dc6f710a9aba98fbdbb83749fd279c6e

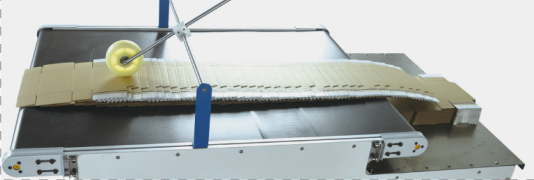

8 month agoJYX-1450 Automatic double side tape applicator

|

Material : |

More than 200g/m² of cardboard -8mm corrugated board |

|

Paper size: |

min. 100 mm x 100 mm |

|

max.1450 mm x 850 mm |

|

|

Working width: |

1500 mm |

|

Conveyor speed : |

90m/min (Speed depends on paper material box type) |

|

Tape roll width : |

5 – 40 mm |

|

Precision: |

+ / -1.5mm |

|

Sticking style: |

Longitudinal gluing |

|

Number of installable tape applicators: |

2 sets of double-sided adhesive applicators (2 heads) |

|

Needed air supply : |

min. 6 bar |

|

Power required: |

3.2 KW(380V AC 3φ 50HZ) |

|

Automatic continuous paper feed |

|

|

Weight: |

1300KG |

|

Machine Size : |

4500*1900*1200mm(L*W*H) |

(Term)

Quality Expiration: 1 year (without wearing parts)

Package: Standard Package

Installation and training: 3 days for installation and training

Lead Time:20days after contract and deposit.

Payment:30% down payment after signing contract, 60% before shipment and balance.

This Double Side Tape Applicator is a new designed machine special for double side tape sticking with technical from Germany. High efficient, high precise and high stability are its features. It can set the length and sections of double side tape freely. The highest speed is 90m/min. This model is aimed at cardboard, corrugated board which need double side tape. The designation is easy for adjustment and operation. This is your best choice for double side tape sticking.

Feeder Section

There are 7pcs 35mm width belt. The vibration motor combines bottom feeding automatically. Embossing roller guides the feeding belt. Left and right block can be adjusted due to the products’ size. Two pieces feeding knife drove by individual motor to adjust the feeding distance.

Sticking Table

Sticking table use lengthen platform and deliver the products on conveyer belt. Separately adjust the presser and sticking equipments. Double side tape part can be adjusted front/back or left/right without turning off the machine.

The screen can show all the information. This can make the parameter setting and operating for easily and conveniently. Position tracking uses optical fiber technology which makes it more precise and function stable.

Applicator head is import component. KS controller use DSP high speed calculating and FPGA drive control technology. High efficient and timely tracking design. It can make sure the high precise in high speed running. The controller is very flexible and very easy to be set. The quality, stability and reliability are more than other similar machines.

Conveyor Section

The 2mm thickness belt (import from Germany) is soft enough for protecting products from pressing damage. Stack collection structure perfect the products quality. There is a products counting option.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Anhui Innovo Bochen Machinery Manufacturing Co., Ltd.

- *Message:

-

Submit

Main Product:

flute laminating machine,

pile turner ,

litho laminating machine ,

gift box making machine,

book case making machine,

flip flop machine

You May Also Like