KC-M500PL Laser machine

7 month agoMachine features of laser engraving machine

-

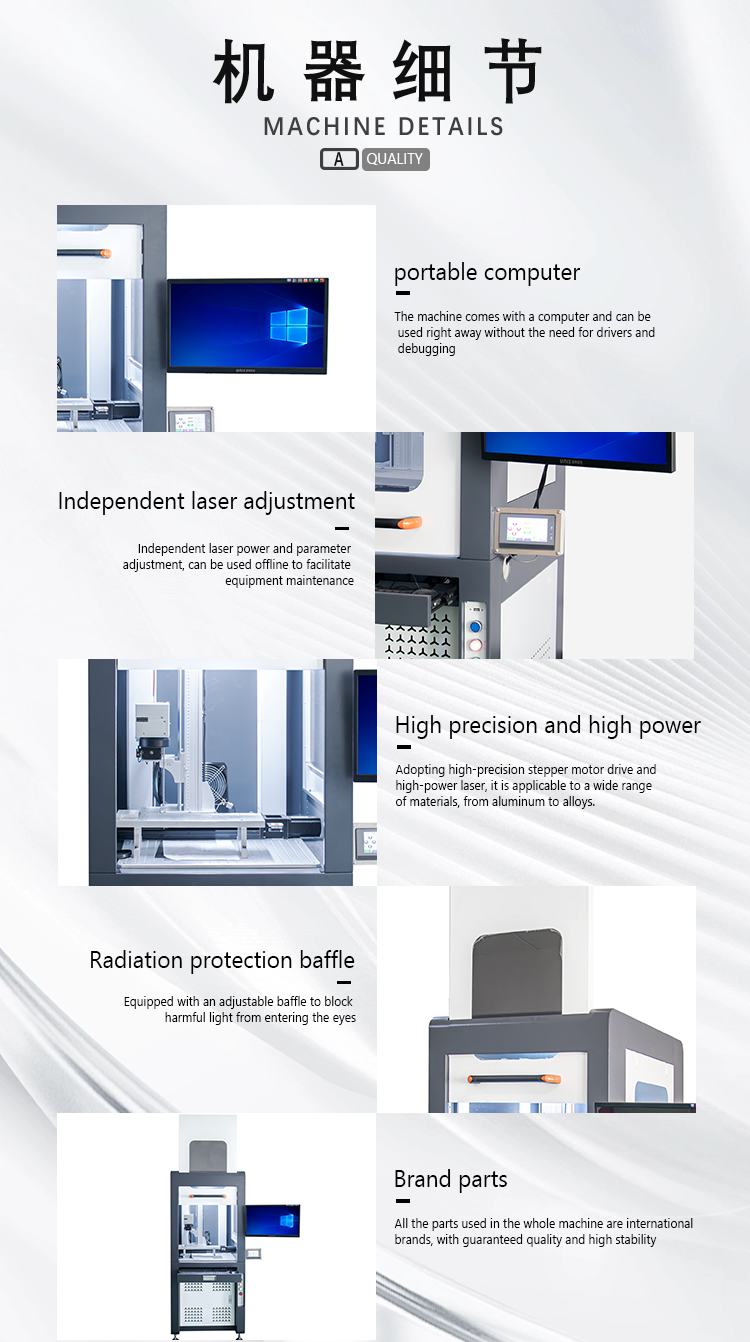

- Integrated overall structure, equipped with automatic focusing system, humanized operation process.

- Imported isolators are used to protect the fiber laser window, enhance stability and laser life.

- The beam quality is significantly improved compared with traditional solid lasers, with fundamental mode (TEM00) output and a focused spot diameter of less than 20um. The divergence angle is 1/4 of that of semiconductor pumped lasers. It is particularly suitable for fine and precise etching.

- The electro-optical conversion efficiency is high, and the power consumption of the whole machine is less than 800W, which is 1/10 of that of lamp-pumped solid laser marking machines, greatly saving energy consumption.

- No special maintenance is required, the service life is long, the size is small, and it is suitable for working in harsh environments.

- Simple and easy to learn, after programming, the equipment automatically completes the etching process of the pattern.

- The whole machine performs laser processing in a closed environment to improve the factory's safety production level.

Working environment requirements for pad plate laser engraving machine

-

-

- The ambient temperature is required to be between 15~40℃.

- The humidity requirement is 40%-80%. To ensure no condensation, it is recommended to install a dehumidifier.

- Power grid requirements: 220V; 50Hz.

- Power grid fluctuation: ±5%, the grid ground line meets international requirements. In areas where the voltage amplitude is more than 5%, electronic automatic voltage and current stabilization devices should be installed.

- There should be no strong electromagnetic signal interference near the installation equipment. Avoid radio transmitters (or relay stations) around the installation site.

- Foundation amplitude: less than 50um; Vibration acceleration: less than 0.05g. Avoid a large number of stamping and other machine tools nearby.

- Equipment space requirements must be smoke-free and dust-free, and avoid working environments with severe dust such as metal polishing and grinding.

- Air pressure: 86-106kpa.

- Anti-static floors should be installed in some environments to strengthen shielding, etc.

-

| Technical parameters | |||

| Performance | parameters | Total wattage | 0.8KW |

| F=160mm Range:100mm×100mm | |||

| Scan speed | Line scan≤10000mm/s | ||

| MIn line width | 0.015mm | ||

| Single scan depth | ≤0.003mm | ||

| Repeatability | ±0.01mm | ||

| Min Character | 0.3mm | ||

| Laser head | Wattage | 20W | |

| Single pulse energy | <0.1mJ | ||

| Beam quality M² | <1.3 | ||

| Wavelength | 1064nm | ||

| Soft-system | The control software KC-soft supports Windows platform, is easy to operate, powerful, and compatible with PLT, BMP and other file formats output by AutoCAD, Coreldraw, Photoshop and other software. It can mark patterns, barcodes, Chinese and English characters, product serial numbers (automatic number jump), and can directly use SHX and TTF fonts in the software. It can also adjust the size, spacing and arrangement of characters very conveniently. | ||

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- KC Printing Machine (Group) Limited

- *Message:

-

Submit

Main Product:

Automatic Screen Printing machine,

Automatic Pad Printing machine,

Automatic Hot Foil Stamping Machine ,

Pad Printers,

Screen Printers,

Hot Foil Stamping Machines

You May Also Like