pipe |

|

PN1.25 (Mpa) |

PN1.6 (Mpa) |

PN2.0 (Mpa) |

PN2.5 (Mpa) |

|

Φ25×2.3 |

Φ20×2.3 |

Φ20×2.8 |

Φ20×3.4 |

|

Φ32×3.0 |

Φ25×2.8 |

Φ25×3.5 |

Φ25×4.2 |

|

Φ40×3.7 |

Φ32×3.6 |

Φ32×4.4 |

Φ32×5.4 |

|

Φ50×4.6 |

Φ40×4.5 |

Φ40×5.5 |

Φ40×6.7 |

|

Φ63×5.8 |

Φ50×5.6 |

Φ50×6.9 |

Φ50×8.3 |

|

Φ75×6.8 |

Φ63×7.1 |

Φ63×8.7 |

Φ63×10.5 |

|

Φ90×8.2 |

Φ75×8.4 |

Φ75×10.3 |

Φ75×12.5 |

|

Φ110×10 |

Φ90×10.1 |

Φ90×12.3 |

Φ90×15.5 |

|

|

Φ110×12.3 |

Φ110×15.1 |

Φ110×18.3 |

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Zhangjiagang Polestar Machinery Co.,Ltd

- *Message:

-

Submit

Main Product:

WPC Extrusion Line,

Plastic Pipe Extrusion Line,

Plastic Profile Extrusion Line,

Recyclable Plastic Granulation Line,

Plastic Powder Pelletizing Line ,

Plastic Pipe Winding Machine