Ball type extracting and concentracting tank

4 year agoProduct Description

Main Feature of liquid mixing tank

Our compact work process and years of professional experience, enable us to offer you reasonable

price and perfect after sale service

|

Structure

|

Vertical, ellipse top or flat top, support by legs or lifting lugs. Single wall, or with jacket, or with insulation.

|

|

|

|

|||

|

Material

|

Material adopts S31603, or S304

|

|

|

|

|||

|

Jacket Type

|

Full jacket, internal coil, external semi-coil, dimple jacket.

|

|

|

|

|||

|

Insulation

|

Adopts aluminum silicate or polyurethane, thickness 50 mm or 75 mm.

|

|

|

|

|||

|

Surface Finishing

|

Mechanical polishing, internal mirror polishing Ra 0.45; External matte, Ra 0.8

|

|

|

|

|||

|

Heating Method

|

Steam heating, electric heating, thermal oil/hot water heating

|

|

|

|

|||

|

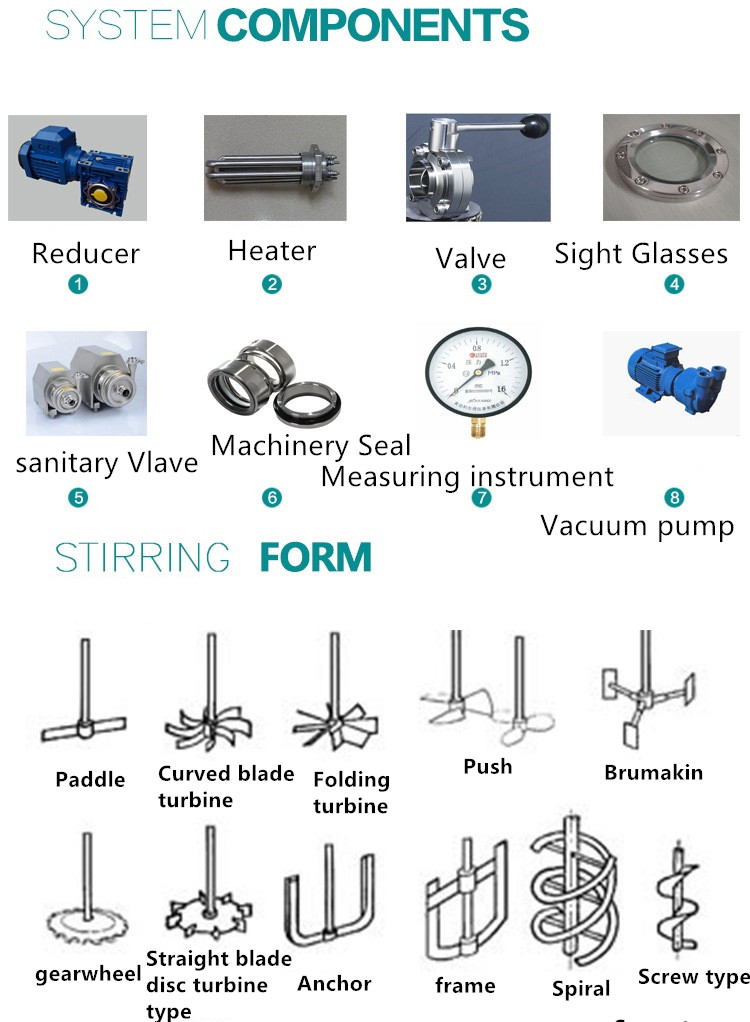

Agitation System

|

Adopt top center-entry agitator or side-entry agitator.

Agitator type: frame, anchor, paddle, turbine, spiral, screw, magnetic stirring. Agitation speed: 10~120rpm, fixed speed or frequency speed. Motor power: 0.55kw, 1.1kw, 1.5kw, 2.2kw, 3kw, 5.5kw, 7.5kw, etc. |

|

|

|

|||

|

Accessories

|

Manhole, CIP spraying ball, thermometer, piezometer, air filter, sight glass, light, counter flange.

|

|

|

|

|||

|

Standard

|

All according to GMP requirements and GB150.1~4-2011 Design, Fabrication, Inspection and Acceptance.

|

|

|

|

|||

|

ODM/ODM

|

Can be customized according to customers requirement and product process.

|

|

|

|

|||

|

Volume (L)

|

Core Dia.

(mm)

|

Jacket Cover

dia (mm)

|

Motorpower

(KW)

|

Working pressure (MPa)

|

Speed RPM

|

Vacuum (MPa)

|

Working temperature (℃)

|

|

30

|

400

|

500

|

0.6-1.1

|

homoeothermy

|

51-35

|

< - 0.09

|

0~100

|

|

50

|

500

|

600

|

0.6-1.1

|

homoeothermy

|

51-35

|

< - 0.09

|

0~100

|

|

100

|

550

|

650

|

1.1-1.5

|

homoeothermy

|

51-35

|

< - 0.09

|

0~100

|

|

150

|

600

|

700

|

2.2

|

homoeothermy

|

51-35

|

< - 0.09

|

0~100

|

|

200

|

650

|

750

|

2.2

|

homoeothermy

|

51-35

|

< - 0.09

|

0~100

|

|

300

|

2050

|

110

|

3

|

homoeothermy

|

51-35

|

< - 0.09

|

0~100

|

|

500

|

900

|

1000

|

4

|

homoeothermy

|

51-35

|

< - 0.09

|

0~100

|

|

800

|

1100

|

1200

|

5

|

homoeothermy

|

51-35

|

< - 0.09

|

0~100

|

|

1000

|

1200

|

1300

|

6

|

homoeothermy

|

51-35

|

< - 0.09

|

0~100

|

|

1500

|

1300

|

61400

|

4

|

homoeothermy

|

51-35

|

< - 0.09

|

0~100

|

|

2000

|

1400

|

1500

|

4

|

homoeothermy

|

51-35

|

< - 0.09

|

0~100

|

|

2500

|

1400

|

1500

|

7.5

|

homoeothermy

|

51-35

|

< - 0.09

|

0~100

|

|

4000

|

1500

|

1600

|

7.5

|

homoeothermy

|

51-35

|

< - 0.09

|

0~100

|

|

8000

|

2000

|

2100

|

15

|

homoeothermy

|

51-35

|

< - 0.09

|

0~100

|

|

32000

|

3000

|

2100

|

37

|

homoeothermy

|

51-35

|

< - 0.09

|

0~100

|

Company Profile

Certifications

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Wenzhou suote pharmaceutical and chemical engineering CO.,LTD

- *Message:

-

Submit

Main Product:

Stainless steel storage tank,

Stainless steel reactor,

Stainless steel pipe fitting,

Fruit and vegetable processing machinery ,

Colloid mill ,

filter system