PVC machine loading .mp4

5 year ago

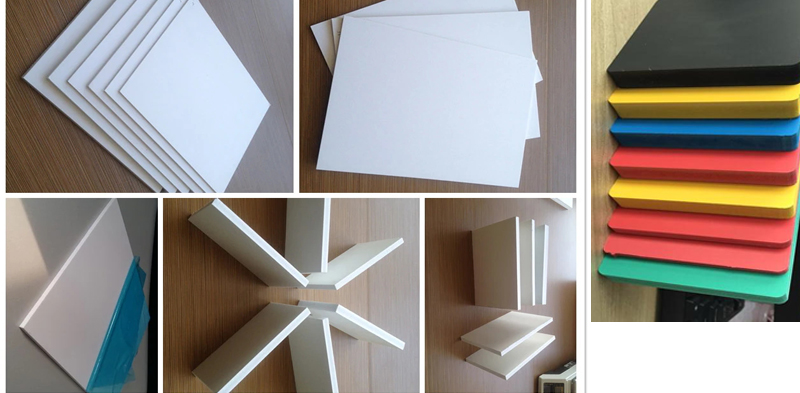

PVC/WPC Foamed Board Extrusion Line

PVC WPC Surface Crust Foamed Board Production Line/PVC WPC Plastic Building Templates Board Machine

Product size: width: 1220mm/thickness: 3-30mm

Main Material: PVC Compounding , processing additives and filling agent

Extruder: SJSZ80/156 conical double screw extruder

Output: 300-400kg/hour

Cooling water temperature: <15℃ ; Air pressure: > 0.6Mpa

Power supply: 3P/380V/50HZ or customized

Adopt the latest foam technology , and special design the screw & extrusion mould , it ensure the high efficiency foam , quickly calibration , it make the foam board surface more shine & hard than the traditional normal technology .

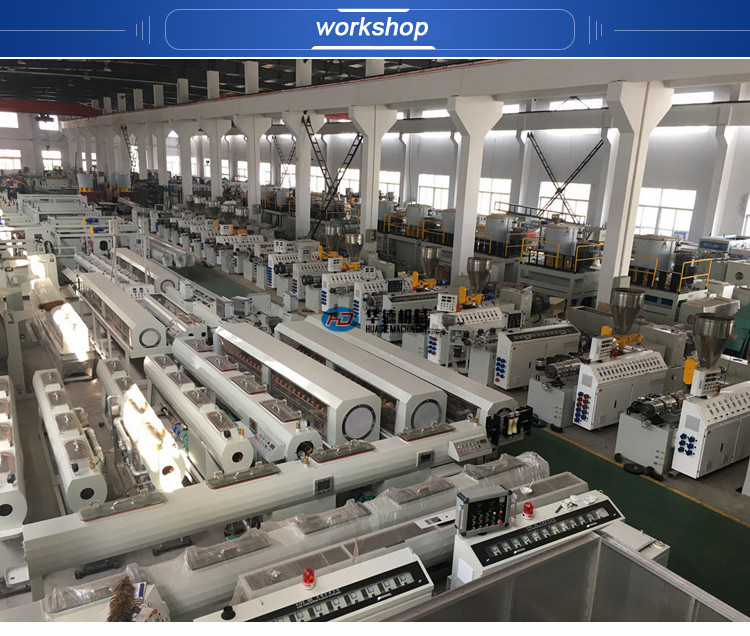

The complete production line consist of conical twin screw extruder , extrusion mould , vacuum calibration mould , roller hauling off machine , automatic cutter.PVC/WPC foam board Application:

Advertising decoration, solvent printing, display plate, silk-screen, computer lettering, sign plate, light box and ect.

Construction decoration, inner and outer decorate panel, commercial decorating shelf, room separating panel, roof decorating panel, cabinet, bathroom, cabinet roof and ect.

Carriage and roof canopy, carriage inner layer, inner decoration panel and other industry.

Twin screw extruder

High speed extrusion with high capacity and lower power consumption

Barrier design screw with asymmetric slotted barrel design.

PID simple automatic temperature control systems

﹡Screw and barrel material:38CrMoAlA,nitriding treated

﹡adopt original famous electric components with high steady running quality . Eg:

RKC or Omron temperature controller、ABB speed regulator、low-voltage breaker adopts Schneider or Siemens

﹡Gearbox adopt high torque, low noise, hard gear tooth face gear box

﹡Self protective system:

* current of motor overload automatic stop protection

* screw displacement automatic stop protection

* Lubrication oil starvation automatic alarm device

Die Head & Calibrator

1. clothes-rack channel design, which can minish ablation during extrusion and Inside and outside is chromeplated.

2. Adjustable upper die lip which can be changed with vertical restrictor bar control, in order to satisfy different thickness of product.

3. Mould is heated by heating bar

4. Lip of mould is heated by heat conducting oil

5. Die firmware use 12.9 grade high strength screw, adjusting bolt and mould are made of 40Gr.

6. Material of mold: 5CrNiMo

7. Material of forming mould: 5CrNiMo, chrome plated and polished

8. Thickness and width of board: 3-18mm and 1220mm / 18-30mm and 1220mm

Vacuum Calibration & Cooling Table

Action for open and close: hydraulic drive

Lift up and down table:electrical motor drive

Forward and backward movement: hydraulic drive

Cooling medium: cold water

Cooling table size: 1500*600*80mm

Material of mold: 5CrNiMo

Air Cooling Bracket

Length: 4000mm

Material: stainless steel piping

Cooling method: by air

8 Roller Haul Off Machine

Haul-off roller quantity: 8 pairs

Material of roller: rubber

Haul-off Motor Power:5.5KW*2PCS

Motor drive: ABB Inverter

Roller lift and down: cylinder pneumatic

Haul-off Speed:0.1~1 meter/min

Cutting Machine

Saw Diameter:Φ400mm

Cut Motor Power:4KW

Bracket Lengthways Move Distance:500mm

Sawdust Absorb Vortex Fan: 3KW

Control ways: Delta PLC control

WPC PVC Board/Panel surface treatment machines hot stamping machine

Auxiliary machines for PVC/WPC Foamed Board extrusion line

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Zhangjiagang Huade Machinery Technology Co.,Ltd

- *Message:

-

Submit

Main Product:

PVC pipe manufacture machine ,

PE pipe making machine ,

PPR pipe extrusion line ,

wall panel production ,

ceiling manufacture,

3 layer PVC tube machinery

You May Also Like