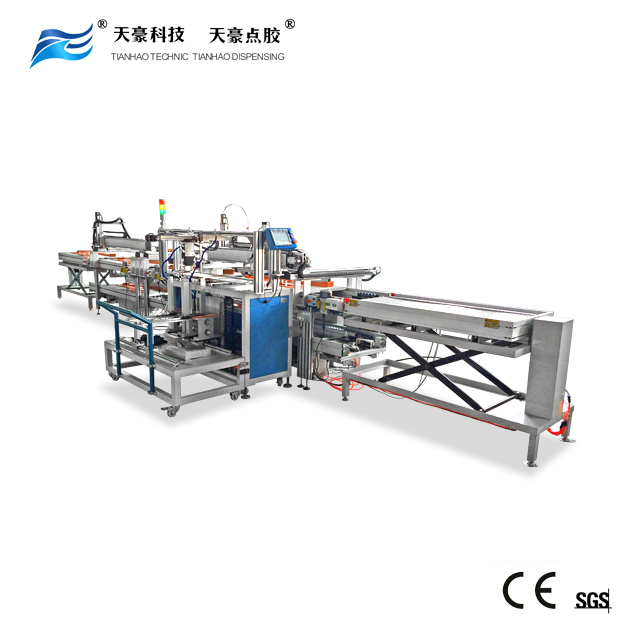

Full automatic assembly machine for led light and led bulb lamp TH-2004AE1

3 year ago

Full automatic bulb production line and assembly line

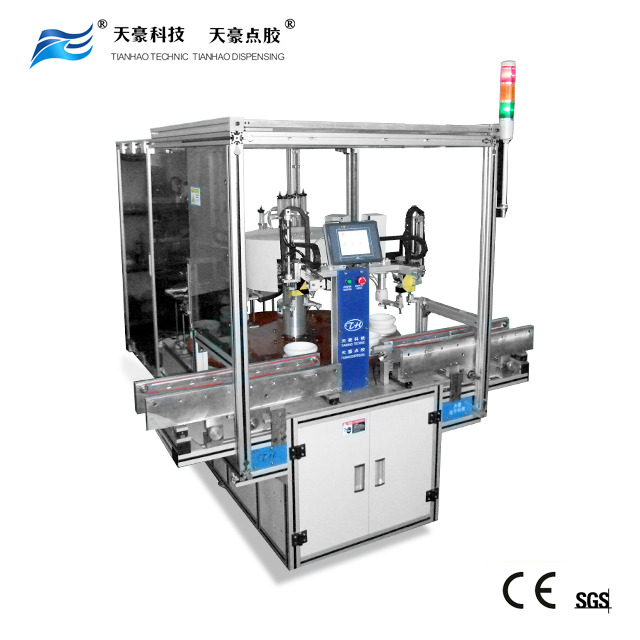

glue dispensing machine

Product introduction

TH-2004AE customized machine accoding to client require

Function

Semiconductor Packaging PCB fixed and protection of electronic components LCD glass board encapsulation Mobile phone keypad board coating or dispensing Speaker Dispensing battery compartment sealing Motor vehicle parts coated mechanical Metal parts coating Quantitative gas, liquid filled coating Chip bonding

Liquid Materials

Silicon, oil, adhesive ,UV glue, solid , Epoxy resin

Features

Specification:

finish automatic pressing cap and glue dispensing.assembly line

According to your company's product and production require, we design an equipment of the following technical parameters.

* Power: 380 volts three-phase,60HZ

* Production ratio:8 Sec/pcs

* Work Air pressure:6-7KG

* Equipment characteristics

* Each-station to install a sensor that every work station self-identification to work

* The machine operation of a processed product does not send product with finished out, the machine will automatically be prompted.

* The machine running, if without glass, the machine will automatically be prompted.

* when replace the product, you should manual adjusting as following

* To select the number of products in the computer,the computer will automatically select the product dispensing glue location

and dispensing volume

* By the hand take the lights fixed mould on the work card seat.

* By the hand take the glass into the glass fixed mould

* By the hand fix the glass module on the machine arm.

* By the hand take the grasp the product module on the machine arm

* By the hand adjusting the feeding material belt and dispensing glue location of the product

* Valve protection。

* The glue tube in the valve should to replace every day,

* For a short period of time let the glue to be quickly curing, you should add acceleration solvent.

* If machine want short time stop work, please take a container on the valve. so that prevent the valve end be cured by the glue

* If machine long time no work, it should flow full glue out in the valve.

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- CIXI TIANHAO ELECTRIC CO.LTD

- *Message:

-

Submit

Main Product:

Dispensing robot,

glue dispenser,

thread coating machine,

assembly line,

production line,

customized equipment