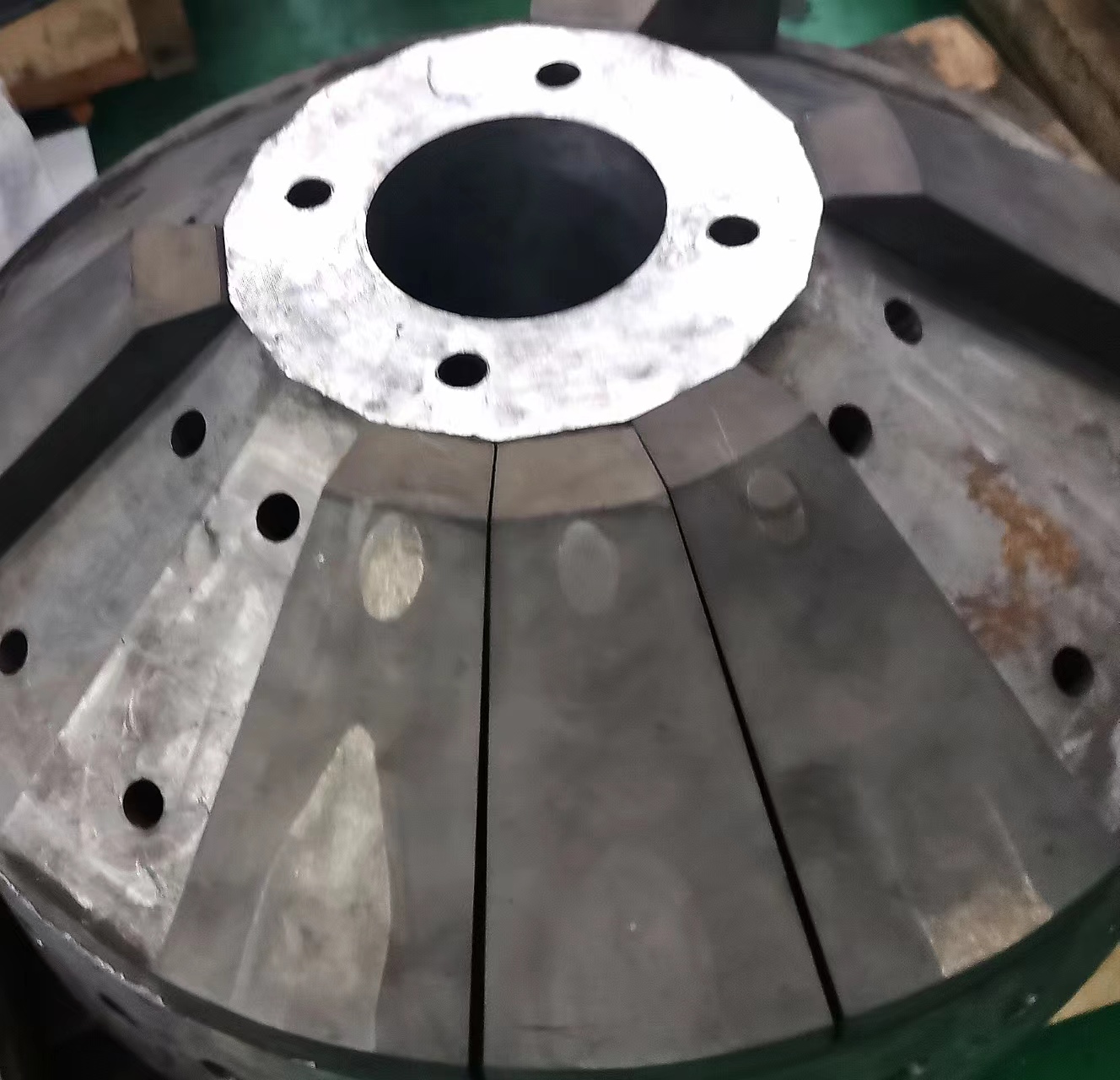

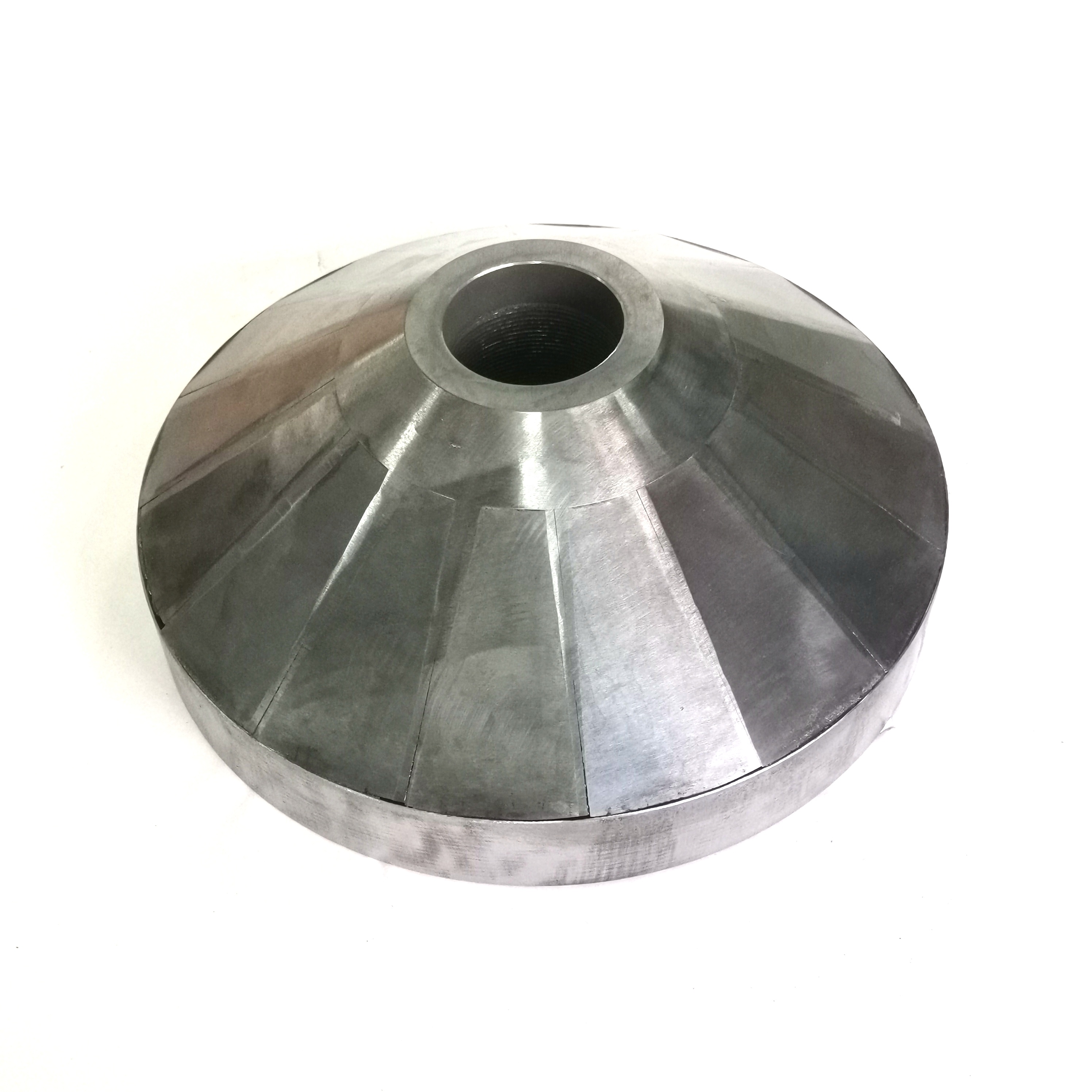

vsi crusher distributor plate packing

2 year agoHigh-Performance Distributor Plate for Vertical Shaft Impact Crushers – Wear-Resistant Solution

As a leading manufacturer of crushing equipment, Zigong Tianyi Industry is committed to providing high-quality wear-resistant parts. Our newly released distributor plate for VSI crushers is designed with advanced hard alloy materials combined with high-chromium steel, ensuring exceptional durability and a long service life. This distributor plate is ideal for high-impact, high-wear applications, significantly boosting crusher efficiency and minimizing downtime.

Product Features and Benefits

-

Combination of Hard Alloy and High-Chromium Steel: The distributor plate is manufactured using hard alloy wear block welded to high-chromium steel, offering superior impact resistance and wear performance. The hard alloy portion uses premium grades like YG8 or WC-Co10, known for their high hardness and oxidation resistance at elevated temperatures, making them ideal for demanding crushing environments.

Recommended Alloy Physical Properties:

- YG8 (Tungsten-Cobalt Alloy):

- Hardness (HRA): 89-91

- Density (g/cm³): 14.6

- WC-Co10:

- Hardness (HRA): 90

- Density (g/cm³): 14.3

Mechanical Properties:

- Exceptional impact resistance and wear resistance, suitable for high-intensity crushing operations.

- Superior oxidation resistance under high temperatures and heavy impact loads, extending the lifespan of the equipment.

- YG8 (Tungsten-Cobalt Alloy):

-

Screw-Fastened Design: The distributor plate is screw-fastened for added stability during high-speed operation, ensuring no loosening, thus enhancing the overall safety and reliability of the equipment.

-

High Durability with Low Maintenance Costs: The combination of premium hard alloys and optimized structural design enhances the distributor plate’s wear resistance by over 30%, reducing the frequency of replacement and lowering operating costs.

