Jiema Production Overview

3 year ago

Jiema Water-Cooled Marine Plate Heat Exchanger with ISO CE Certification consists essentially of heat transfer plates, gaskets and a clamping device. Owing to its structure and heat exchange principle, it is characterized by compact structure, small floor area, high heat transfer coefficient and operation flexibility, wide application range, small heat loss, easy installation and cleansing, etc.

Component Materials

Heat Exchanger Plate: SUS304, SUS316L, SMO254, titanium, nickel, Hastelloy alloy

Gasket seal: NBR, H-NBR, EPDM, food pad, fluorine rubber, silicon rubber

Frame: Carbon steel, stainless steel, coated stainless steel

Clamping bolt: Galvanized carbon steel, stainless steel

Interface: Rubber, carbon steel, stainless steel

Guide bar: Galvanized carbon steel, stainless steel

Gasket Material and Application

|

Material Description |

Code |

Applicable Temperature (ºC) |

Anti-corrosive Performance and Applicable Occasions |

|

NBR |

N |

-20~110 |

Hot air, water, non-polar oil, mineral |

|

EPDM |

E |

-50~150 |

Vapor, polar chemical medium, alcohol, weak acid, weak alkali and oxidizing agent, etc. |

|

Fluorine Rubber |

F |

0~180 |

Inorganic acid, alkali, mineral oil and |

|

Silicon Rubber |

Q |

-65~230 |

Resistant to cold current and dry hot |

Features

1. High Efficiency

2. High Heat Transfer Rates

3. Modularity For Flexibility

4. Compact Design

5. Self-Cleaning Action

6. Easy to maintance

FAQ

1. Apart from a Marine Plate Heat Exchanger, what are the necessary materials that I need for maintanance?

Spares including Heat Exchanger Plate&Gasket, Flange, bolts and nuts et cetera are all available in our factory as replacement/maintanance.

2. How does a Marine Plate Heat Exchanger Work?

Each unit consists of a series of grooved plates that are individually gasketed and pressed tightly together by compression bolts within a frame. Fluids enter and exit the PHE through portholes in one or both ends of the frame. Within the unit, the fluid to be heated or cooled flows down one side of each plate, while the heating or cooling medium flows in the opposite direction across the other side. The huge temperature difference created by these opposite flows allows maximum heat transfer efficiency for closest possible approach temperature .

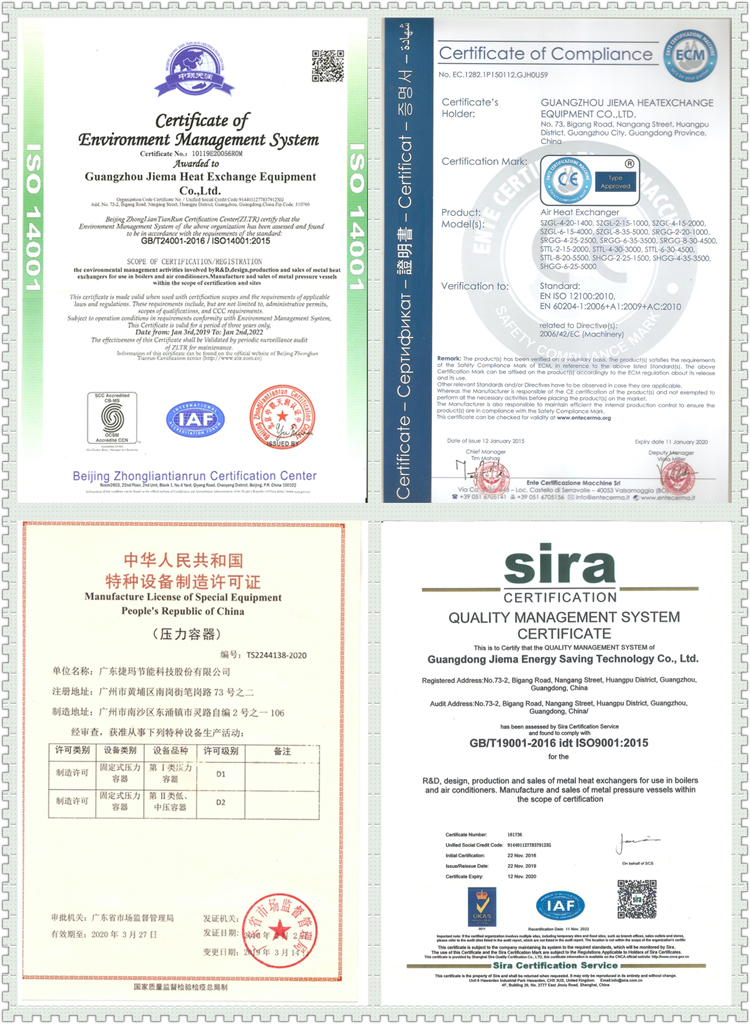

Real-time Factory Shot and Certificate Obtained

Similar Video Recommendation

You May Also Like

If you are interested in the product, contact Bossgoovideo.com for more information

- *To:

- Guangdong Jiema Energy Saving Technology Co.,Ltd

- *Message:

-

Submit

Main Product:

Plate Heat Exchanger,

Shell And Tube Heat Exchanger,

Air Heat Exchanger ,

Water Chiller,

Shell and Plate Heat Exchanger,

Cooling Tower

You May Also Like