Automobile stand

2 year ago

Compared with other types of machining, this technology can best meet these standards. In addition to processing a wide range of materials, it is also capable of meeting many key specifications.

When processing medical parts for a medical business, it is different from processing parts for other industries. In contrast to most common metal parts that must comply with ISO 9001 quality management, medical parts must comply with additional standards.

As noted by the International Standards Organization (ISO), businesses involved in the design, development, processing, handling, distribution, implementation, or service of medical components must demonstrate that they can provide medical devices and related services that regularly meet the requirements of customers and applicable government regulators.

Your medical components need to be able to demonstrate that they meet the following eligibility requirements before they can be used:

ISO 13485: This is a qualification standard specific to the healthcare industry. It further delves into the details of the ISO 9001 standard relevant to the medical industry, with an emphasis on production process control. It manages several stages of manufacturing: process validation, risk mitigation and quality control. Suppose a company can demonstrate compliance with the standard. Then it would be easier for the company to sell its products globally.

ISO 9001: This is the industry standard for quality assurance and production management. However, it is not limited to any one sector of the economy. It shows that the ISO 9001 standard controls every manufacturing process. It helps save money, makes it easier for the company to grow, and ensures that it meets established standards.

ISO 5001: Energy Management is the single standard used to determine this level of quality. Along similar lines, it provides a guideline that producers can use specific medical components to improve the efficiency of their energy use, thereby improving their overall competitiveness. Note that if they do this, they will be able to further reduce manufacturing expenses.

ISO 14001: Compared to ISO 5001, this quality standard is comparable but more comprehensive. In conjunction with the ISO 5001 standard, it emphasizes the sustainable use of energy, which enables medical component manufacturers to reduce their overall energy consumption and waste output. Any organization that already meets the requirements of this quality standard will undoubtedly implement ISO 50001 in its daily operations.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- WUXI SHINDEN MODERN INTELLIGENT TECHNOLOGY CO.,LTD

- *Message:

-

Submit

Main Product:

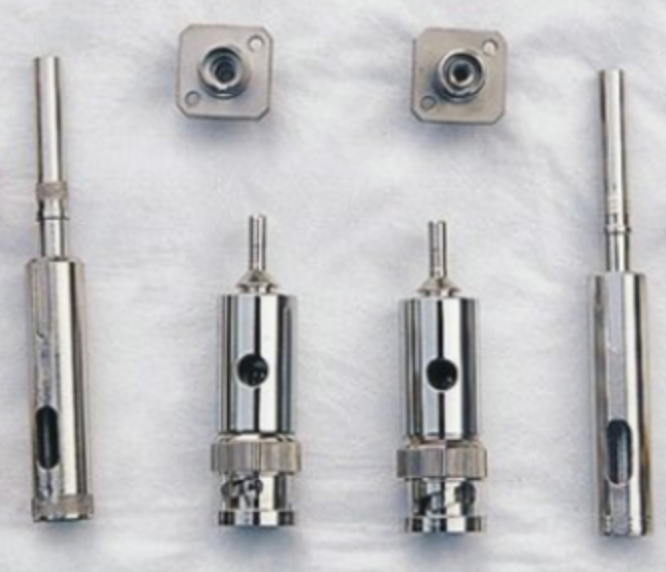

3D CNC Milling Prototype,

CNC Machining,

Automobile Prototypes parts,

Construction Machinery Prototype Parts,

Medical Device Prototype Parts,

Sand Casting

You May Also Like