filter press49

3 year agoMembrane Filter Press for Pharmaceutical Industry

Filter press according to the filter plate shape is divided into square filter press and round filter press, more common on the market of filter plate is square, circular filter plate of filter press is less, only a few manufacturer in current domestic can produce round high pressure membrane filter press, especially in the field of ultrahigh pressure filter press technology accomplished manufacturers is less and less. High pressure circular filter press is widely used in solid-liquid separation of stone wastewater, ceramics, kaolin, bentonite, active soil, building materials and other industries due to its high filtration pressure and low water content of cake.

Characteristics of circular plate high-pressure membrane filter press:

1, the system uses mechanical and electrical equipment liquid, PLC system control, complete automatic pulling plate, practical operation is simple, reduce personnel cost;

2, the selection of automatic turning plate liquid collection, solve the problem of the slag water separation is not easy, improve the quality of products and reduce the burden of natural environment cleaning;

3, the filter plate is imported polymer PE material, high pressure stamping 1 forming, longer service life;

4, according to the characteristics of raw materials, the proportion of different general than ordinary filter press can increase the solid content of nearly 10%;

5, high standard production process and technical application, all aspects, to ensure the high quality of each equipment, is the ideal solid-liquid separation equipment machine equipment.

Advantages of round plate high-pressure filter press:

1, choose ring filter plate design concept, with stable operation, feeding pressure is very large, low water content of cake.

2, the selection of high strength toughness polypropylene material, high compressive strength.

3. Linear sealing ring is selected for the filter chamber, which has good airtightness and ultra-high pressure resistance.

Specifications of Membrane Filter Press Machine:

| Model |

Filter Area (m2) |

Plate Size (mm) |

Cake Thickness (mm) |

Volume (L) |

Plate QTY (PCS) |

Pressure (MPa) |

Dimensions (mm) |

| XMGZ 30/870 | 30 | 870*870 | ≤30 | 427 | 23 |

Feeding: ≤1 MPa, Squeezing: ≤1.5 MPa |

3880*1250*1300 |

| XMGZ 40/870 | 40 | 534 | 29 | 4270*1250*1300 | |||

| XMGZ 50/870 | 50 | 676 | 37 | 4790*1250*1300 | |||

| XMGZ 60/870 | 60 | 818 | 45 | 5310*1250*1300 | |||

| XMGZ 70/870 | 70 | 960 | 53 | 5830*1250*1300 | |||

| XMGZ 80/870 | 80 | 1103 | 61 | 6350*1250*1300 | |||

| XMGZ 50/1000 | 50 | 1000*1000 | 665 | 27 | 4270*1500*1400 | ||

| XMGZ 60/1000 | 60 | 808 | 33 | 4700*1500*1400 | |||

| XMGZ 70/1000 | 70 | 950 | 39 | 5130*1500*1400 | |||

| XMGZ 80/1000 | 80 | 1093 | 45 | 5560*1500*1400 | |||

| XMGZ 100/1000 | 100 | 1378 | 57 | 6410*1500*1400 | |||

| XMGZ 120/1000 | 120 | 1663 | 69 | 7260*1500*1400 | |||

| XMGZ 80/1250 | 80 | 1250*1250 | ≤35 | 1364 | 29 | 4830*1800*1600 | |

| XMGZ 100/1250 | 100 | 1680 | 37 | 5440*1800*1600 | |||

| XMGZ 120/1250 | 120 | 2092 | 45 | 6060*1800*1600 | |||

| XMGZ 140/1250 | 150 | 2547 | 55 | 6820*1800*1600 | |||

| XMGZ 160/1250 | 160 | 2729 | 59 | 7130*1800*1600 | |||

| XMGZ 180/1250 | 200 | 3457 | 73 | 8200*1800*1600 | |||

| XMGZ 200/1250 | 240 | 4093 | 89 | 9420*1800*1600 | |||

| XMGZ 250/1250 | 250 | 4276 | 91 | 9570*1800*1600 | |||

| XMGZ 200/1500 | 200 | 1500*1500 | 3866 | 49 | 7140*2200*1820 | ||

| XMGZ 250/1500 | 250 | 4399 | 61 | 7730*2200*1820 | |||

| XMGZ 300/1500 | 300 | 5199 | 73 | 8720*2200*1820 | |||

| XMGZ 350/1500 | 350 | 6132 | 85 | 10110*2200*1820 | |||

| XMGZ 400/1500 | 400 | 6932 | 99 | 11260*2200*1820 | |||

| XMGZ 450/1500 | 450 | 7731 | 111 | 12250*2200*1820 | |||

| XMGZ 500/1500 | 500 | 8665 | 123 | 13240*2200*1820 | |||

| XMGZ 500/1999 | 500 | 2000*2000 | ≤40 | 9686 | 69 | 10310*2850*2400 | |

| XMGZ 600/2000 | 600 | 11900 | 85 | 11580*2850*2400 | |||

| XMGZ 700/2000 | 700 | 13838 | 99 | 12740*2850*2400 | |||

| XMGZ 800/2000 | 800 | 15775 | 113 | 14100*2850*2400 | |||

| XMGZ 900/2000 | 900 | 17851 | 128 | 15365*2850*2400 | |||

| XMGZ 1000/2000 | 1000 | 19788 | 142 | 16625*2850*2400 |

Why choose Shen HongFa Filter Press

We have professional team in sludge filteration which have many research staffs who have devoted themselves to the industry for more than 20 years, and our High-Efficiency Circular Filter Press for Sludge, saled all over the world.

