Feeding Wheel

4 year ago

Polyurethane Lead Edge Feeding Wheel for Cardboard Printer

Feeding Wheel

improve the following disadvantages :

Paper feeding in the distorted direction

Low coefficient friction

Poor compressive modulus

Worn out of short life

Advantages of No-Crush Wheels during

*Polyurethane has the advantages of high rebound, super wear resistance and small permanent deformation, making it an ideal material for paper feeding wheels.

How does polyurethane compare with rubber in wear resistance?

Its wear resistance is excellent , about 3-5 times that of rubber. Under normal condition, it can use more than one year.

In general, it makes the wheel high wear resistance, high resilience, no damage to the paper and long service life.

Available Sizes , Also Welcome Custom

| Item Name | Product Picture | Standard specification |

|

Circular Lead edge Feeding Wheel

|

|

75*20 |

| 75*30 | ||

| 93*30 | ||

| 93*26 | ||

| 110*26 | ||

| 110*30 | ||

| Lead Edge Feeding wheel with 4 pillar |

|

75*20 |

| 75*26 | ||

| 93*26 | ||

| 93*30 | ||

| 110*26 | ||

| 110*30 | ||

| 102*26 |

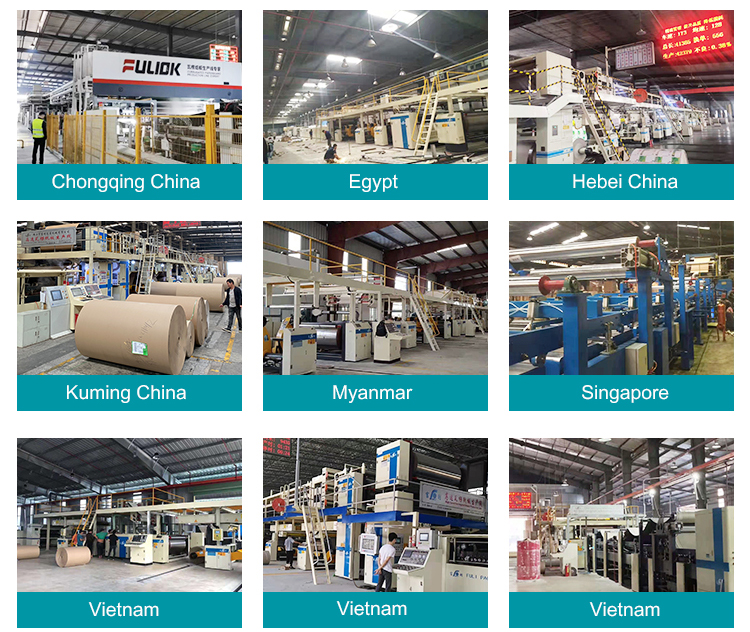

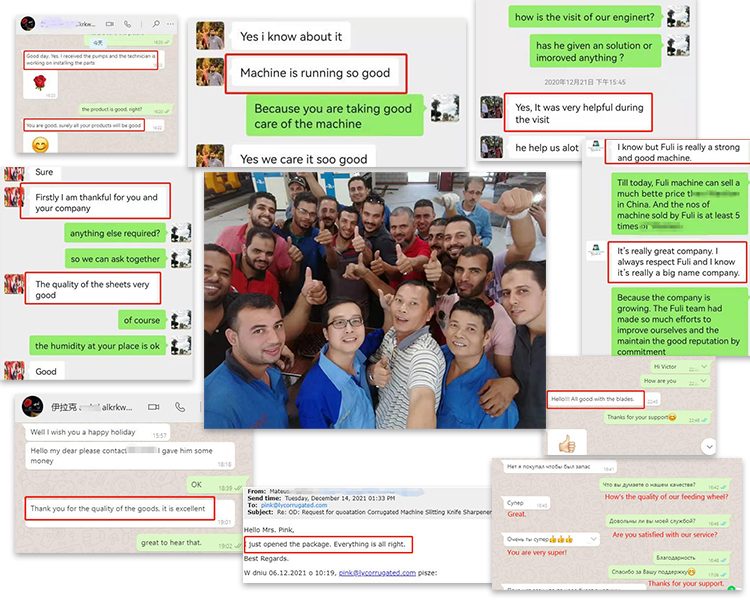

⭐So far, we are having more than 3500 sucessful installations of corrugated line all over the world.

A: Our factory is located in Foshan City, Guangdong Province, China.

For most of machines, engineers team provides solutions in the field of Mechanic/ Electric/ Operation.

TM online for 24 hours.

One year warranty period under normal use for most of machines.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- LLY PACK(foshan) Co.,Ltd.

- *Message:

-

Submit

Main Product:

Corrugated Line,

Single Facer ,

Corrugated Rollers,

Slitting Blades,

Double Facer Belt,

Printer Slotter Die Cutter