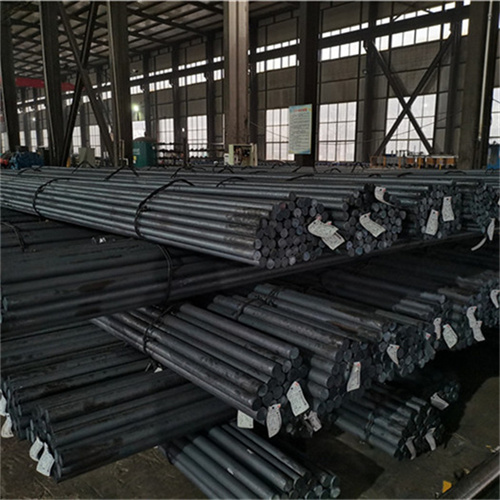

Factory real shot

3 year agoHot Rolled AISI/SAE 4340 Alloy Steel Round Bar

AISI 4340 steel is a medium carbon, low alloy steel known for its toughness and strength in larger sections. AISI 4340 is also a nickel-chromium-molybdenum steel. 4340 has higher strength, ductility, toughness, creep resistance and fatigue resistance than most other steels. The alloy achieves a high degree of hardenability, with HRC hardness ranging from 24 to 53, depending on heat treatment. High toughness and strength in the heat-treated state.

Alloy 4340 steel is usually hardened and tempered in the tensile range of 930 – 1080 Mpa. Pre-hardened and tempered 4340 steel can be further case hardened by flame or induction hardening and nitriding. 4340 steel has good impact and impact resistance as well as wear and abrasion resistance in the hardened state. AISI 4340 steel has good ductility in the annealed condition and can be bent or formed. ASTM 4340 materials are typically used where other alloy steels do not have the hardenability to provide the required strength. It is an excellent choice for high stress parts. AISI 4340 alloy steel can also be machined by all conventional methods.

For 4340 steel grade materials, we can supply you aisi4340, sae 4340, astm 4340 hot rolled steel round bar, aisi 4340, sae 4340, astm 4340 cold drawn steel round bar, aisi 4340, sae 4340, astm 4340 peeled steel round bar, aisi 4340, sae 4340, astm 4340 centerless ground and polished steel bar, sae 4340, aisi 4340, astm 4340 annealed, normalized, quenched and tempered steel round bar.

Specification of 4340 ground and polished steel bar we supply:

1. 4340 steel equivalent material:

|

GB |

JIS |

ASTM/AISI/SAE |

|

40CrNiMo(A) |

SNCM439 |

4340 |

2. 4340 steel Chemical composition:

|

|

C |

SI |

MN |

S |

P |

Cr |

Mo |

Ni |

|

40CrNiMo(A) |

0.37-0.44 |

0.17-0.37 |

0.50-0.80 |

0.035 (max) |

0.035 (max) |

0.60-0.90 |

0.15-0.25 |

1.25-1.65 |

|

SNCM439 |

0.36-0.43 |

0.15-0.35 |

0.60-0.90 |

0.030 (max) |

0.030 (max) |

0.60-1.00 |

0.15-0.35 |

1.65-2.00 |

|

aisi 4340 |

0.38-0.43 |

0.15-0.35 |

0.60-0.80 |

0.035 (max) |

0.035 (max) |

0.70-0.90 |

0.20-0.30 |

1.65-2.00 |

3. 4340 steel Mechanical Properties:

|

Yield Strength(MPa) |

Tensile Strength(MPa) |

Elongation(%) |

AKV |

|

835(min) |

985(min) |

12(min) |

55(min) |

Note: The mechanical properties can be adjusted according to heat treatment based on your requirement.

4. 4340 steel applications:

AISI 4340 steel is used in most industrial sectors for applications requiring higher tensile/yield strength than 4140 steel.

Some typical applications are: aircraft landing gear, automotive, oil and gas drilling, forging, hot and cold forming, machine building, transmission systems such as power transmission gears and shafts.

General engineering industry and structural use applications such as: heavy duty shafts, gears, axles, spindles, couplings, pins, chucks, molds, etc.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- SHANDONG LE REN SPECIAL STEEL CO., LTD.

- *Message:

-

Submit

Main Product:

Cold Drawn Steel Bar,

Bright Steel Bar,

Heat Treated Steel Bar and Tube ,

Threaded Rods,

High Strength Steel Tie Rod,

High Strength Steel Bolts

You May Also Like