1),Long history : our factory established in 2014,and we are the leading enterprise in filter press industry .

2),we are one of the main constitutor of press filter regulations.

3),we are a professional team which have many research staffs who have devoted themselves to the industry for more than 20 years.

4),We offer different material's filter plate according to different industry , while other providers couldn't make it .

5), Our products are sold to many companies which most of them are top500 .

6),We manufacture the filter plate ourselves , so we could guarantee its quality ,while other providers buy it from others

WORK SHOP

PRODUCT SHOW

1) The plate-frame sludge filter press is an intermittent solid-liquid separation device.

2) It consists of a filter plate and a filter frame arranged to form a filter room. Under the pressure of the feed pump, the feed liquid is sent to each filter room through filtration.

3) Medium, separating solids from liquids. It has the advantages of good separation effect, wide application scope, simple operation, and low investment.

4) Especially for the separation of viscous material, it has unparalleled superiority

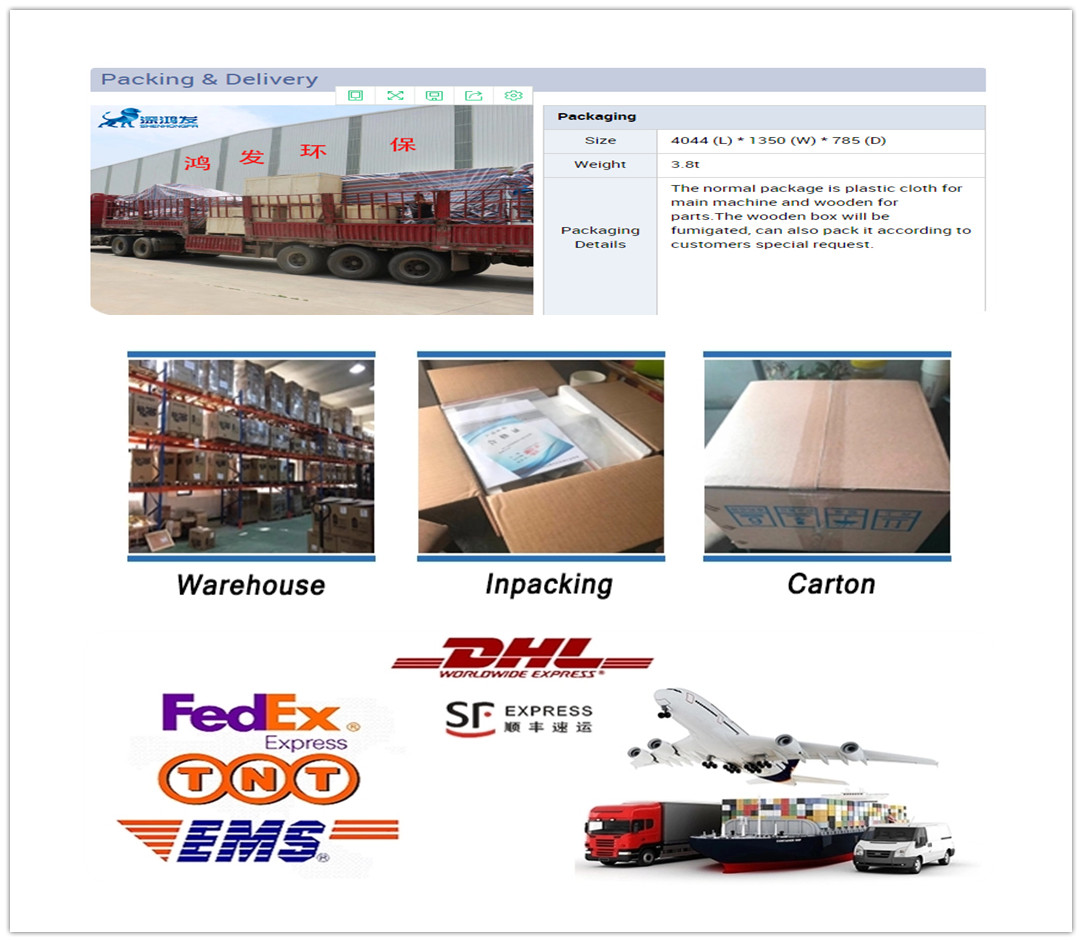

PACKING AND DELIVERY

Our Engineering Project

FAQ:

-------1. How to buy your interested products?

You can provide us the water sources, water quality, flow rate and ground area, material requirements about your project (More details, please contact us).

-------2. How to pay?

L/C or T/T are acceptable.Usually, 50% payment in advance, 50% payment before delivery.

-------3. What is the delivery time?

It depends on order quantities. Generally speaking, the delivery time will be within 1 months.

-------4. How to pack the products?

We use standard export package.If you have special package requirements, we will pack as you required, but the fees will be paid by customers.

-------5. How to install after the equipment arriving destination?

We will provide detailed illustrations to you. If it is necessary, we will send technicians to help you.

-------6. How long is the validity?

The validity is 12 months after installation

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Shenzhen Hongfa Environmental Protection Equipment CO., LTD

- *Message:

-

Submit

Main Product:

Filter Press,

Plate and Frame Filter Press ,

Chamber Filter Press,

Membrane Filter Press,

Wastewater Treatment ,

filter press pump