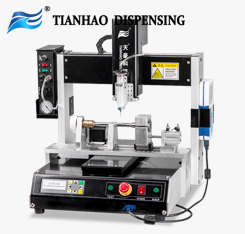

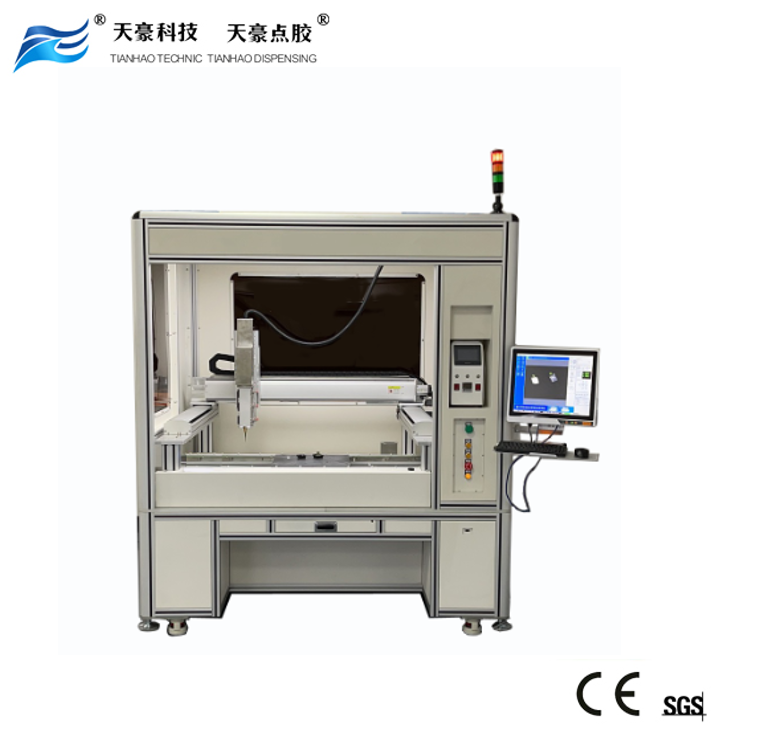

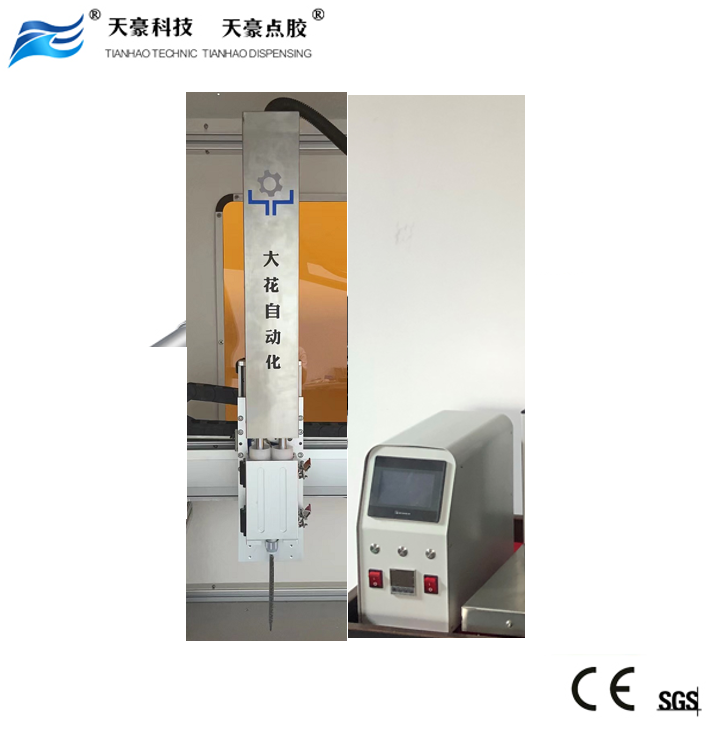

industrial robot with CAMERA teaching edit program functions and camera alignment system TH-2004AE1

3 year ago

Dispensing Robots with CAMERA teaching functions and camera alignment system.

Function

1) Processing with bonding, coating, sealing, filling, drop, linear/ arc/ round gluing, etc. 2) Dispense in point, line, surface, arc, circle and irregular curve, and triaxial linkage function is available.

