road milling teeth4.10

12 month agoRoad milling teeth

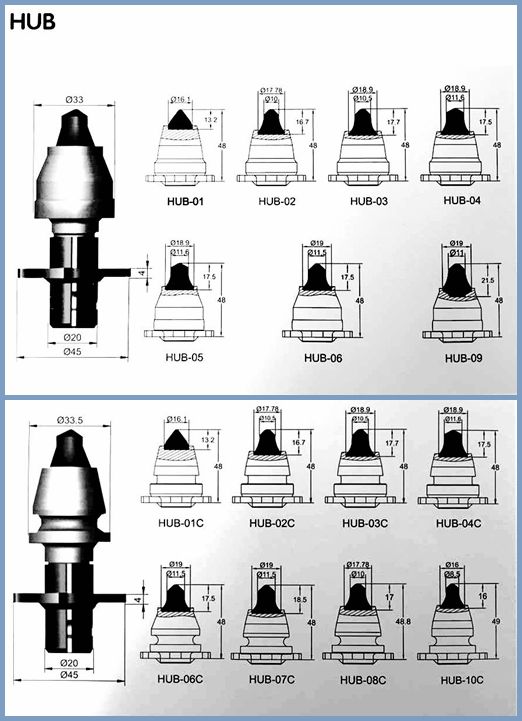

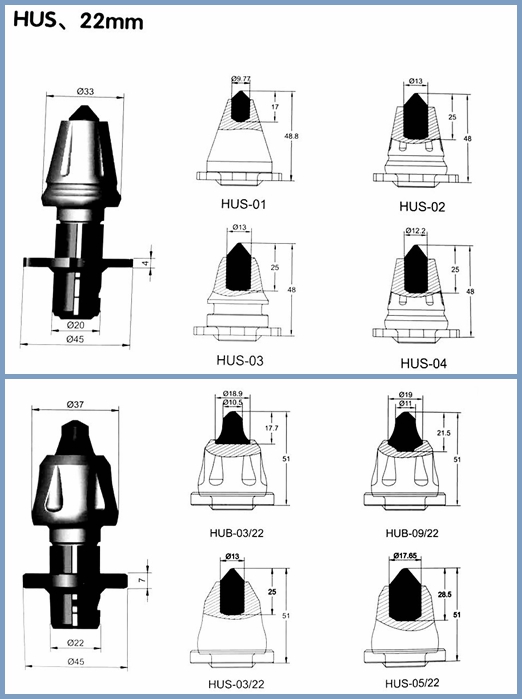

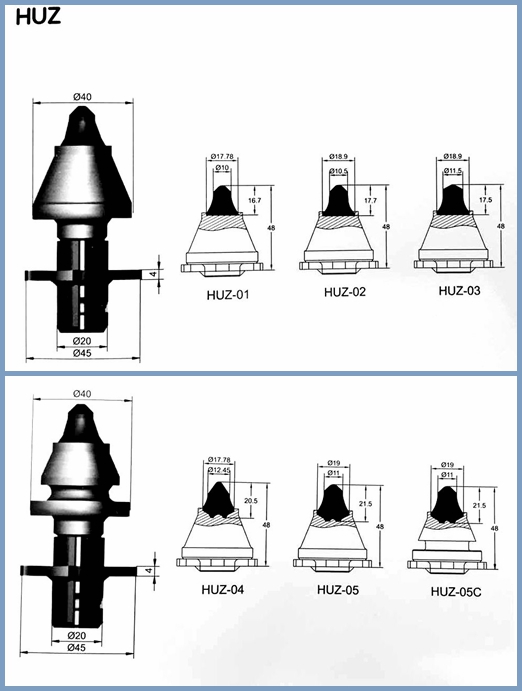

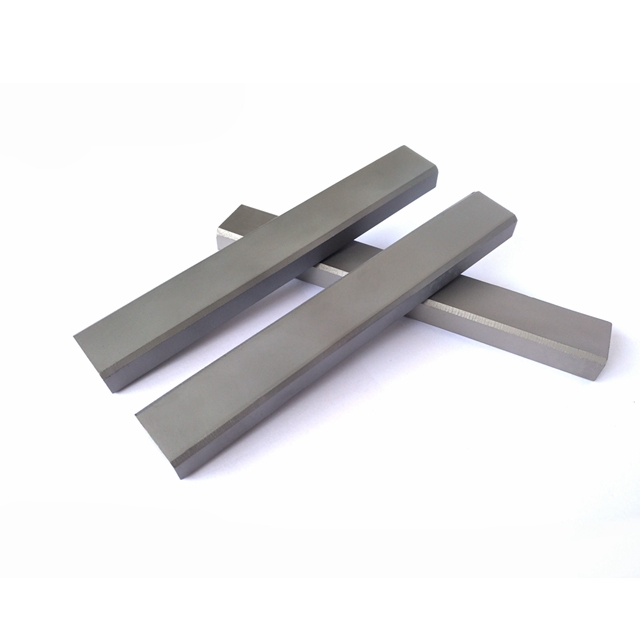

1. Road Milling Bits for Betek, Kennametal & Wirtgen.2. Carbide tip adopting the world's advanced technology to bond cobalt and tungsten carbide particles together to form strong Impact wear resistance, and increase the prolong service life of road milling bits.

