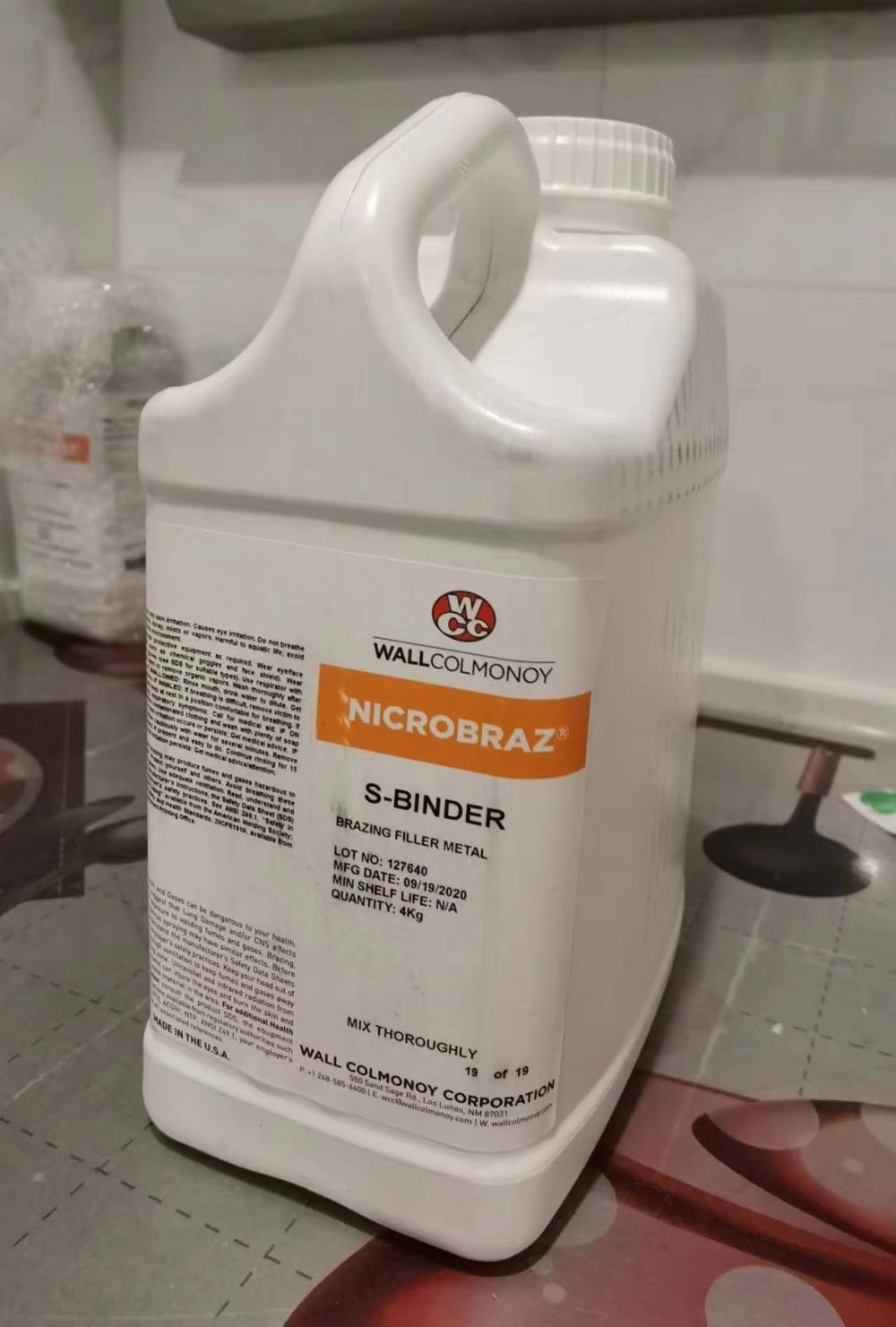

Nicrobraz ‘S’Binder

2 year ago

Nicrobraz ‘S’Binder A binder that can turn brazing filler into solder paste

Nicrobraz ‘S’Binder is a water-based suspended gel that can be mixed with any form of brazing filler to produce a solder paste with thixotropic properties. This paste is perfectly suitable for operation using the Nicrobraz ‘S’ dispensing system, but can also be used with other manual or pneumatic tools. During the stirring process, this material serves both as a medium and a binder. If used properly, it can make the brazing filler remain adhered to the soldering point even when it's fully evaporated (at a temperature of 540°C).

Nicrobraz ‘S’Binder has little impact on high purity gases or vacuum environments in the soldering

context, and even the occurrence of degassing during use isn't much of a concern. As the usage of Nicrobraz ‘S’ paste increases, the degassing action in the vacuum furnace will also increase. If the vacuum furnace is pre-baked, its degassing effect will correspondingly decrease. Even so, baking is almost completely unnecessary because room temperature treatment is sufficient (complete drying requires 4-8 hou

rs). After mixing, the paste should not be quickly placed into the vacuum furnace because moist brazing filler can expand rapidly with rising temperatures. This could lead to the brazing filler flowing into areas that don't need soldering.

Nicrobraz ‘S’Binder does not contain any solvents, is not flammable, is completely non-toxic, and is odorless. There's no need for special ventilation conditions when using this product. However, proper ventilation is always preferable if possible.

Available Forms Storage method: Packaged in 1.5 liters or 3.0 liters. Mixing Steps Initially, use the standard -140 powder brazing filler, roughly stirred at a weight ratio of 88:12. Based on experience, this ratio can be adjusted as needed. This ratio is given priority, the brazing filler must be sieved, and the nozzle length and diameter have specific requirements. A certain pressure is needed during the filling process, and the quantity of filler must be controlled. Care must be taken during stirring to avoid air from mixing into the solder paste, as this can cause the paste to become dispersed when being dispensed from the nozzle. In extensive use, making it into a paste form is advisable and essential.

Usage Steps Refer to Table NSD-2, using the Nicrobraz ‘S’ dosage dispenser.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Shaanxi Xinlong Metal Electro-mechanical Co., Ltd.

- *Message:

-

Submit

Main Product:

Tungsten Heavy Alloys,

Heat Sink,

Electronic Packaging,

Rhenium Alloys,

Tantalum Alloys,

Nickel Based Braze Alloy

You May Also Like