Large batch Ceramic Lined Carbon Steel Pipe

3 year ago

Product Introduction

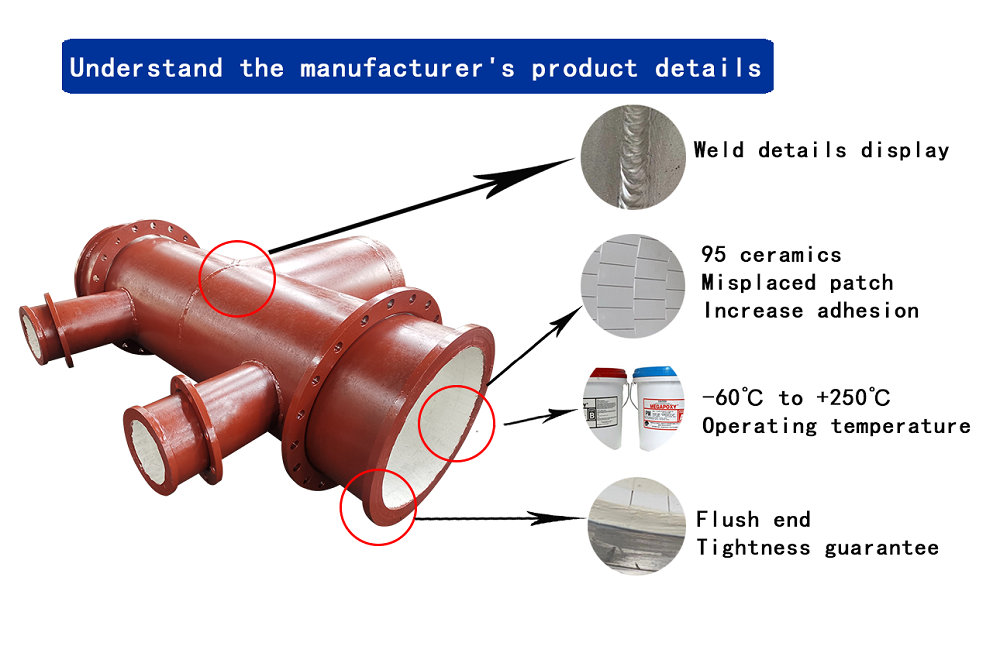

The inner Ceramic Lined Pipe is composed of three layers: the outer steel pipe layer, the corundum layer, and the ceramic adhesive layer. The inner ceramic layer of Ceramic Pipe Fittings is white from the surface. Ceramics are generally 95 ceramics, and the temperature is generally below 200 °C.

At present, the common ceramic sheets for Ceramic Lined Steel Pipe lining are: ceramic block, dovetail mutual pressure, welded type, inlaid type, slotted type, etc., which have the characteristics of wear resistance and long service life.

Product performance

1. Large hardness

Rockwell hardness HRV 80-90

2. High wear resistance

Wear resistance is equivalent to 20-30 times of high manganese steel

3. Light weight

Its density is 3.9g/cm³, which is only half that of steel, which can greatly reduce the equipment load

4. Imported glue

Magbao imported glue, bonding strength: 10Mpa, working temperature: -60℃ to +250℃, welding type, wear resistance up to 800℃

Specifications

Technical parameters of wear-resistant ceramic pipes

Brand: Jianghe

Manufacturer: Jiangsu Jianghe Machinery Manufacturing Co., Ltd.

Pipe diameter: ≥DN100

Steel pipe thickness: ≥4mm

Steel pipe material: Q235 or stainless steel

Ceramic thickness: 4mm, 6mm, 8mm, 10mm, etc.

Connection method: flange, welding, casing, V-connector

Working pressure: ≤1.0MPa (other pressures need to be communicated with customer service)

Ceramic sheet technical indicators

Ceramic marking: 92-95

Bulk density: 3.9g/cm³

Tensile strength: 1030MPa

Flexural strength: 212MPa

Hardness HRV: 80-90

Manufacturer Service

1. Free technical answers

2. Free CAD or 3D drawing

3. Paid surveying and mapping services

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Jiangsu Jianghe Machinery Manufacturing Co., Ltd.

- *Message:

-

Submit

Main Product:

Wear Resistant Pipe,

Bimetal Wear-Resistant Pipe,

Wear Liners,

Wear Resistant Elbow,

Burner In Thermal Power Plant,

Slurry Pump