CMM optical surface testing

5 month agoMG-Optics have one ZEISS Coordinate Measuring Machine (short for CMM) for optical test. It is used in the milling and grinding stage to control the mechanical form tolerances and surface accuracy of optical components preparing for the polishing process. MG-Optics provide optical dimension metrology service as customer request, leverage ZEISS CMM to measure the critical dimensions of the optical component. This may include diameters, thicknesses, flatness, coaxiality,concentricity,cylindricity or other specific features as per the custom requirements. the optical test report will be submitted with measurement datas and tolerance analysis.

CMM Contura Performance and Indicators

x1500mm,y2000mm,z1000mm.

Measurement of optical components with an aperture of 1000 mm;

measurement accuracy of 2.4+L/400um;

surface measurement function;

force measurement adaptive function;

active vibration isolation technology minimizes measurement results affected by installation conditions and environmental interference.

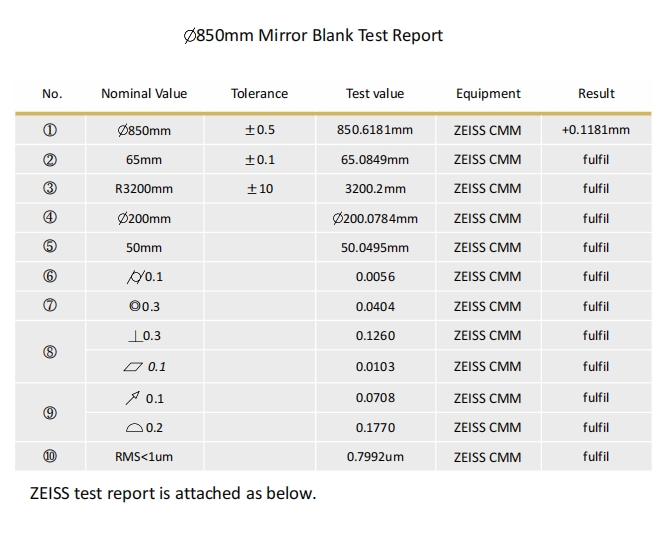

The test report sample is as follows:

If you are interested with our products, Just send us your drawings or specifications, we will begin preparing a quotation for you.

Contact with our professional technician engineer now!

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Mirrorganize Optical Technology (Foshan) Co.,Ltd

- *Message:

-

Submit

Main Product:

optical aspheric mirror ,

custom CGH,

optical flat,

optical Mirror blank,

optical metrology,

optical system

You May Also Like