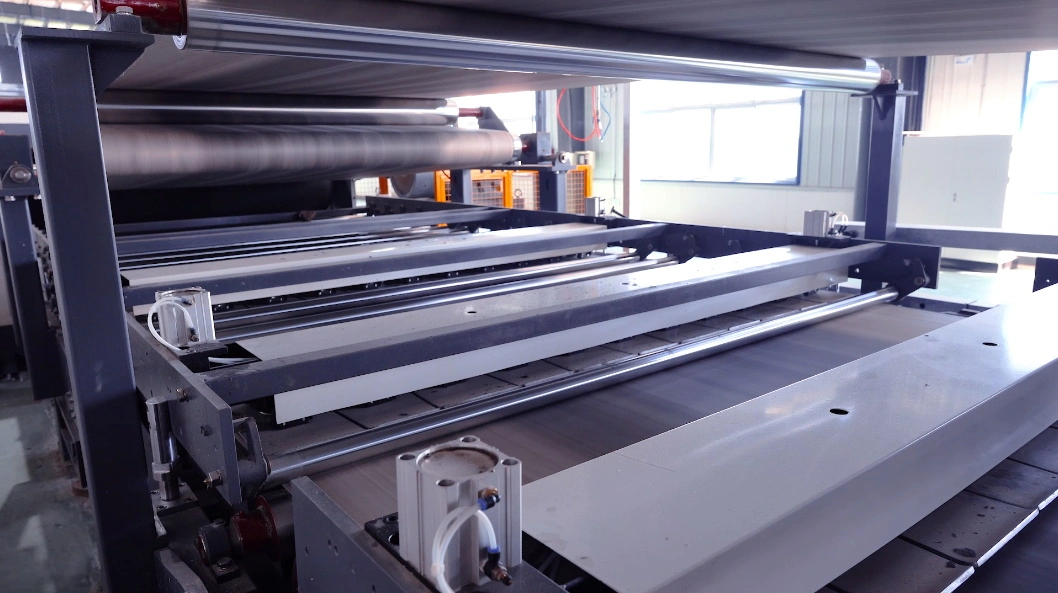

Double facer

5 month ago

* NOT out of shape - The Stand is in stacked frame with H iron and is equipped underframe

* Overhead canvas belt supporting type* Suit for cardboard of different thickness - the pressure roller is equipped with power system to adjust the height.

* Four phrase to adjust the pressure of roller according to cardboard's thickness and material

* Hydraulic lifting mechanism is internal mounted

* Belts with auto deviation adjusting mechanisms

* The operating surface and the heating plates are ground,and plated with hard chromium

* Heating exchange evenly - The hot plates are double in-and-out type, with the internal labyrinth structure

* Stable Temperature- the heating plate adopt the higher chamber,which storage more heat

* All Rollers are wearable and rust-resisted

Pressuring plates of the cylinder: Advised QTY:4,6,10+2/ PCS

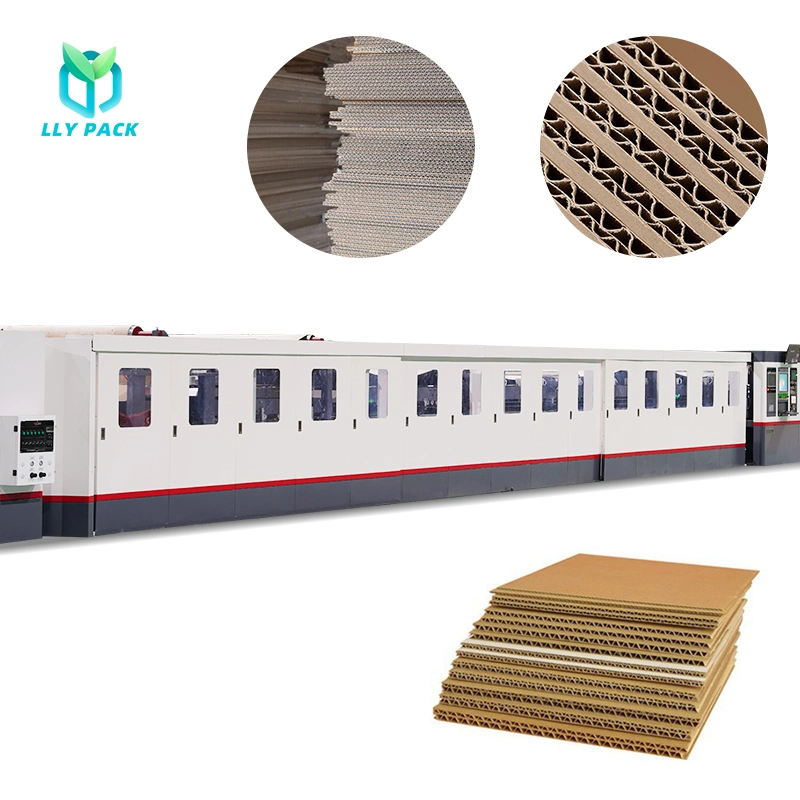

The new type of energy-saving tube hot plate with the rapid speed lifting system.

