Precision Mold Components

7 month agoAs a key guiding component in a mold system, how do Guide Sleeve used in application scenarios in different industries?

1. Automobile manufacturing industry:

Stamping molds: In the stamping and molding process of automobile body, chassis and other parts, the mold guide bush ensures accurate guidance between the punch and the mold, improving the dimensional accuracy of the stamped parts and the service life of the mold.

Plastic injection molds: Used in the production of automotive interior and exterior parts, parts of the injection mold, the guide sleeve to ensure that the moving mold and the fixed mold in the closing of the mold accurate alignment, to ensure the molding quality of plastic parts.

2. Electronics industry:

Precision injection molds: Used in the production of precision electronic components, such as connectors, housings, etc., the guide bushings to ensure high-precision guidance of the mold, to meet the size and functional requirements of electronic components.

Stamping molds: used for the production of circuit boards, metal frames and other components, the use of guide bushings to ensure the high precision and consistency of stamped parts.

3. Packaging industry:

Plastic Packaging Molds: Used in molds for the production of plastic bottles, lids, boxes and other packaging materials, the guide bush ensures the stability and accuracy of the mold during the closing process, which affects the appearance and quality of the packaged product.

4. Aerospace industry:

Composite molding molds: In the molding process of composite parts, the guide bush ensures precise guidance of the mold, which has strict requirements on the size and geometry of the parts.

Precision Parts Processing: In the precision processing molds for aerospace parts, the role of Guide Bushings cannot be underestimated, ensuring the high accuracy and reliability of the parts.

5. Medical device industry:

Precision parts injection molding: For making precise parts in instruments such as syringes, catheters and so on As for the high-precision guidance of mold, the guide sleeve guarantees the mold to reach the high standard requirement of medical instruments.

6. Furniture and Household Goods Industry:

Plastic product molds: The mould is for household products like plastic chairs, tables, storage boxes etc The guide sleeve will provide a steadier path and guide the mould ensuring easier, better and more consistent appearance quality.

7. Construction industry:

Door and window profile molds: Pivoted mainly from the architectural doors, windows, profiles, etc., The Drill Bit Guide Sleeve plays a significant role in guiding the mold during processing since its straightness as well as its size affects the overall product.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Dongguan Hao Chen Precision Industry Co., Ltd.

- *Message:

-

Submit

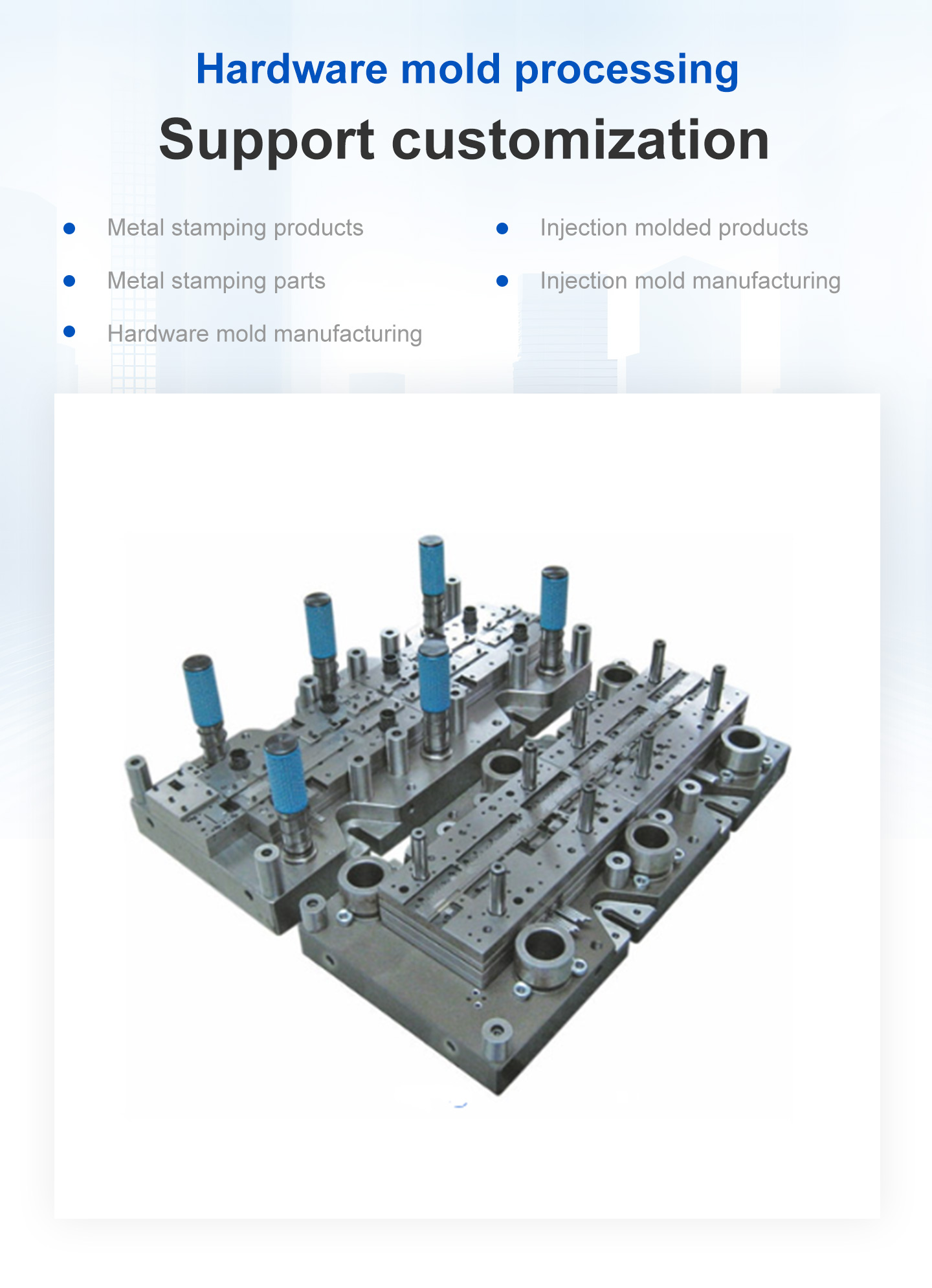

Main Product:

Hardware Mold,

Hardware Stamping Parts,

Injection Molded Products,

Carbide Punches,

Mold Parts,

Injection Mold Manufacturing

You May Also Like