pet prefrom injection molding machine

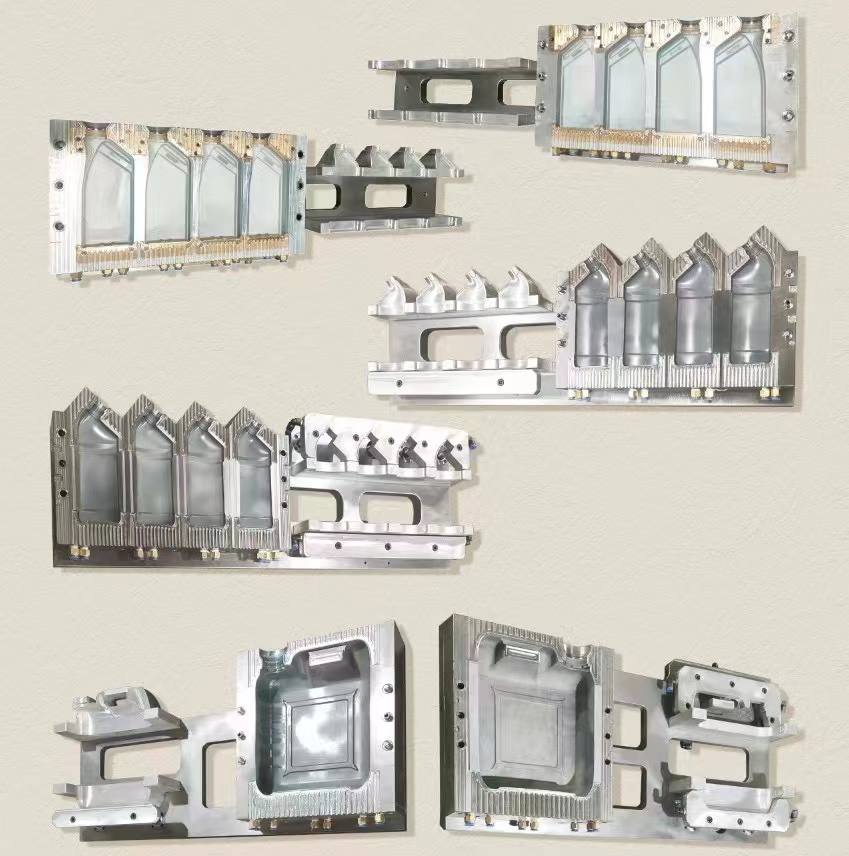

3 year agoHDPE and PE blow mold

The design and manufacture of blow molding molds with fast cycles and long service life are required by the development of the blow molding industry. The factors that determine mold efficiency include: 1) material: 2) cooling: 3) blank cutting edge design; 4) Exhaust.

The material used to make the mold must have high thermal conductivity and sufficient cutting edge strength. Currently, aluminum 70/75 is a high-grade alloy used for making most molds. Due to the good machining performance of this metal, the mold cavity is usually machined. The copper alloy mold also has high heat transfer and good corrosion resistance. However, due to its high cost and price, as well as its proportion three times that of aluminum, it may suffer severe wear and tear on molding machinery. The steel alloy mold is easy to repair by welding or inlaying.injection blow molding machine mold .

The thermal conductivity of cast aluminum molds is worse than that of cutting aluminum molds. The cutting edge of the mold cavity usually requires a broken copper alloy or stainless steel inlay, because the strength and hardness of cast aluminum cannot meet the requirements of the cutting edge blade.".

Kirk alloy (zinc) castings can be made on a steel master mold. The mold cavity and bottom plate are poured to a predetermined size. Due to insufficient strength of Kirk alloy

Cut the plastic, and the operating hole and shoulder area are inlaid with copper alloy or stainless steel. The bottom and neck are also inlaid with these two metals. Casting molds can also be used.PE blow mold .prefrom mould.

The casting is made of copper alloy. Casting by steel mold cavities is easier because it relies on pressure or gravity casting. Many of these cavities are made of steel master molds or

Fine components produced by ceramic pe blow mold.

Cooling plays a challenging and very important role in mold design. Drilled cooling pipelines are installed where cooling is most needed. For better production control, most molds are designed with several independent cooling zones. The neck and bottom require the most heat to be removed, and therefore require the most effective cooling.injection blow molding mold .

Cutting edge. The design depth of the cutting edge area can be a significant factor in component production and quality. The cutout area is an excess of plastic during component injection blow molding machine mold .

A place to enter. The type and shape of the cutting edge may determine the welding condition of a component.blow mold

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Ningbo Chenwei Machinery Technology Co.,Ltd

- *Message:

-

Submit

Main Product:

Injection Molding Machine ,

Blow Molding Machine ,

Plastic Mold ,

Blow Mold ,

Auxiliary Equipment ,

Vertical Injection Molding Machine