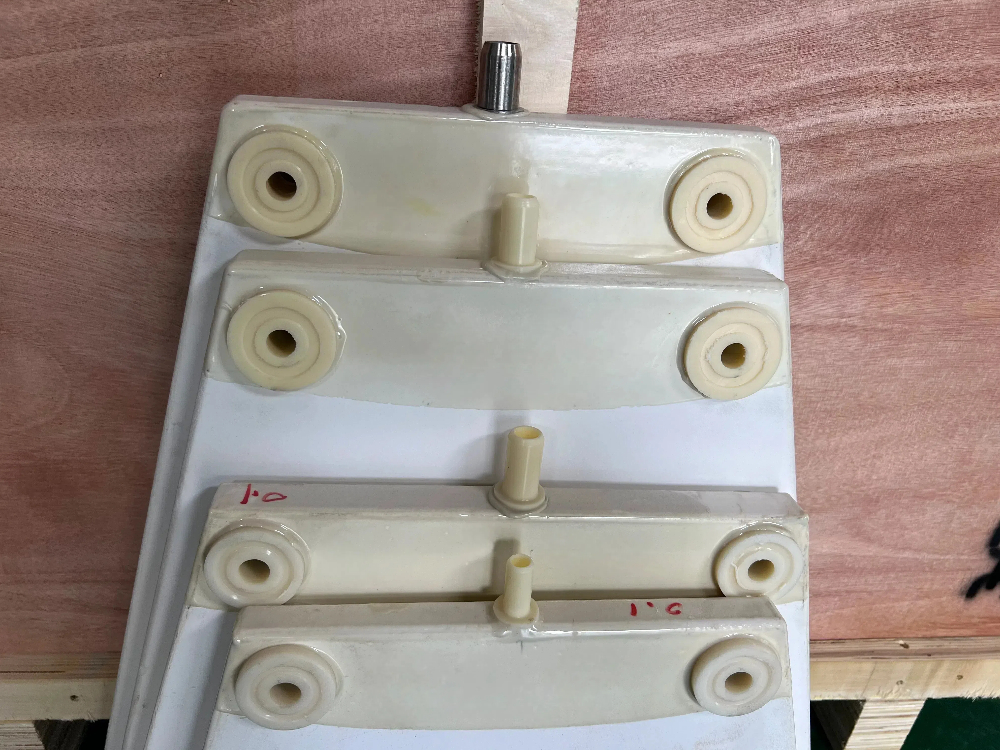

Ceramic Filter Plate

4 month ago

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Rongxin Environmental Protection Equipment Co., Ltd.

- *Message:

-

Submit

Main Product:

Ceramic Filter Plate,

Ceramic Filter,

Ceramic Scraper ,

Ceramic Vacuum Filter,

Dynamic Rotate Ceramic Membrane,

Gasification Equipment

You May Also Like