Assembly of brazed plate heat exchangers

2 year ago

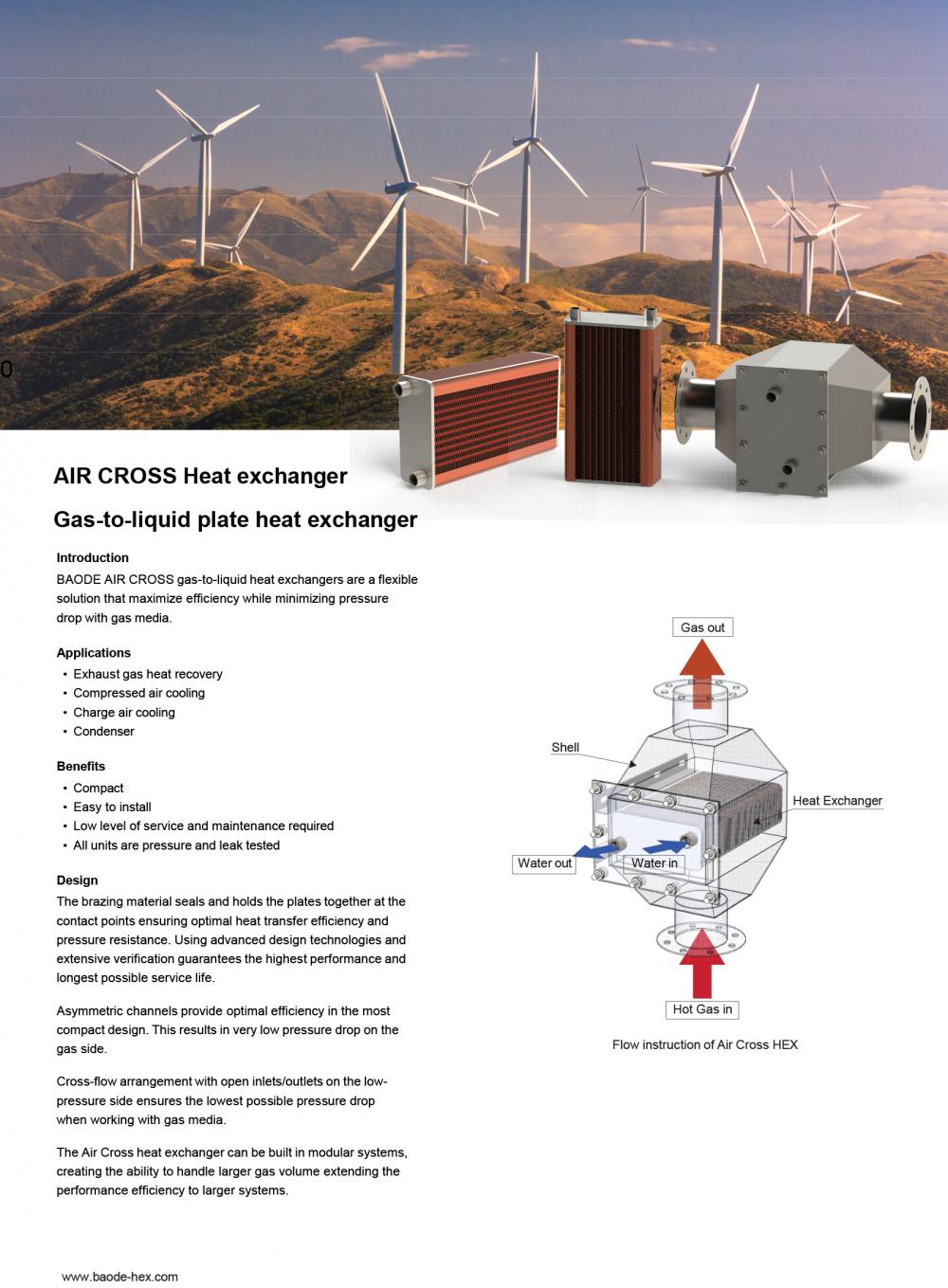

Exhaust Gas Heat Recovery Air Cross Heat Exchanger

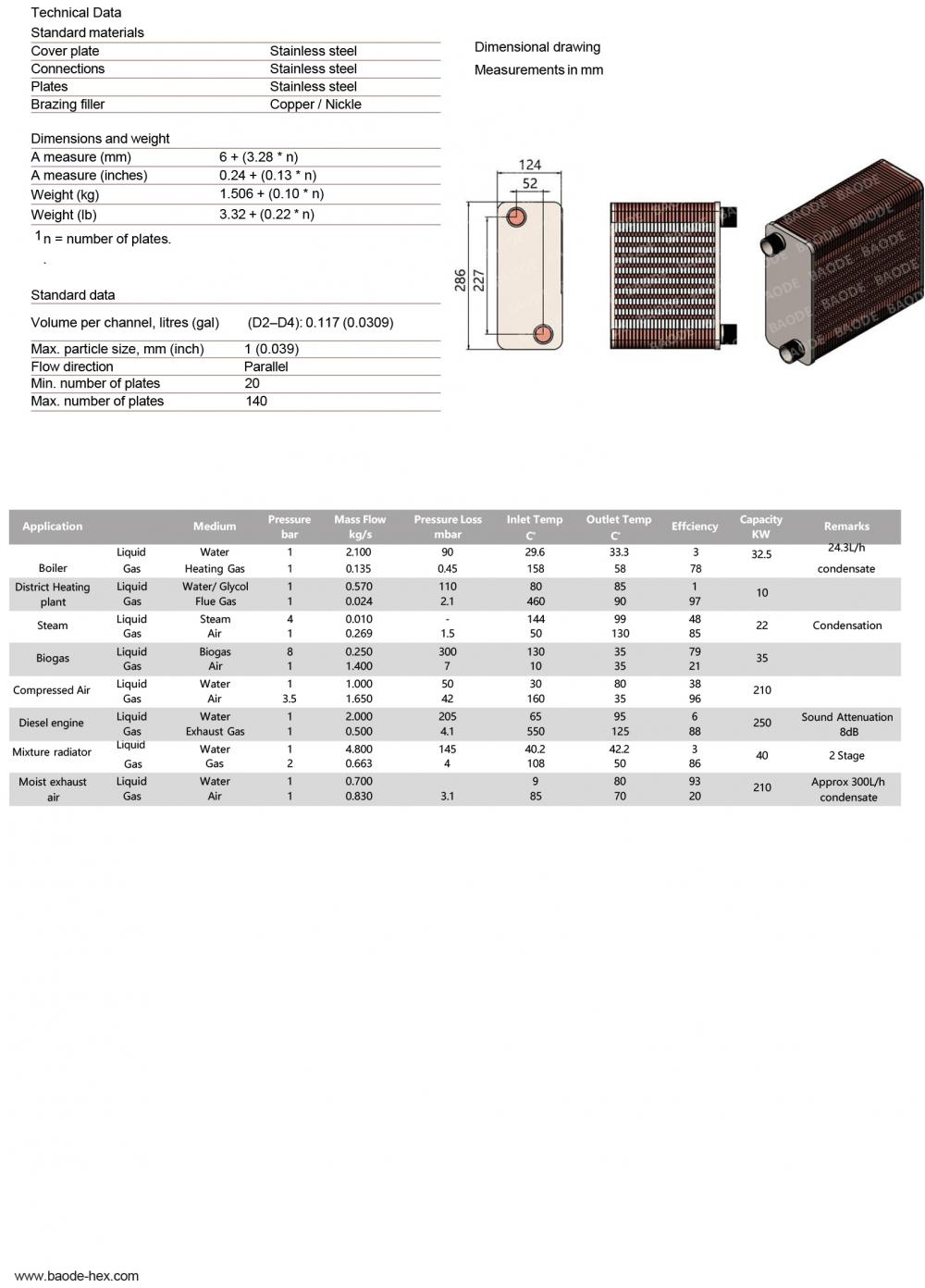

Applications of Air Cross heat exchanger: Condenser. The Air Cross heat exchanger can be built in modular systems, creating the ability to handle larger gas volume extending the performance efficiency to larger systems. Gasket plate heat exchanger has more selection options, the maximum flow can reach 2100m³/h, the maximum flow of brazed plate heat exchanger is only 150m³/h, so under the conditions applicable to each other, the brazed plate heat exchanger volume will be smaller.

Plate heat exchanger is widely used in heating, bathing, air conditioning, metallurgy, hydraulic, chemical, pharmaceutical, food and other fields. Plate heat exchanger is one of the heat exchangers with the highest heat exchange efficiency. It occupies small space and is convenient to install and disassemble.

Application of brazed plate heat exchanger:

Power industry: high voltage transformer oil cooling, generator bearing oil cooling, etc.

Paper industry: bleaching process heat recovery, heating washing slurry, etc.

Textile industry: viscose silk alkali solution cooling, boiling nitrocellulose cooling.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Jiangsu Baode Heat-Exchanger Equipment Co.,LTD

- *Message:

-

Submit

Main Product:

Brazed Plate Heat Exchanger,

Gasket Plate Heat Exchanger,

Air Cross Plate Heat Exchanger,

Flat Plate Heat Exchanger,

Frame And Plate Heat Exchanger,

Welded Plate Heat Exchanger