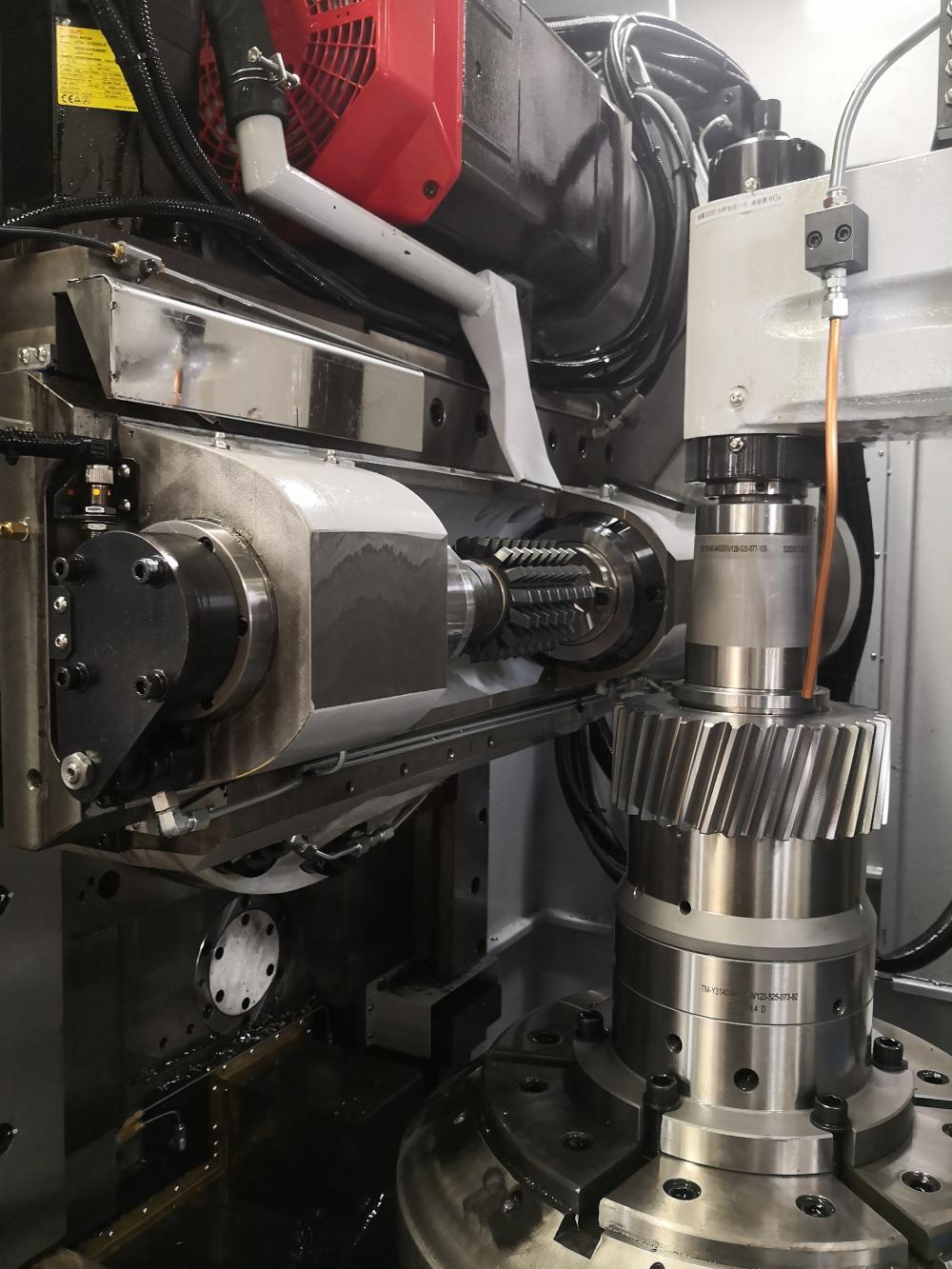

gear hobbing

3 year ago

Y3150 CNC6

a versatile hobbing machine suited for large sized gears

A powerful 6 axis full CNC hobbing machine

An extremely rigid hobbing machine

FANUC numerical control system and servo drive, system reliability, simple operation

Wet Cutting Hobbing Machine

Max. Workpiece Diameter: Φ500 mm

Max. Module: 10/12

cnc high-precision large gear hobbing machine for sale :

1)The full CNC system has 6-axis and 4 linkage, use generating method, realized indexing and differential compensation movement with CNC electronic gear box function, it can finish the cylindrical spur gear, helical gear and small taper tooth, drum gear, spline, worm gear, sprocket and so on tooth process .

Main Technology Parameter

|

CNC hobbing machine |

Unit |

TMY3150 |

|

|

|

Wet hobbing |

|

Max. workpiece diameter |

mm |

Φ500 |

|

Maximum module |

mm |

10/12 |

|

Worktable surface diameter |

mm |

Φ450 |

|

Hob Maximum Assemble DiameterX Length |

mm |

Φ170/Φ 240x300 |

|

Horizontal distance between hob center and worktable center |

mm |

45-375 |

|

Maximum hob axial movement amount |

mm |

180/200 |

|

Hob head slide travel (Z axis movement amount) |

mm |

200-600 |

|

Maximum swiveling angle of the hob head |

Deg |

±45° |

|

Hob spindle motor power |

KW |

15 |

|

Maximum hob spindle rotate speed(B axis) |

rpm |

500/750 |

|

Maximum worktable rotate speed(C axis) |

rpm |

75 |

|

Radial feed speed (X axis)(stepless) |

mm/min |

1-2000 |

|

Radial maximum rapid move speed(X axis) |

mm/min |

5000 |

|

Axial feed speed(Z axis)(stepless) |

mm/min |

1-2000 |

|

Axial maximum rapid moving speed(Z axis) |

mm/min |

6000 |

|

Tangential feed speed(Y axis) (stepless) |

mm/min |

1-1000 |

|

Radial maximum rapid travel speed(Y axis) |

mm/min |

2500 |

Standard Configuration

|

Hob arbor assembly ( Φ40) |

hydraulic system |

|

Hob arbor automatic clamping device |

NC controller system |

|

Workpiece automatic clamping device |

NC data memory card |

|

Spindle positioning |

Operational software |

|

Fully-enclosed safeguards |

Residual-current circuit breaker |

|

Woking light |

Hands action button |

|

Three colour lights indicate machine status |

RS232C connector |

|

Workpieces counter |

Air conditioner for electric cabinet |

|

Main spindle ampere meter |

Chip conveyor |

|

Chip cart |

Automatic lubrication system |

|

Cutting oil tank |

Mist collector |

|

Cold spray gun |

The sizing block for machine adjustment |

Optional Configuration

|

Automatic loading/unloading material device |

Workpiece clamping |

|

Automatic material storage |

Workpiece rough locator device |

|

Deburring device |

Automatic tooth align device |

|

Independent hob adjustment device |

Oil cooling device |

|

Hob arbor assembly:(metric system:Φ22, Φ27, Φ32, Φ50, Φ60),(Inch system: Φ26.988, Φ31.75, Φ38.1, Φ50.8) |

|

Application

Construction Machine Gear

Marine Gear

Large Reduction Gear

Wind Power Generator Gear

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Zhejiang Toman Intelligent Technology Co., Ltd

- *Message:

-

Submit

Main Product:

Gear Hobbing Machine,

Gear Shaving Machine,

Gear Automatic Production Line,

Gear Cutting Machines,

Gear Hobbing/Chamfering Compound machines ,

Bearing Turning Machine

You May Also Like