Application Scenarios and Compatibility

This distributor plate is widely used in crushing operations for various ores, aggregates, and industrial waste. It is particularly compatible with vertical shaft impact crushers using rotor tip set and tungsten carbide tip. The precise coordination between the distributor plate and rotor ensures even material distribution during high-speed rotation, significantly improving crushing efficiency and ensuring stable long-term operation of the crusher.

Zigong Tianyi Industry is a high-tech enterprise dedicated to the research, development, and production of advanced crushing equipment and wear parts. Our product range, including HPGR wear parts and tungsten carbide tools, is widely applied in industries such as mining, construction, and chemicals. We have built a strong reputation for delivering superior quality and service on a global scale.

In addition to our standard wear parts, we specialize in providing customized crushing solutions that ensure optimal performance and extended service life of your equipment. Our expertise also extends to the manufacturing of high-performance Tungsten Carbide Cutting Tools and PDC drill bits, which are designed for maximum durability in challenging applications.

Choose Zigong Tianyi Industry for reliable and innovative wear parts and crushing solutions tailored to your needs.

Contact Us

If you're interested in our distributor plate for vertical shaft impact crushers or other wear parts such as tip plate and carbide cutting tools, feel free to contact us. Our professional team is ready to provide expert advice and technical support to help you increase production efficiency while reducing maintenance costs.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Zigong Tianyi Industry Co., Ltd

- *Message:

-

Submit

Main Product:

HPGR Hard Alloy Pins ,

Carbide Button,

Rotor Tip Set,

Pin Stud,

Side Stud,

Distributor Plate

You May Also Like