DFC External Dimensions And Whole Machine Power

|

Paper Width(mm)

|

External Dimensions(L*W*H))

|

Weight(T)

|

Total Power of Motor(KW)

|

|

1400

|

21000*2320*2160

|

38

|

4

|

|

1600

|

21000*2520*2160

|

40

|

4

|

|

1800

|

21000*2720*2160

|

42

|

4

|

|

2000

|

21000*2920*2160

|

44

|

4

|

|

2200

|

21000*3120*2160

|

46

|

4

|

|

2300

|

21000*3220*2160

|

47

|

4

|

2. Overhead canvas belt supporting type, with two sets of upper canvas belt tensioning mechanisms; Concealed oil hydraulic lifting mechanism;

3. The operation side is protected with a closing plate, so it is beautiful and safe;

4. Both the upper and lower canvas belts are provided with automatic deviation adjusting mechanisms;* The lower canvas belt tensioning mechanism is installed vertically to be easily adjusted;

5. The pressure roller is equipped with a power system to adjust the height so as to meet the requirements for different

thicknesses of cardboard;

6. The operating surfaces of the heating plates are ground, and plated with hard chromium, and the heating plates meet the China national standard for Class l pressure vessels; all heating plates are attached with pressure vessel inspection certificate, etc.;

7. The steam pipes are arranged reasonably to realize grouping temperature adjustment for the heating plates.

8. The gas supply of hot plate is double in and double out, which makes the heating transfer more rapidly.

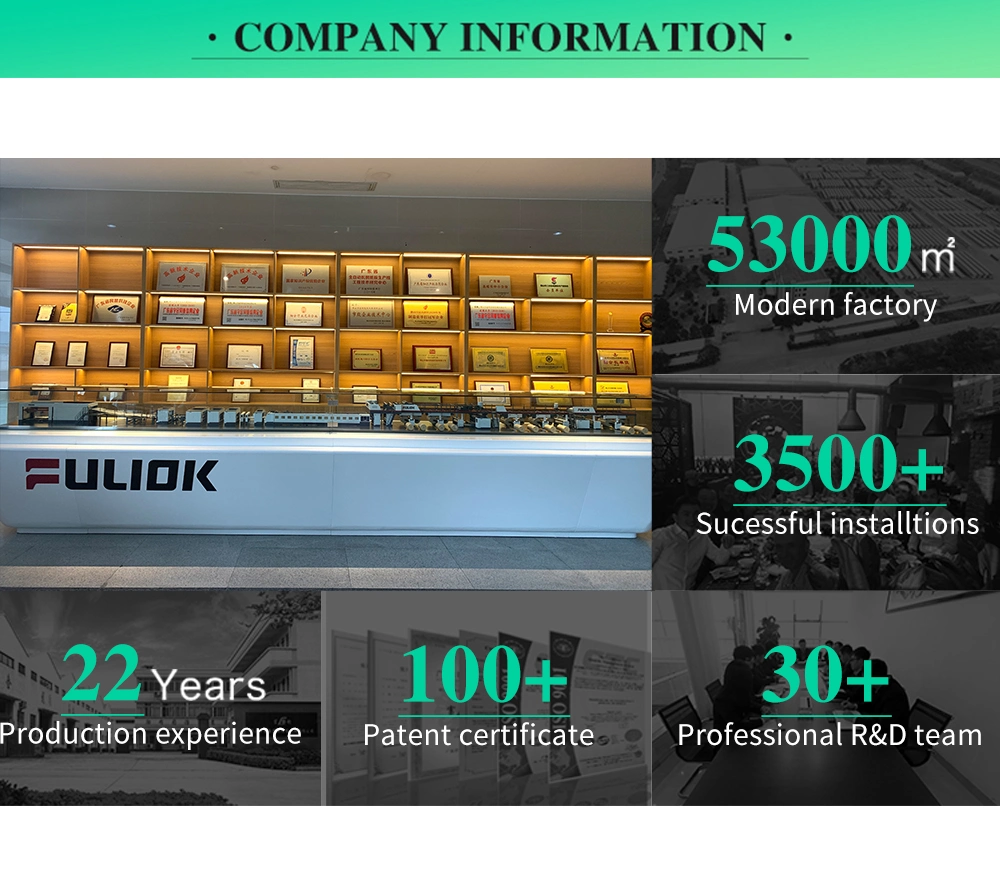

A: We are a manufacturer, located in National High-tech Industrial Zone, Sanshui, Foshan City, Guangdong Province, China. Warmly

welcome to visit our company.

2. Q: What is your minimum order quantity, can you send me samples?

A: Our minimum quantity is 1 set.

With over 3500+ sucessful installation experience in the last 22 years, we provide tailor-made solutions as per customer's demand.

3. Q: How does your factory do regarding quality controlling?

1). 22 Years of Specialization in Corrugated Industry Solutions that delight

2). Over 3500+ successful installation corrugated cardboard production line

3). Quick Responsive Professional Pre-sales Service

4). Top machinery R&D team

5). A state-of-the art factory with full set up of manufacturing facilities, including 4 Sets of advanced 5-face High Precision

CNC Center

6). Strict inspection before delivery

7). All-round after-sales Service System

8). Fuli is the unique company who drafts the latest version of national industry standard for corrugated machines in China

4. Q: How about the after-sale service?

All-round after-sales Service System

Engineers team provides solutions in the field of Mechanic/ Electric/ Operation.

TM online for 24 hours.

Online Quick Responsive service: Email, skype, MSN, Facebook, Linkin, Whatsapp, Instangram.

One year warranty period under normal use for machines.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- LLY PACK(foshan) Co.,Ltd.

- *Message:

-

Submit

Main Product:

Corrugated Line,

Single Facer ,

Corrugated Rollers,

Slitting Blades,

Double Facer Belt,

Printer Slotter Die Cutter