3. Self-developed brazing process reduces the desoldering rate to 0.1%-0.2%, guarantees the hold between the carbide tip and the steel body.

4. Integrally molded steel body, the steel body can be guaranteed not broken during use, extend the life of road planning bit.

5. The wear plate material is 65Mn, is trying to protect the bit holder, including in the case of very rough milling material.

Recommed product

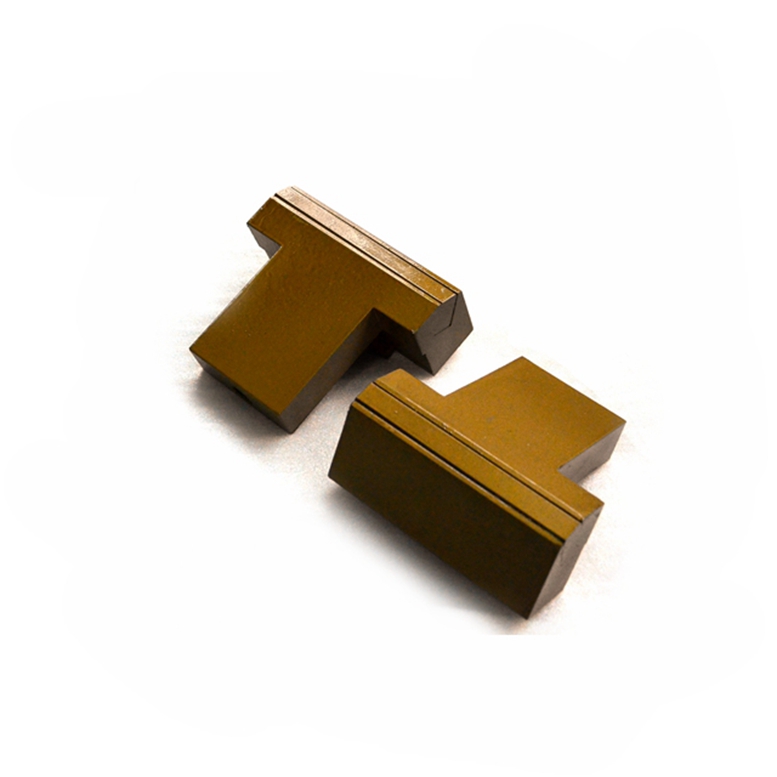

Carbide Boring Head

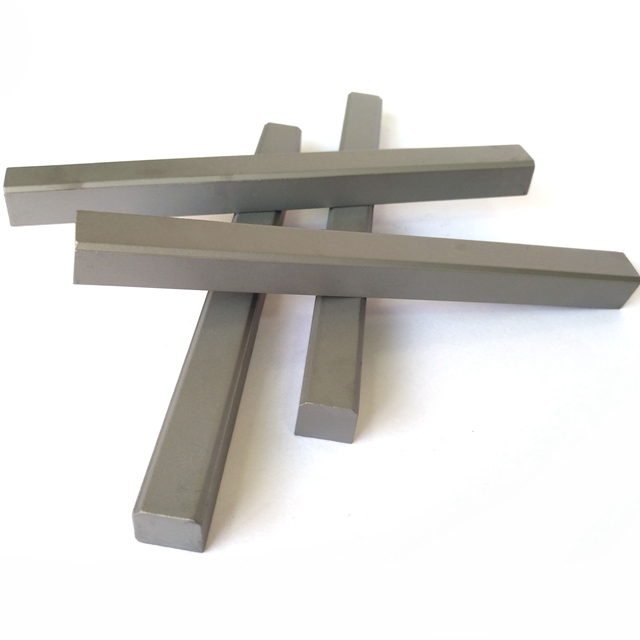

Tungsten Carbide Tip

VSI Rotor Tip

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Zigong Tianyi Industry Co., Ltd

- *Message:

-

Submit

Main Product:

HPGR Hard Alloy Pins ,

Carbide Button,

Rotor Tip Set,

Pin Stud,

Side Stud,

Distributor Plate

You May Also Like