Aluminum Nitride Ceramic Substrate For Thick Film Circuits

The aluminum nitride (AlN) ceramic substrate for thick - film circuits is a vital component in the field of electronics. It provides a stable base for the construction of thick - film circuits, which are used in various high - power and high - frequency applications.

1. Material Properties

(1) High Thermal Conductivity

AlN ceramic substrates have excellent thermal conductivity, usually in the range of 170 - 230 W/(m·K). This high thermal conductivity enables efficient heat dissipation from the thick - film circuits. As thick - film circuits can generate a significant amount of heat during operation, the substrate helps to maintain a suitable operating temperature, preventing overheating and ensuring the reliability of the circuit.

The efficient heat transfer also allows for better performance and longer life of the components on the circuit, as they are less likely to be damaged by excessive heat.

(2) Superior Electrical Insulation

These substrates possess outstanding electrical insulation properties. They have a high dielectric strength and a low dielectric loss, which means they can effectively isolate electrical signals. The volume resistivity of AlN is usually greater than 10¹⁴ Ω·cm. This property is crucial for preventing electrical leakage and short - circuits in thick - film circuits, especially in high - voltage and high - frequency applications.

The good electrical insulation also helps to reduce electrical noise and interference, resulting in a more stable and accurate performance of the circuit.

(3) Chemical Stability

Aluminum nitride ceramic substrates are chemically stable. They can resist the corrosion of many chemicals, such as acids and alkalis. This chemical resistance is beneficial in various industrial and environmental conditions, ensuring the long - term durability of the substrate and the circuit it supports.

2. Compatibility with Thick - Film Circuits

(1) Surface Properties

The surface of the AlN ceramic substrate is usually smooth and flat, providing a good platform for the printing and sintering of thick - film pastes. The smooth surface helps to ensure the uniformity and quality of the thick - film layer, which is essential for the proper functioning of the circuit.

The substrate can also have a suitable surface roughness adjusted according to the specific requirements of the thick - film circuit, to enhance the adhesion between the substrate and the thick - film layer.

(2) Thermal Expansion Matching

The coefficient of thermal expansion of AlN ceramic is relatively low and matches well with many thick - film materials. This compatibility helps to prevent the detachment or cracking of the thick - film layer due to temperature changes during the operation of the circuit. It ensures the integrity and stability of the circuit structure.

3.Aluminum Nitride Substrate Products advantages:

1. Source quality control, from raw material research and development to ceramic products, all are independently developed and produced.

2. Standard thermal conductivity ≥ 175W/m · k, ultra-high thermal conductivity ≥ 200W/m · k.

3. Provide customized services, including grinding type, instant burning type, high bending resistance, high thermal conductivity, polishing type, laser marking type, etc

Board.

4. Suitable for various types of metalization: DPC, DBC,TPC,AMB, Thick film printing, thin film printing, etc.

5. The thinnest thickness can reach 0.10mm.

4.Performance Parameter Table Of Aluminum Nitride Ceramic Substrate

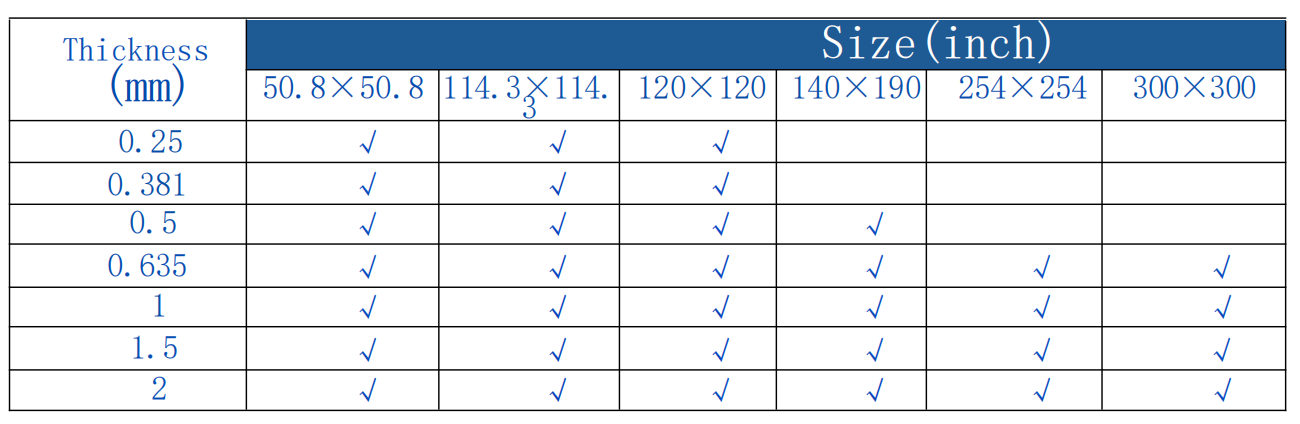

5.Production dimensions of aluminum nitride ceramic substrate

We offer a variety of advanced ceramics, including alumina ceramics, aluminum nitride ceramics, silicon carbide ceramics, silicon nitride ceramics, and ceramic metallization materials, to improve and expand the performance of your products, processes, or systems. Whether you need high temperature stability, high hardness and wear-resistant surface, increased stiffness to resist weight radiation, anti-corrosion barrier or low thermal expansion rate, we can provide them. We can provide significant performance and cost advantages to meet your needs.

Welcome to contact us for more information.