Liquid Materials

Silicon, oil, adhesive ,UV glue, solid , Epoxy resin , Silver cream, lubricants, instant glue, water, milk, honey, butter, adhesives, sealants, grease, inks and other fluids as part of their assembly processes

Features

Accurate fiducial identification and alignment for accurate repeatable dispense placement

Proprietary vision-controlled software developed for simple user-friendly setup,programming and operation.

Computer programming, simple operation interface system, simple and easy to learn, with perfect process parameter editing function, equipped with dedicated guidance.

High Accuracy, advanced motion control with integrated vision allows for increased production capacity, faster cycles, improved quality over more tedious and complex projects

According to different needs, the products can be placed at any angle/quantity, without the need for automatic identification and completion of glue dispensing operations, can be dotted, 3DLines, Circles, Arcs, Continuous Paths, XYZ simultaneous (CP) 3D irregular curves, dispensing speed/dispense amount/ The dispensing trajectory (spatial points, lines, arcs, etc.) can be set separately.

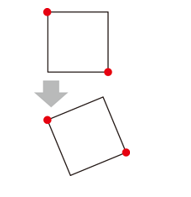

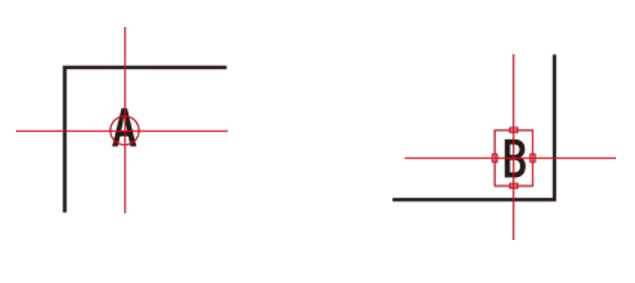

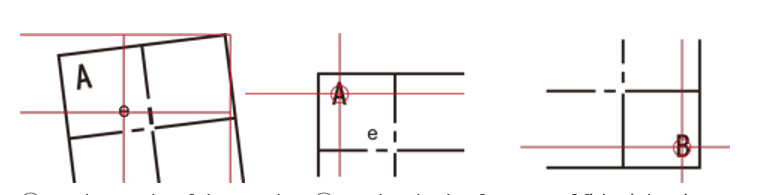

Block offset

faster and less programming

Image alignment

Image correction

dispensing

Dispenser for 2K Cartridge of 400ml

continuous.

* Adopt microcomputer integration, imported accessories, screw electric push method, no need air pressure, machine adopts motor

drive, double guide rail and screw driving mode,keep stable and high efficiency glue output and, and not affected by air

pressure and viscosity.

3. Through the touch screen to set push glue speed and moving speed, set the position of the push rod and the return function of

the push rod. Return and reset only need to be reset for 3 seconds.

|

ITEM

|

TH-2004AE vision system

|

|

X/Y/Zworking range

|

Customized

|

|

Motor control axis

|

3 axis

|

|

Vision point system

|

1000W pixel ultra-high-speed camera system

|

|

Vision range Imaging

|

500X500mm(customized)

|

|

Single detection time

|

0.1s

|

|

software

|

Special software for 3 axis

|

|

Control method

|

special multi-axis motion control card + industrial computer + computer display

|

|

Display mode

|

22 inch LCD Screen

|

|

XY/ZMaximum Load

|

15 kg /10 kg

|

|

Repeatability

|

0.01mm

|

|

Resolution

|

0.001mm

|

|

XY/Z Speed

|

0-600 /Sec

|

|

Drive System

|

Panasonic servo motor

|

|

Transmission

|

Precision Linear Guides and screw

|

|

Patterns

|

3DLines, Circles, Arcs, Continuous Paths, XYZ

simultaneous (CP) 3D |

|

Power

|

AC220V±10% 50/60Hz

|

|

Air pressure

|

0.5-0.7mpa/cm²

|

|

Dimensions (WxDxH) mm

|

1000*1950*1400mm

|

|

Weight

|

530KGS

|

|

Standard

|

CE Approved

|

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- CIXI TIANHAO ELECTRIC CO.LTD

- *Message:

-

Submit

Main Product:

Dispensing robot,

glue dispenser,

thread coating machine,

assembly line,

production line,

customized equipment