Peek plastic parts for sale

3 year agoPlastic Gear High Performance Engineering PEEK Parts High performance engineering plastic

PEEK Product

Application of PEEK material in gear PEEK gears help reduce vibration, noise and harshness stress

PEEK material is increasingly used as an alternative solution to traditional metal components in a variety of applications, including high-performance gear applications. This is mainly due to its unique mechanical properties, chemical resistance, wear resistance, fatigue resistance and ultra-high heat resistance up to 260°C.

The main advantages of PEEK gears compared with metal gears:

Weight loss up to 70%

Noise reduction up to 50%

Reduce moment of inertia by up to 80%

All why choose PEEK gear?

Significant weight reduction reduces energy consumption

Extended design options and high damping capacity for high comfort, less vibration and noise

No loss of strength or swelling due to moisture absorption

Reduced moment of inertia results in improved responsiveness

High corrosion resistance, extremely low friction and wear, and minimal lubrication extend service life and service intervals

Excellent resistance to oil particulate contamination, chemicals and all known automotive fluids allows the material to be used in the most challenging environments

In addition to gears, we can also customize PEEK bushings/special-shaped parts/processed parts and many high-temperature, low-temperature, and corrosion-resistant plastic accessories. Our engineers have more than 15 years of experience. The world's best supplier of engineering plastic accessories, the fastest 3 minutes The quotation will be shipped within 7 days, welcome to consult customer service for more information

|

Property |

Item no. |

Unit |

PEEK-1000 |

PEEK-CA30 |

PEEK-GF30 |

|

1 |

Density |

g/cm3 |

1.31 |

1.41 |

1.51 |

|

2 |

Water absorption(23℃ in air) |

% |

0.20 |

0.14 |

0.14 |

|

3 |

Tensile strength |

MPa |

110 |

130 |

90 |

|

4 |

Tensile strain at break |

% |

20 |

5 |

5 |

|

5 |

Compressive stress (at 2% nominal strain) |

MPa |

57 |

97 |

81 |

|

6 |

Charov impact strength(unnotched) |

KJ/m2 |

No break |

35 |

35 |

|

7 |

Charov impact strength(notched) |

KJ/m2 |

3.5 |

4 |

4 |

|

8 |

Tensile modulus of elasticity |

MPa |

4400 |

7700 |

6300 |

|

9 |

Ball indentation hardness |

N/mm2 |

230 |

325 |

270 |

|

10 |

Rockwell hardness |

-- |

M105 |

M102 |

M99 |

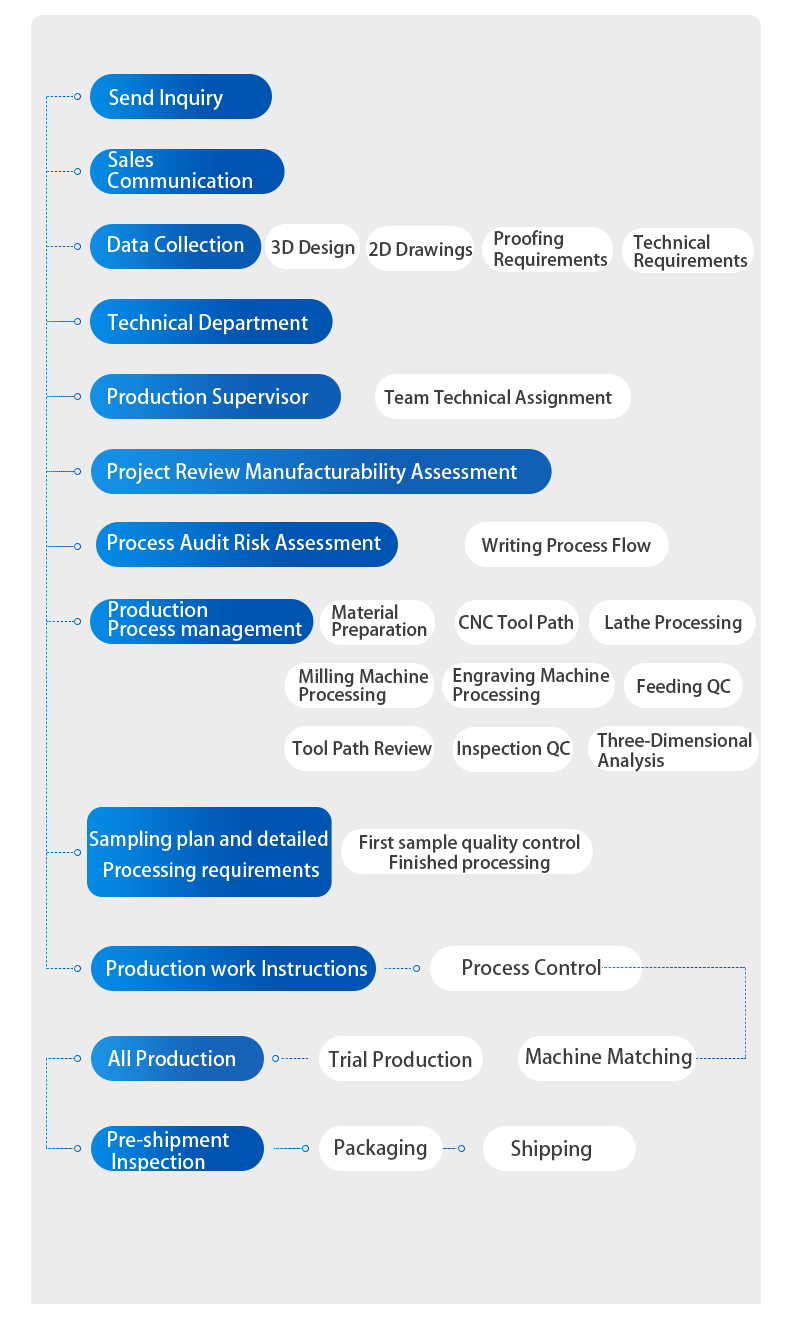

Our Factory

The factory covers an area of 10,000 square meters Production equipment has the original American imported Haas CNC machining center, wire-electrode cutting, electrical discharge machine,Perforating machine, injection molding machine, CNC milling machine CNC hobbing machine, CNC lathe, CNC milling machine CNC lathe, CNC milling machine, grinding machine and other machinery and equipment.

Companies strictly enforce the ISO9001(2008)international quality certification system, the product quality conforms to the eu RoHS standard.

For CNC machining, the products will be sent for 3 days. And we support OEM and ODM.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Guangzhou One-Stop Engineering Plastics Industries (group) Co., Ltd

- *Message:

-

Submit

Main Product:

CNC Machining Parts,

Injection Molding Parts,

Plastic Sheets ,

Plastic Tubes,

Plastic Rods,

Peek Sheet

You May Also Like