Custom Injection Molded Products

7 month agoPrecision Non-standard Hardware Stamping Parts are those high-precision parts that do not have uniform standards in size, shape and performance, but are designed and manufactured according to specific applications or customer-specific requirements. These parts are usually used in industrial fields that have extremely high requirements for precision, material properties, surface quality, etc., such as aerospace, precision machinery, medical equipment, semiconductor equipment, optical instruments, etc.

What are the characteristics of Precision Non-standard Hardware Stamping Parts?

1. High precision: Precision non-standard parts have extremely high dimensional accuracy, with tolerances often in the micron or even nanometer range. This high precision ensures the accuracy and reliability of the parts in complex assemblies and precision operations.

2. Complex geometry: These Stamped Parts may have complex geometry, including irregular contours, deep holes, narrow slits, tiny features, etc., which require high-precision machining techniques and equipment to realize.

3. Special materials: Precision non-standard parts may be made of special materials, such as high-strength alloys, titanium alloys, stainless steel, ceramics, composites, etc., which have special physical, chemical, and mechanical properties to meet the needs of specific applications.

4. Customized production: Every Precision Non-standard Custom Sheet Metal Stamping Part is developed and built as per the actual application and for this, manufacturers need to possess profound designing skills along with capacity to produce custom made products.

5. Strict quality control: Non-standard parts used in manufacturing industries need to have a controlled production process in terms of part quality and accuracy such as material testing, dimensional testing, surface quality, and performance testing among others, to check if the parts being manufactured meet the design specifications and hence the intended application.

6. Various machining processes: Non standardized parts made for precise applications may be produced by any of the precision machining techniques such as turning, milling, grinding, EDM, wire cutting, laser cutting, ultrasonic cutting, precision casting, precision forging, etc, heat treatment and some specialized surface treatments.

7. Complex assembly requirements: Some non-standard parts may require to be assembled with other parts at whole manufacturing process is over and this takes high interchangeability and fit standards of the parts.

8. High cost and value: Precision non standard parts conventionally encompasses certain levels of dimensional accuracy that often call for high accuracy in precision manufacturing, thus, precision non standard parts normally cost much since they come with inherent high value inasmuch as they offer critical marginal utility in a given application.

The usage of Precision Non-standard Hardware Stamping Parts in high-precision industries demonstrates the modern industry’s trend of pursuing higher precision and functionality for parts and is a powerful driving force for scientific and technological progress and industrial transformation.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Dongguan Hao Chen Precision Industry Co., Ltd.

- *Message:

-

Submit

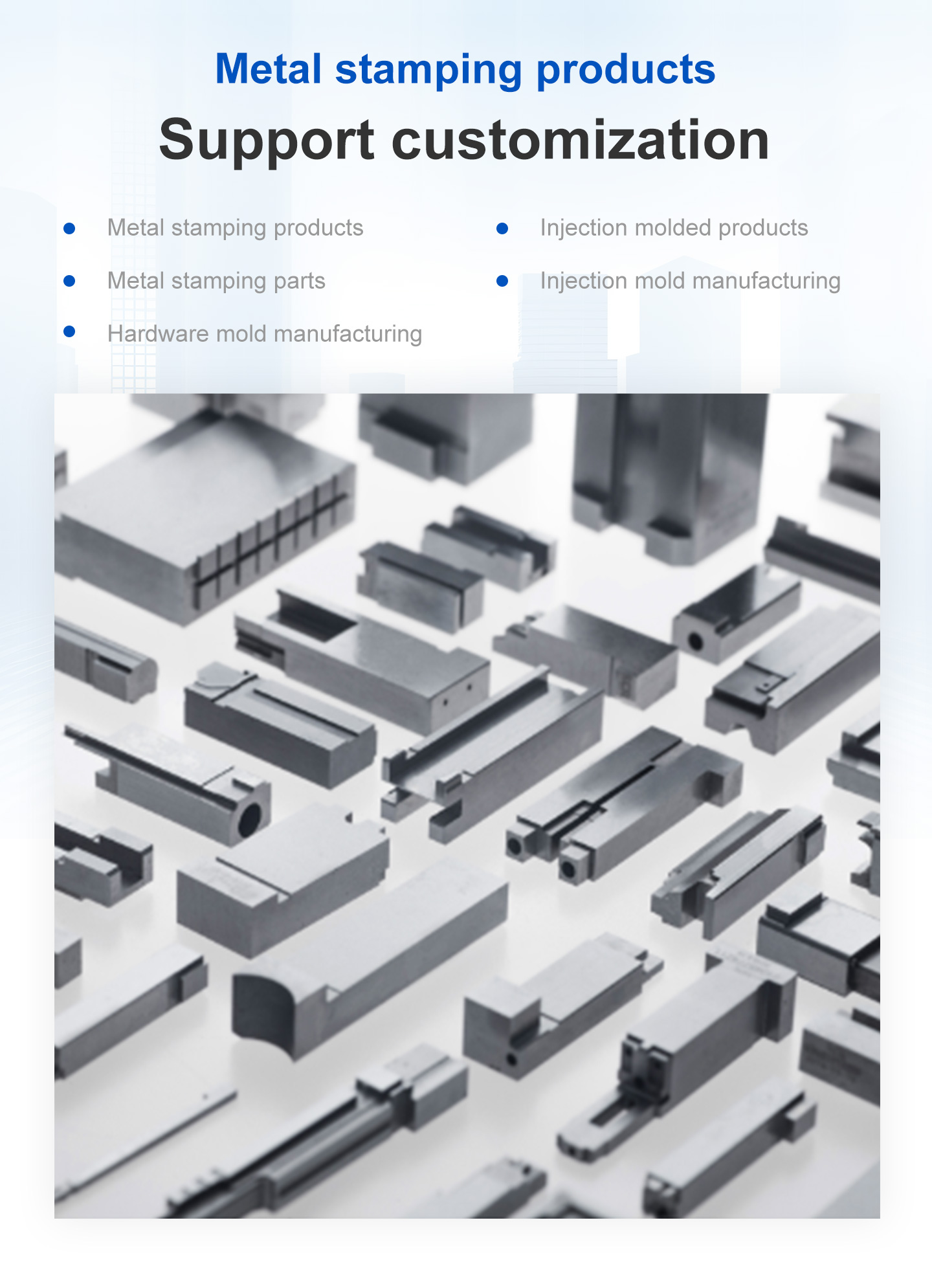

Main Product:

Hardware Mold,

Hardware Stamping Parts,

Injection Molded Products ,

Carbide Punches,

Mold Parts,

Injection Mold Manufacturing

You May Also Like